Today we are going to talk about big machines helpful in factories, and one of those machines is the stainless steel pipe double head chamfering machine. Stainless steel pipes are smooth edge making machine. A chamfering machine by Vedette is excellent; it works quite well and requires very few fixes over time.

A process known as chamfering, where you cut the edge of a pipe to a slant or angle. This makes pipes fit better and get a tighter fit when connected. Pipe chamfering of stainless steel pipe is extremely important. If the pipes are not aligned, they can leak, which can lead to issues in factories and buildings.

Designed to flawlessly edge each time, the Vedette-thé chamfering machine. It has heavy duty, high-quality blades to cut through the pipes at the correct angle. The goal is that when the pipes are assembled, everything mesh es together tightly without leaking or leaving gaps so that everything behaves as expected.

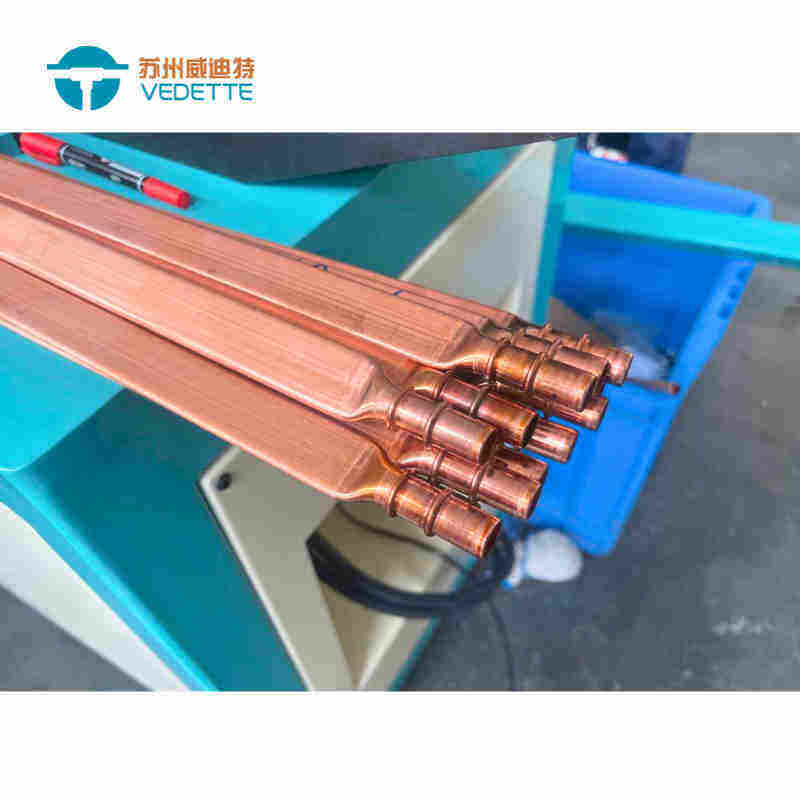

Dear reader, there is something very cool about that Vedette chamfering machine: it has two cutting heads. This allows it to process two pipes simultaneously which is useful. The ability to chamfer two pipes together is a real time saver and allows greater productivity with fewer operators.

It also makes the cuts more accurate and precise. Both heads cooperate to form smooth edges on either side of the pipe. This matters a lot in many factories and in industrial jobs where pipes must be made to fit snugly together. A minor error can cause serious difficulties down the road.

This machine is made of durable materials, and its blades are designed to have a long lifespan. The structures are highly reliable and allow for frequent usage with minimal reconditioning. The machines receives regular maintenance, with its easy-to-clean and replace parts system which minimizes machine downtime to ensure continued proper working status.

For large factories and industrial environments, the Vedette chamfering machine is excellent. It's capable of processing large diameter pipe and does so fast, which makes it extremely useful in manufacturing plants, construction jobs and other places where stainless steel piping is used.

To ensure consistency and excellence in product quality To ensure quality and stability in our products, we follow the premise of quality first and then take additional measures such as control of the source controlling the production process as well as continuous improvement. We will keep adhering to the quality-first principle in the future and improve our products and services to deliver Stainless Steel pipe double head chamfering machine to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. With more than a decade of expertise in the development, research and production of tube processing equipment as well as different types of custom-designed production lines for automation, it is a national high-tech company that is involved in the development and production of automated, technological, and sophisticated equipment. As in December 2022 it had 31 utility model patents and 10 patents for inventions of equipment. Its equipment is well-received domestically and internationally, with clients across the world. The Stainless Steel pipe double head chamfering machine is committed to its core mission of providing valuable products and services for its customers, and is committed to become a leader in the development of technological innovations for tube processing equipment in China.

Stainless Steel pipe double head chamfering machine company is manufacturing pipe processing automation equipment for more than 10 year and we have more than 1,000 designs that are not conventional. Once we have a complete understanding of the requirements of our clients and requirements, our experienced sales team can tailor the services to meet your needs. The project planning process is followed to manufacture and debug our equipment. Customers can watch the equipment assembly and debugging progress online anytime. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to ensure that the equipment is promptly incorporated into the customer's factory production tasks; We have a perfect data and equipment archiving system. The customer's equipment is preserved both in electronic and paper files. Mold updating can provide illustrations or Customization. After-sales support is provided by our experienced team.

Suzhou VEDETTE is a leading producer of pipe processing equipment for the field. It is a Stainless Steel pipe double head chamfering machine on research and development, and also launches new products that are competitive to meet the ever-changing needs of the marketplace. We place quality of life and customer experience as our main goal, to provide you with the full spectrum of professional solutions that cover pre-sales advice as well as sales technical support after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products cover a wide variety of application options for the requirements of various industries that require pipe processing. Suzhou VEDETTE, a leading manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.