It is an special and helpful tool of the plumbers to bend the pipes by using semi automatic pipe bending machine. This machine allows you to bend pipes way easier and faster than by hand. It is ideal for those people who want to get their plumbing work done without spending so much time and feeling so tired. This machine uses motors to bend the pipe. They do not involve any input from the operator, they simply choose what angle and shape of bend they require and then the machine takes care of the rest.

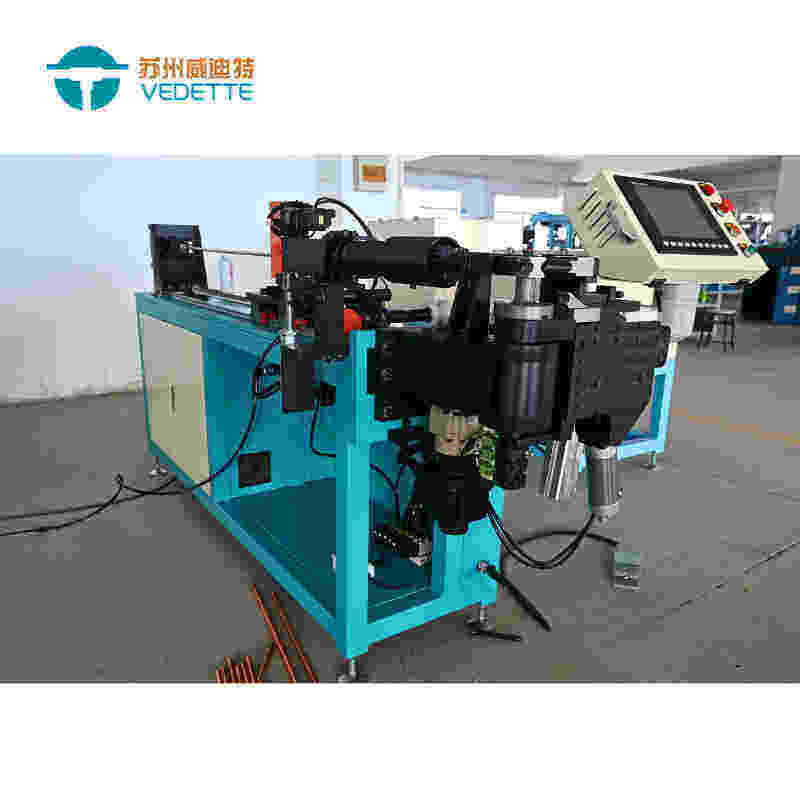

Vedette tube punching equipment is designed to make pipe bending easy and efficient for plumbers. So they run it through with a big, strong hydraulic motor to bend the pipes 180 degrees — a HUGE TURN! This means that plumbers can make sharp bends or gentle curves as they need. capable of working with various pipe sizes and shapes, the machine is an asset to any size plumbing work. Whether the pipe is thick or thin, straight or curved, this machine bends it just right.

The Vedette pipe bending machine is equipped with very smart capabilities. This means it can vary the angle and the shape of the bend depending on the width of the pipe. With this smart technology, every bend is precise and aesthetically pleasing. When plumbers are using this machine, they can always be sure that the bends will be perfect. This enables them to do their work effectively and bring about a professional look in performing their tasks.

Speed is crucial when it comes to plumbing projects. “We have the highest number of tickets to do per day,” adds the plumbers. However, if you want to get through your work quickly, Vedette's semi-automatic machine is your best friend. It takes just a few minutes to bend a pipe using this machine, which saves plumbers a ton of time. The machine moves so quickly, it enables plumbers to finish more jobs in less time. So busy plumbers who want to maximize productivity will find this feature of great usefulness.

The other wonderful thing about the semi-automatic machine from Vedette is it is very easy in use. Even with zero plumbing knowledge, one can figure out how the machine works in no time. Thanks to the straightforward design and clear instructions, anyone can begin bending pipes immediately. So, both expert plumbers and newbies will not have any issues using the machine. Given enough practice, they can become experts at pipe bending overnight.

We are your single-stop source for equipment to process pipes, offering a range of machines to fulfill your needs. We are semi-automatic pipe bending machine on the field of automation for pipe processing equipment for over 10 years and have nearly 1,000 design concepts that are not standard. Sales professionals with experience can tailor services after detailed understanding of customer demands. Our equipment is designed and debugged according to the project schedule. Customers can watch the equipment assembly and debugging progress online anytime. When the equipment is approved and inspected, they'll carry out exit Inspection in strict accordance to the exit delivery procedure to ensure that the equipment will be promptly incorporated into the customer's factory production tasks; We have a perfect storage system for data and equipment. The data of the equipment used by customers is stored in paper files as well as electronic files. Mold updating will provide sketches or custom. We have a highly skilled service department after sales and can provide after-sales cleaning, maintenance and cleaning.

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the semi-automatic pipe bending machine. It puts a lot of emphasis on technological innovation, research as well as development, and has launched new products that are competitive in keeping up with the changing needs of the market. We place quality of life, as well as the customer experience as the core of our business, and offer the full spectrum of professional services that include pre-sales consultation and technical support for sales, after-sales support, to make sure that customers get the benefit of professional and timely technical support and solutions. Our products have a wide selection of applications to meet the needs of different industries in pipe processing. Suzhou VEDETTE, a leading manufacturer of equipment for pipe processing is the best option for users.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. With more than a decade of expertise in the development, research and production of tube processing equipment as well as different types of custom-designed production lines for automation, it is a national high-tech company that is involved in the development and production of automated, technological, and sophisticated equipment. As in December 2022 it had 31 utility model patents and 10 patents for inventions of equipment. Its equipment is well-received domestically and internationally, with clients across the world. The semi-automatic pipe bending machine is committed to its core mission of providing valuable products and services for its customers, and is committed to become a leader in the development of technological innovations for tube processing equipment in China.

To ensure stability and quality in the semi-automatic pipe bending machine of our products We adhere to the premise of quality first and implement other measures such as control of the source as well as monitoring the process of production and continuous improvement. In the future we will continue to keep to the principle of quality first. We will continue to enhance the quality of our products and services to create greater value for customers.