Vedette does what so many other companies do and uses CNC machines to create all kinds of things from plastics. There are many advantages of Vedette CNC spinning machine over conventional methods for making things. One of the best features about them is that they can produce extremely complex shapes which are very difficult if not entirely impossible to create by hand. Therefore, designers are able to create new kinds of things even the creating was too troublesome for before.

CNC machines also help make production go faster. They are able to produce items at a speed much faster than traditional means and hence companies can create more products in lesser time. Besides, Vedette CNC spinning machine minimize the use of materials which helps to reduce waste. This is environmentally friendly and can save companies money.

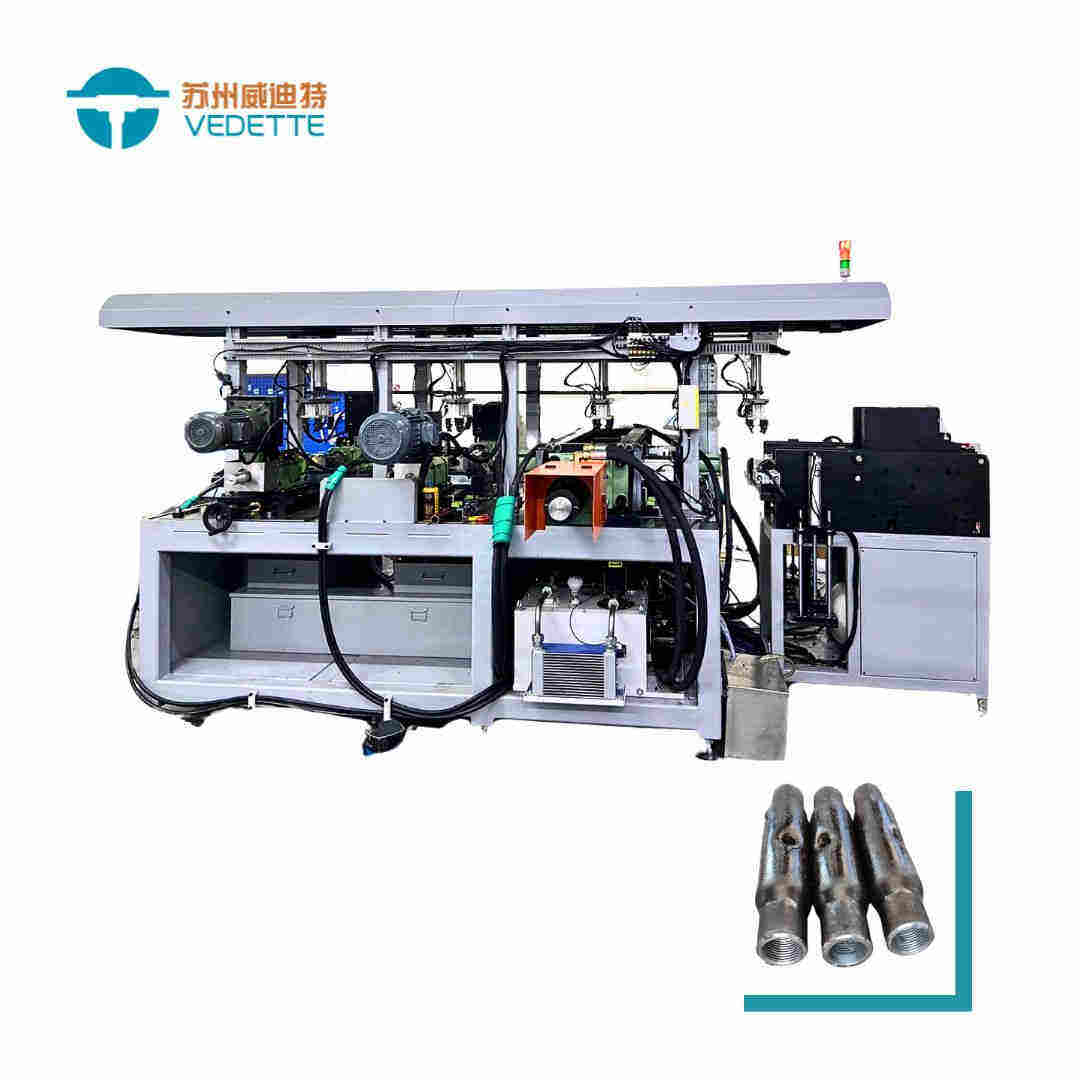

One of the most interesting things of Vedette 13 CNC pipe bender is how they are modifying products designed. In the past, it was not possible to produce complex-shaped and modeled objects. Now-a-days designers can start making new complex shapes of parts. Now, the gates of creativity and innovation have changed.

Instead of spending weeks, or even months, crafting a physical model by hand, designers can also make use of computer programmers to generate an electronic version. You can take this digital model directly to the Vedette 13 CNC pipe bender and create a tangible item. It not only streamlines the entire process, but makes it more convenient for designers to make revisions or changes. They can iterate more quickly to better design in a less amount of time.

CNC machines are also getting a lot easier to come by and cheaper. As a result, now this great technology can be utilized even by smaller companies, or individual. In conclusion, such Vedette 20 CNC pipe benders have revolutionized the way we understand and work on engineering products. It will be awesome to learn the new era processes of the world of CNC machining.

Suzhou VEDETTE, as a Cnc manufacturer of pipe processing equipment in the market, puts an immense importance to technological advancement and research and development investment and is constantly launching new products with market competitiveness to meet the ever-changing demands of the market. We are committed to quality of life, customer experience as our main goal, to provide you with a full range of professional services including pre-sales support as well as sales technical support after-sales support, to make sure that customers have access to of prompt and efficient technical assistance and solutions. Our products offer a broad application to meet the demands of different industries in pipe processing. For the users who need pipe processing equipment Suzhou VEDETTE is an ideal choice.

Cnc will always keep quality of our products as the mainstay by ensuring that we control the source manufacturing process monitoring, source control constant improvement, among other things in order to guarantee the high-quality and durability of the product. We will continue to adhere this principle in the future and continue to improve our products and services in order to provide greater value to customers.

Cnc was founded in 2011 and is located close to the gorgeous Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the production of equipment. With more than a decade of expertise in the development, research and production of tube processing equipment and various kinds of custom automation production lines that are a national high-tech company that is involved in the development and production of technologically automated and intelligent equipment. As in December 2022 it has 31 utility model patents, and 10 equipment invention patents. The equipment is well-received both domestically and internationally, with clients across the world. The company abides by its corporate goal of offering valuable products and services for its customers and is dedicated to being a leader in the field of technological advancement for tube processing equipment in China.

Our company is manufacturing pipe processing automation equipment for more than 10 year and we have over 1,000 design schemes that are not standard. Cnc sales teams can customize services based on a thorough understanding of customer demands. The process of planning the project is followed to manufacture and test our equipment. Customers can follow the equipment's construction and debugging progress on the internet anytime. They will conduct an exit inspection following the strict process for delivering the exit after the equipment has been accepted to ensure the equipment can be quickly integrated into the factory production processes of the customer. We have an archive system for data and equipment system that is flawless. The customer's data equipment is saved both in the form of paper and electronic files. The mold updating service could be used to provide drawings or Customization. After-sales assistance is provided by our expert team.