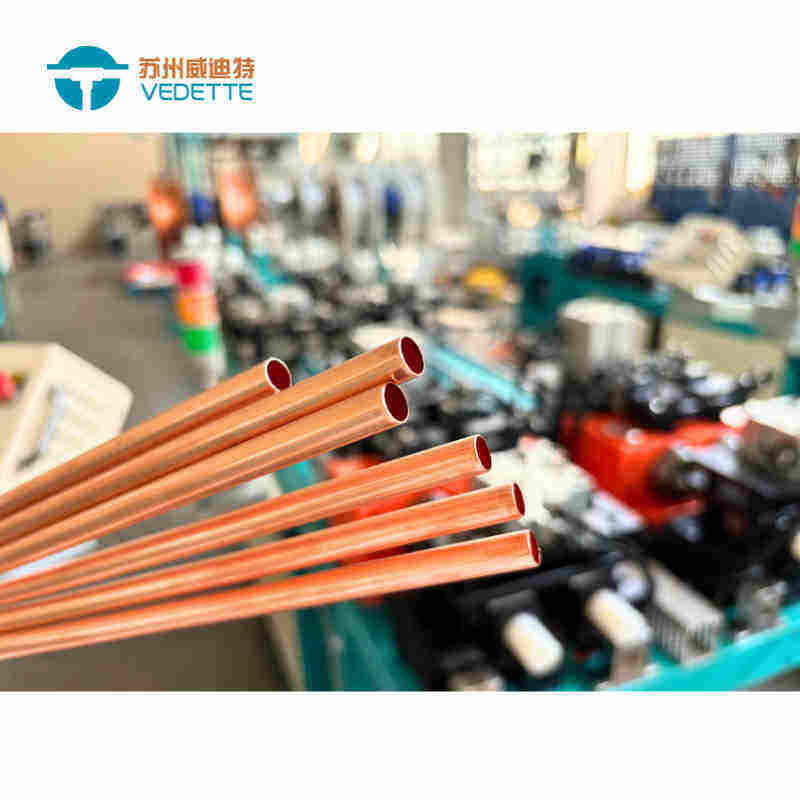

This is a type of machine, which is called as Aluminum Tube Cutting Machine; used commonly nowadays for getting faster production with precision in cutting aluminum tubes. What sets this apart is that it doesnt make a mess of cutting the tubes, or creating small pieces (which are commonly referred to as chips) that have to be cleaned up. It is so important for people who work in factories and produce things that need precise straight cuts. This machine makes it easier for workers to do their job by providing exact cuts when they need them. Being the material of aluminum tubes with a wide range of uses (aviation, automobiles, buildings,…), this machine has demonstrated its importance in the operation and usefulness in countless industries. Aluminum Tube Cutting Machine from Vedette can allow companies to bring efficiency in their working process and execute each task swiftly.

The Aluminum Tube Cutting Machine is very feature wise sophisticated but one thing is for sure that the machine has the best pieces cutting 99. On other cutting methods, small pieces can fall off and create a mess to clean up. These small pieces can be extremely difficult to clean and can really slow down the production process. This include means workers have to waste time cleaning up rather than making products. On the other hand, cutting through it and shaping can be a menace for even experience in steel processing to great deal amount of time and effort whereas Aluminum Tube Cutting Machine does one-shot clean cut saving a lot of valuable time. This is a massive boon for factories, as it means they can concentrate on producing new products as opposed to other issues after the cut has been made.

However, it can be very hard work to do this and can take a certain amount of time to manufacture products. Some machines cut through materials quite slowly which can be irritating for workers who just want to get on with the task at hand. But you can ease and speed up your work with Vedette's Aluminum Tube Cutting Machine. The new machine has been created to allow for the fast and precise cutting of aluminum tubes, enabling workers to produce more items in less time. Cutting faster means increased productivity in companies and let them make their goals on time. This is great to enhance workflow in any factory or manufacturing unit.

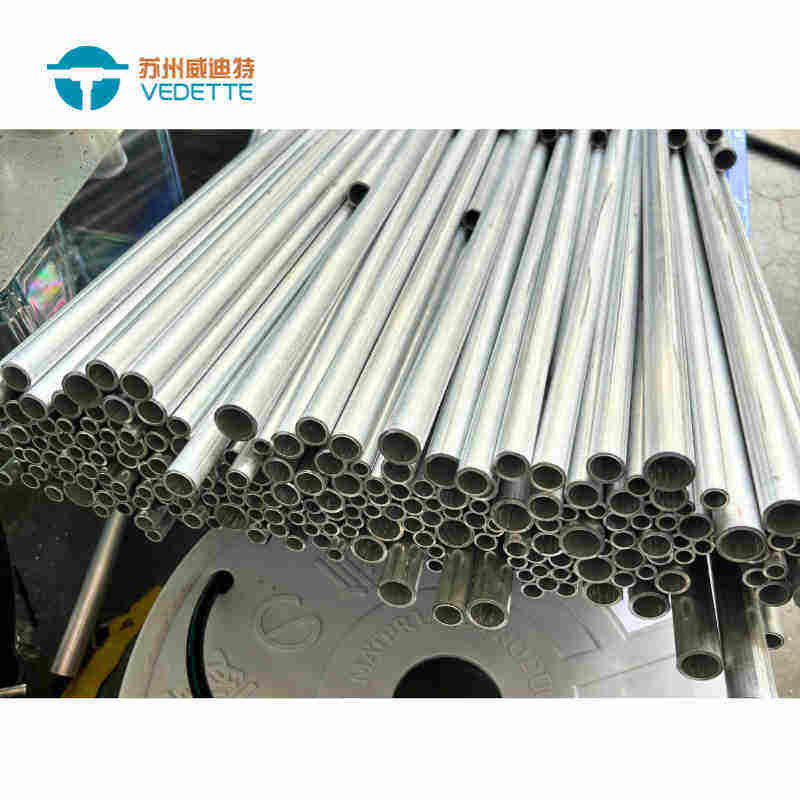

Aluminum Tube Cutting Machine is versatile and capable of handling most types of aluminum tubes. Thick or thin, this one can cut the tubes easily. It can also cut shapes in curves which comes in handy for various projects-- This machine offers a wide range of functionality which in return gives workers the power to do more in their work with ease. This agility is critical in manufacturing because it allows vendors to respond to distinct types of needs and demands respectively.

The Aluminum Tube Cutting Machine at Vedette comes with advanced technology to enable workers to be more productive. At the same time, it can cut fast, and then cut a large number of aluminum tubes with extreme precision. Its automatic feed function helps the machine produce a perfect cut each time, meaning less waste and more drive for overall productivity. It is being able to do more for all, because of how well machines work. This will allow workers to take pride in their work, while companies can produce larger numbers of products without the concern that an error will be made.

We are your Aluminum tube chip free cutting machine for equipment to process pipes offering a variety of equipment to fulfill your needs. We have been working on the field of automation equipment for pipe processing for over 10 years and are able to offer more than 1000 non-standard design patterns. After a thorough understanding of the customer's needs the experienced sales staff will tailor services. The planning process for projects is followed to manufacture and debug our equipment. The process of assembly and debugging can be viewed online by the customer at any point. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to make sure that the equipment is quickly integrated into the client's factory production processes. We have a flawless record of equipment and data. The information of the customer's equipment is preserved both in documents and in paper. Mold updating is a way to provide drawings or Customization. After-sales support is provided by our expert team.

Suzhou VEDETTE, as a leading Aluminum tube chip free cutting machine manufacturer in the market, puts the highest importance to technological innovation and investment in research and development, and continues to launch new products that compete to meet the increasingly diversified requirements of the market. We adhere to the quality of life, customer satisfaction as the primary objective and provide all the professional services covering pre-sales consulting, sales technical support, after-sales service, and ensuring that customers get the benefit of timely and professional technical assistance and solutions. Our products can be applied to a variety of industries. Suzhou VEDETTE which is a major manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.

To ensure consistency and excellence in product quality To ensure quality and stability in our products, we follow the premise of quality first and then take additional measures such as control of the source controlling the production process as well as continuous improvement. We will keep adhering to the quality-first principle in the future and improve our products and services to deliver Aluminum tube chip free cutting machine to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd., founded in 2011, is located in Aluminum tube chip free cutting machine located near Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a technologically advanced national company with more than 10 years of experience in research, development, manufacturing, and customizing automation production lines. In December 2022, it held 31 utility model and 10 patents on inventions of equipment. The equipment is popular both domestically and internationally, with customers from all over world. The company abides by its mission to provide valuable products and services for its customers, and is committed to being a leader in the development of technological innovations for tube processing equipment in China.