How about a CNC machining tool. CNC, short for "Computer numerical control. We are going to talk about a type of machine that, programmed by computer, cut and shaped the items we used. These Vedette machines are some of the most powerful you can get your hands on that will cater for a wide range of applications. They are used for manufacturing objects which we use daily such as parts of planes, cars and some other kind of objects. The cnc machine are also more precise, which allows them to create extremely detailed molds and patterns that might be impossible otherwise.

The method in which a Vedette CNC machine works is it takes a design or blueprint that has been made, and then the computer inside of it reads a computer program to guide what could be something such as a cutting tool through the material. In other words, it is a cutting tool (drill, router or laser cutter) that will be used for removing some material from the plate to produce an object required. Computer is used for the tack of making very precise edges to the maching, for example shape breaker or circles, as required by machine. Structure of all product a are designed for such size and situation. The best thing they can do this over and over again — with NO mistakes — so that everything they produce is the same as what was produced before. This consistency is critical in manufacturing.

Its Machinery - It's a cool place to be around all the machines and Vedette CNCs have potential to reinvent how things are manufactured. They automate manual tasks that were previously dealt with by humans in a complex manner. It enables them to produce faster and better products, producing less material waste. A factory might also mould one by hand in something like a day, compared to just a couple of hours with the help of cnc machines. The industry is a budding area for growth and development, but companies such as vedette are on the edge of these new age cnc technologies to help business progress in this ever so competitive market. Both businesses can benefit from reduced prices and consumers get better goods, but this is where the wave of technology revolution should bring?

To realize the full potential of these CNC machines in a business, it is necessary to know how to properly deploy them. Which also describes the operation with a utilised of the equipment, not just regarding how the machines functionality. You also need to make sure your employees are trained and know how to use the equipment safely and efficiently. Vedette is among the companies training these machines to save time in manufacturing parts — reducing waste and modeling high-quality slivers of metal or plastic into customer essentials. In order to make the most of CNC technology, nothing is more important than experience and/or education.

These CNC machines offer companies the advantage of working faster and with better performance. These machines can even perform some necessary tasks far faster and cheaper in businesses to deliver high-quality products. This added efficiency allows companies to focus on other essential aspects of their business. The single Best way to maximise CNC technology is essentially for companies to put their money where there mouth is -any profits earned -(keep your money) by buying and using the latest and most powerful range of machine cnc. It is very important to keep up with the technologies you are using. One of such some business enterprise is Vedette which provide the latest in CNC technology to help businesses clear a path for advancement and to increase income on production costs.

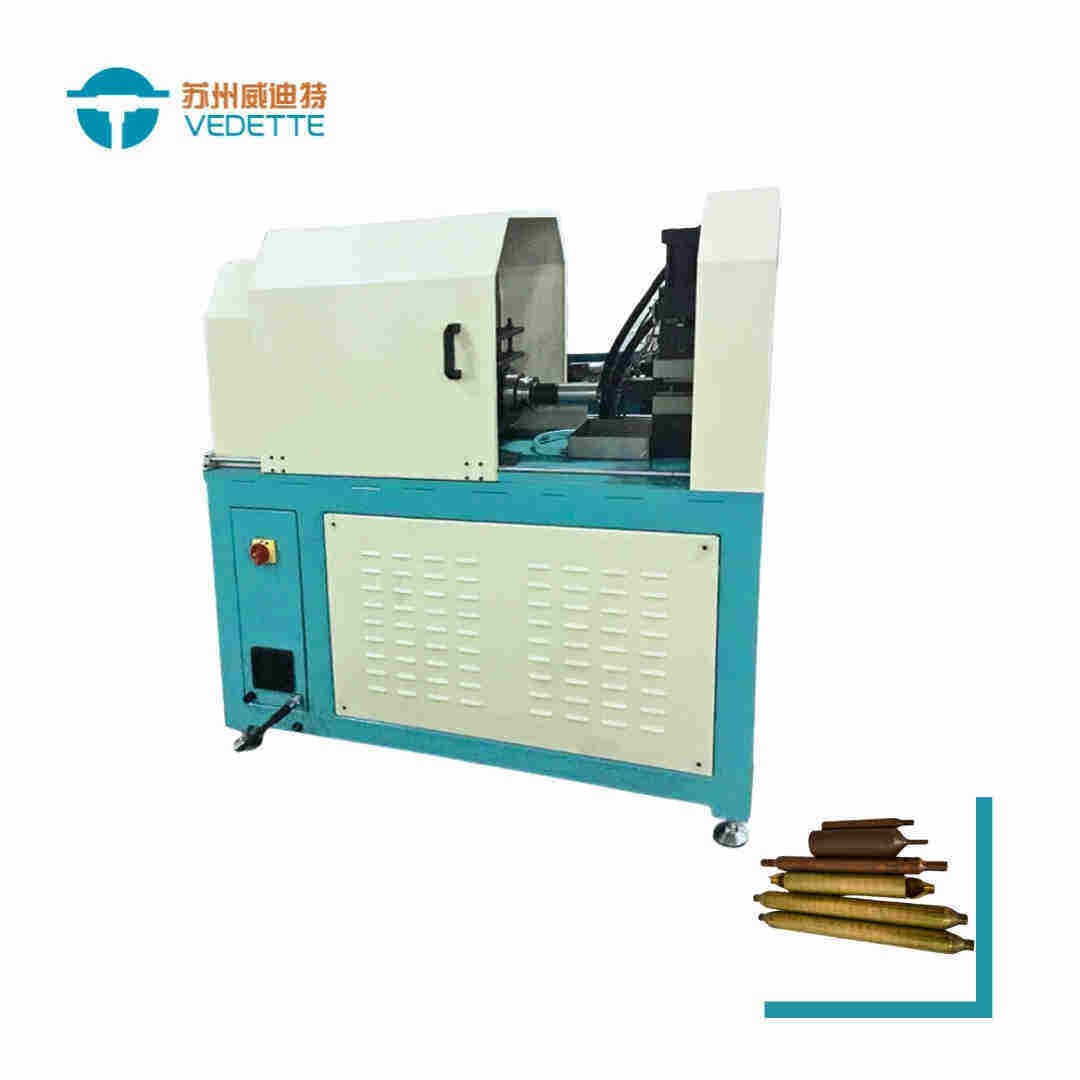

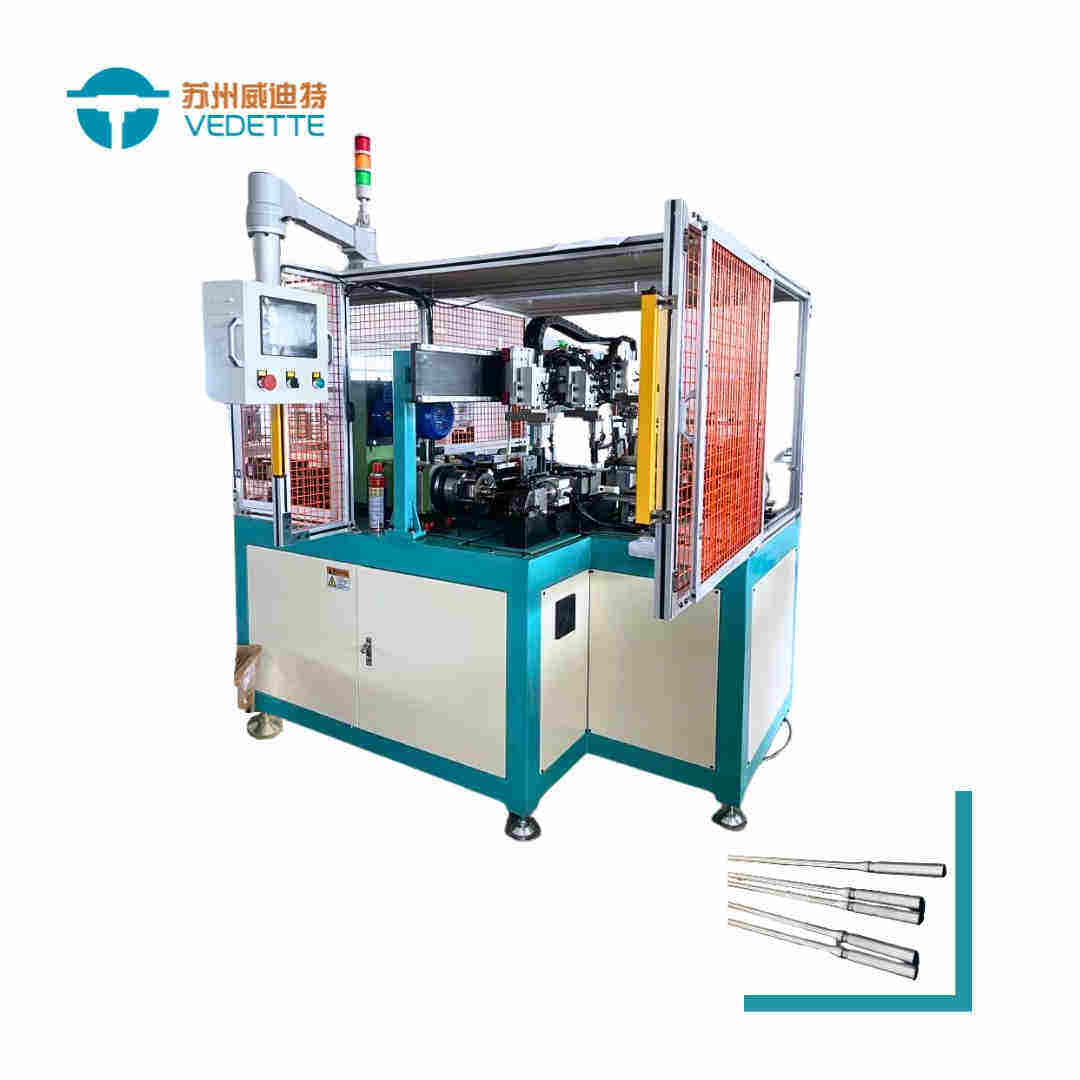

We are your Cnc machine machine for equipment to process pipes offering a variety of equipment to fulfill your needs. We have been working on the field of automation equipment for pipe processing for over 10 years and are able to offer more than 1000 non-standard design patterns. After a thorough understanding of the customer's needs the experienced sales staff will tailor services. The planning process for projects is followed to manufacture and debug our equipment. The process of assembly and debugging can be viewed online by the customer at any point. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to make sure that the equipment is quickly integrated into the client's factory production processes. We have a flawless record of equipment and data. The information of the customer's equipment is preserved both in documents and in paper. Mold updating is a way to provide drawings or Customization. After-sales support is provided by our expert team.

Suzhou Vedette Industrial Equipment Co., Ltd., founded in 2011, is located in Cnc machine machine located near Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a technologically advanced national company with more than 10 years of experience in research, development, manufacturing, and customizing automation production lines. In December 2022, it held 31 utility model and 10 patents on inventions of equipment. The equipment is popular both domestically and internationally, with customers from all over world. The company abides by its mission to provide valuable products and services for its customers, and is committed to being a leader in the development of technological innovations for tube processing equipment in China.

To ensure consistency and excellence in the quality of our products, we Cnc machine machine to the concept of quality first as well as take other steps such as source control, monitoring the production process as well as continuous improvement. We will keep adhering to this principle in the near future, and will continue to improve our services and products to offer greater value to our customers.

Cnc machine machine, as a top pipe processing equipment manufacturer in the field, places great importance to technological innovation and research and development investment and continues to introduce new products with market competitiveness in order to meet the changing needs of the market. We are committed to provide you with expert services, including pre-sales consultation and sales technical support and after-sales support. This will ensure that customers receive prompt and reliable solutions. Our products are highly applicable to a variety of industries. If you are a user who requires pipe processing equipment Suzhou VEDETTE is a reliable best choice.