CNC machines are fantastic tools and they have transformed the way items are made. Back in the olden days, people made things by hand (laborious task and time-consuming). They resided in the area where they had to measure and cut resources in order to operate, so there is always a margin of error. With CNC machines, we can make stuff faster and more precise than ever, the same as Vedette's copper pipe cutting machine. This allows us to create decent products in a minimal amount of time and effort.

Contrary to this, computer numerical control (CNC) machining is a unique manufacturing process that utilizes an automated device with input from a computer system in order to shape material through the removal of unwanted parts and subsequently turn it into a finished item, similar to the soft copper pipe bender from Vedette. This allows the factories to build very intricate parts with exacting accuracy. This technology makes it possible to manufacture things we never could make before. We can create complex shapes and designs that would be impossible to do manually for example. The computer can now follow custom commands to mold every single piece perfect.

One of the biggest advantages of using CNC machines is that they can operate without human intervention at times, the same as Vedette's copper pipe bending machine. This allows the machines to run 24/7, so you can consistently produced parts quickly. A person needs to rest and take breaks while a CNC machine never stops. For factories, it makes easy to produce a tons more of items in no time Moreover, the CNC machines are able to form parts with a detail level unattainable by people. It may be a small thing, but this level of accuracy was necessary in lots of industries (think automotive or aerospace, where every bit needs to go together perfectly).

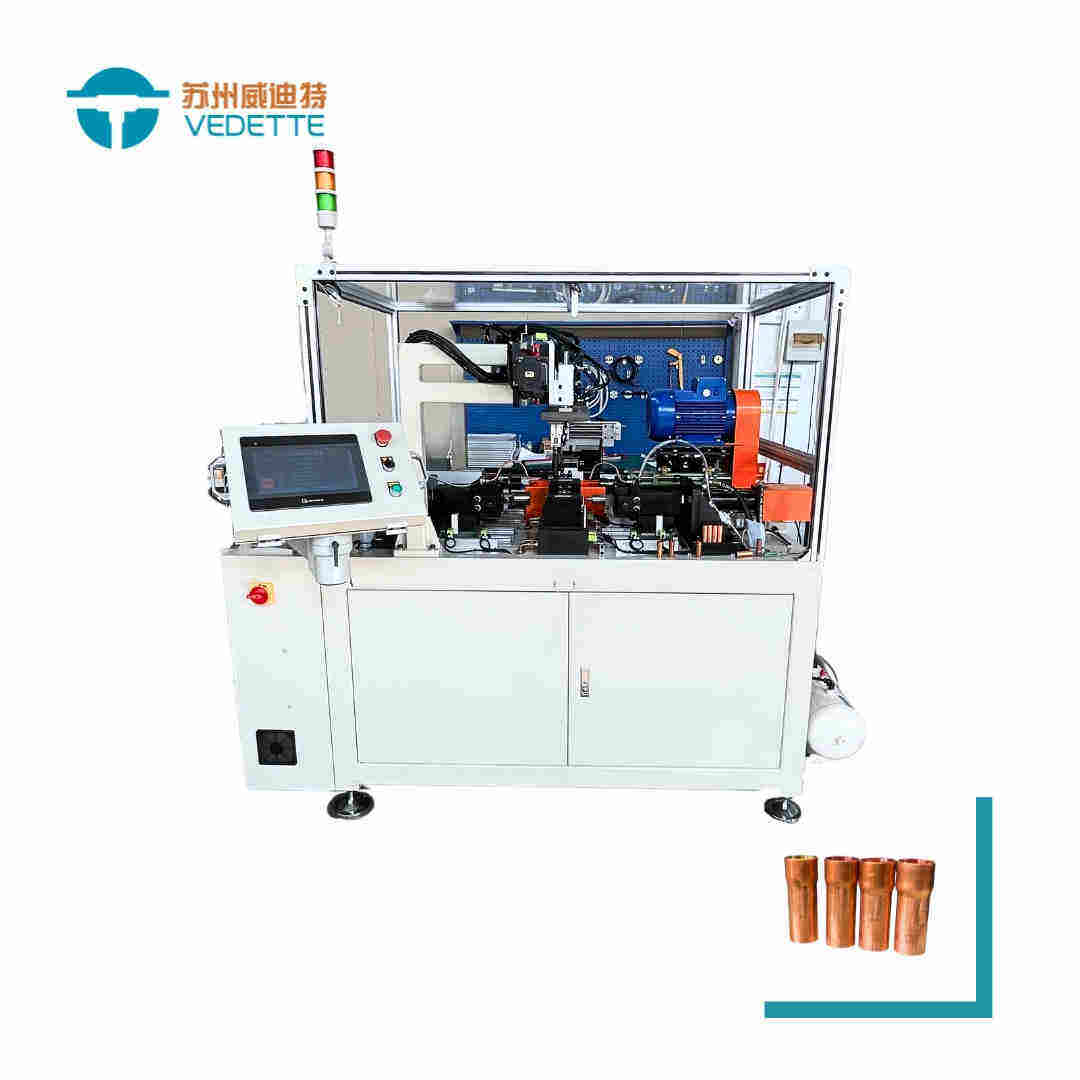

For many reasons, CNC machines are deployed all over in factories, also the pipe chamfering from Vedette. This means that parts are produced faster and more precisely than ever, which is crucial when you have a high demand. Now, in order to have satisfactory outputs from CNC machines, there is a need to utilise proper tools and technologies. Businesses such as Vedette have developed tools specifically trained to aid CNC machines in performing much more efficiently. Because of these sophisticated tools, which have paved the way for faster, cheaper and higher quality part production. Simply put, it is saving manufacturers money and allowing them to produce the modern marvels we see today in half the time.

CNC Machines have also enabled the creation of so many things, identical to Vedette's product stainless steel pipe cutter machine. We can now create extremely complex shapes and designs that were more difficult before because of the machine being controlled by a computer. This is very exciting for designers and engineers so. The evolution of automation has not only meant faster, more accurate production, but also the increase in speed and reliability of manufacturing parts. The technology enables manufacturers to explore original design possibilities and materials, which can open future doors for manufacturing. You can explore with colors, shapes or sizes and you can screw up big time.

Our company has been manufacturing pipeline processing automation equipment for more than 10 year and we have over 1000 designs that are not typical. Experienced sales projects will customize services based on a thorough understanding of the needs of customers. Our equipment is designed and tested according to the project design process. Customers can follow the equipment's assembly and debugging process online anytime. When the equipment is approved, they will carry out the inspection of exit in line with the process of exit delivery to ensure that the equipment can be swiftly integrated into the customer's factory production processes. We have a flawless storage system for data and equipment. All Cnc machine about equipment and customers are preserved in paper files and electronic files. The mold updating service could be used to draw sketches or custom. After-sales assistance is provided by our team of experts.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is located in the southwest of Suzhou, near the Cnc machine, an innovation center in the manufacturing of Cnc machine. It is a high-tech company that has more than 10 years of experience in research development, manufacturing and modifying automation production lines. At the time of its December 2022 launch, it had 31 utility model and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, with clients across the world. The company abides by its core mission of providing high-quality products and services to customers, and is committed to being a leader in the field of technological advancement for tube processing equipment in China.

We Cnc machine adhere to the quality as the core by ensuring that we control the source, production process monitoring and continuous improvement as well as other methods, to ensure the excellence and reliability of the product. We will keep adhering to the quality-first principle into the future and improve our products and services in order to offer greater value to our customers.

Suzhou VEDETTE is a leading Cnc machine of pipe processing equipment in the field. It places great emphasis on technological innovation, research as well as development, and has launched new products that are competitive to meet the ever-changing demands of the market. We're committed to provide you with expert solutions that include pre-sales consulting as well as sales technical assistance and after-sales support. This ensures that our customers get prompt and efficient solutions. Our products are broadly applicable to different industries. Suzhou VEDETTE which is a major manufacturer of equipment for pipe processing is the best choice for users.