Aluminum tubes are found in a wide range of areas namely buildings, automobiles, and aeroplanes. Most of the crossbows are light, strong and do not rust easily. In order to cut aluminum tubes into the correct sizes and shapes, factories require specific machines known as aluminium tube punching and flanging equipment. The Vedette machine is one of the best there is. Specific manufacturers find this machine very useful as it perfectly cuts and shapes aluminum tubes.

This CNC punching and flanging machine can solve problems of improving the productivity in factories. This is a fast-paced machine, designed for speed, making time-saving and more output in factories. It also optimizes materials so that there is less waste. This matters, because it aids in keeping costs low. Having the ability to control your machine is a huge plus. It is this factory computer control that permits factories to produce huge amounts of identical-size and shape aluminum tubes. When products are made through common processes, factories can get their items to customers a lot faster.

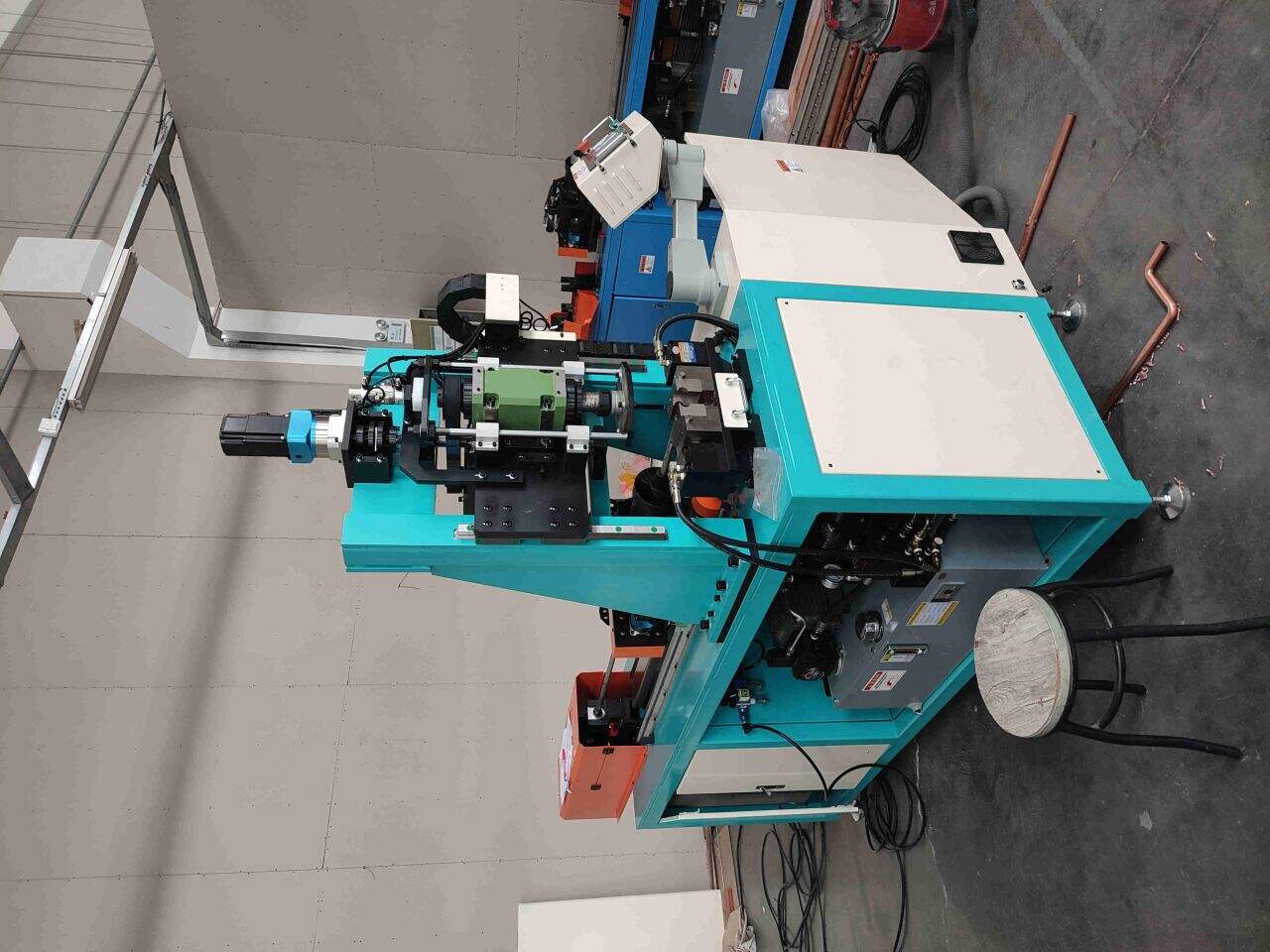

Vedette's machine is quite multi-purpose, which means it can perform many different jobs on aluminum tubes. It can, for example, punch holes in tubes as well as flanges and roll the edges. This versatility is significant as it can allow factories to produce different types of aluminum tubes for a wide range of uses. It can also do various jobs simultaneously. This is great for manufacturers that need to produce mass quantities of tubes quickly and cost-effectively. It was time-efficient and increased productivity when a single machine can perform multiple tasks simultaneously.

The fact that thenarrVedette machine is black and fat is one of the advantageous aspects of its functionality. It reads No. 2, which makes it durable enough for a lot of use without deteriorating. Factories have long working hours; a reliable machine is crucial.” The unit is built with well-made components that lead to longevity in use. Since it is based on a computer, the operation has less error than human-operated machines. The machine will be out of service when the downtime occurs, so this is extremely beneficial as it minimizes downtime. The less downtime that a factory has, the more money they can save on repairs and continue their production smoothly.

Summary: The Vedette aluminum tube punching and flanging machine are perfect for those factories which try to work in a productive way and also save time! The computerized controls ensure accurate and consistent production of the aluminum tubes, essential for maintaining quality. This versatility, strength and reliability make this investment well worth it for any manufacturing business.

We are the one-stop supplier for pipe processing equipment providing a range of equipment to meet your needs. We have been working on the area of automation equipment for pipe processing since more than 10 years and are able to offer more than 1,000 design concepts that are not standard. Expertly-trained sales teams can customize solutions based on an in-depth understanding of customer needs. Our equipment is produced and disassembled according to the project plan. Customers are able to monitor the equipment's assembly and debugging process online anytime. They will conduct an exit inspection following the strict exit delivery procedure once the equipment is accepted so that the equipment can be Aluminum tube punching and flanging machine in the factory manufacturing tasks of the client. We have an equipment and data archive system that is perfect. The information of the customer's equipment is stored both in documents and in paper. The mold updating service can be used to create drawings or Customization. We have a highly skilled after-sales team that provides after-sales cleaning and maintenance.

Aluminum tube punching and flanging machine ensure the highest quality and stability in the quality of our products We adhere to the principle of quality first as well as take other steps such as source control as well as monitoring the process of production, and continual improvement. In the future, we will continue to keep to the principle of quality first. We will continue to improve the level of products and services to bring more value to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is located in the southwest of Suzhou, near the Aluminum tube punching and flanging machine, an innovation center in the manufacturing of Aluminum tube punching and flanging machine. It is a high-tech company that has more than 10 years of experience in research development, manufacturing and modifying automation production lines. At the time of its December 2022 launch, it had 31 utility model and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, with clients across the world. The company abides by its core mission of providing high-quality products and services to customers, and is committed to being a leader in the field of technological advancement for tube processing equipment in China.

Suzhou VEDETTE, as a leading Aluminum tube punching and flanging machine manufacturer in the market, puts the highest importance to technological innovation and investment in research and development, and continues to launch new products that compete to meet the increasingly diversified requirements of the market. We adhere to the quality of life, customer satisfaction as the primary objective and provide all the professional services covering pre-sales consulting, sales technical support, after-sales service, and ensuring that customers get the benefit of timely and professional technical assistance and solutions. Our products can be applied to a variety of industries. Suzhou VEDETTE which is a major manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.