Pipe is a primary component in most plumbing processes as well as for constructing other things and therefore, the necessity to make straight and precise cuts when working with pipe. Making these cuts accurately is the intended to help the pipes fit together well and reduce water or other materials from leaking out. A super handy tool for doing that is a piping cutter

A pipe cutter is a specific tool (designed for cutting pipes properly and cleanly) The best application of this tool is when you wish to cut round pipes. A pipe cutter can also be adjusted so that you can use it on multiple sizes of soft copper pipe bender which is really cool. That said, it makes an extremely convenient all-purpose tool for many projects.

And, if you are a beginner in using piping cutter then, it would be highly recommended that you should spend some time understanding the operation of this tool. Getting acquainted with the tool will make you more confident. To help you, here are some tips adhered to the framework

Just take your sweet time and be really slow with this process. I do not rush those steps because then I would make mistakes, and as they do say back to the future to act on that: “If you put your mind to it, you can accomplish anything.”

What to use a chain cut for larger pipe cutting is also as important as knowing that it exists. This method involves a cutter that you manipulate via the use of a hand-crank. It works by having a chain that wraps around the best copper pipe bender being turned by a crank to cut it. This is especially true for thicker materials.

Each type of pipe is different, so each will need to be cut differently. For instance PVC pipes are very malleable and can be airily sectioned through with a customary piping cutter. Conversely, hard copper pipe bender are sturdier and require a more robust blade to create cuts which are clean.

Now, if you are someone who works with pipes — then pipe cutting tools would be the best thing that can happen to people. Whether you are a professional plumber or a DIY enthusiast who wants to know the best way to cut PVC pipe, it is very important for safety reasons to make perfect cuts using proper techniques. With a good couple of tools and knowledge you can not only finish the job but do so with confidence.

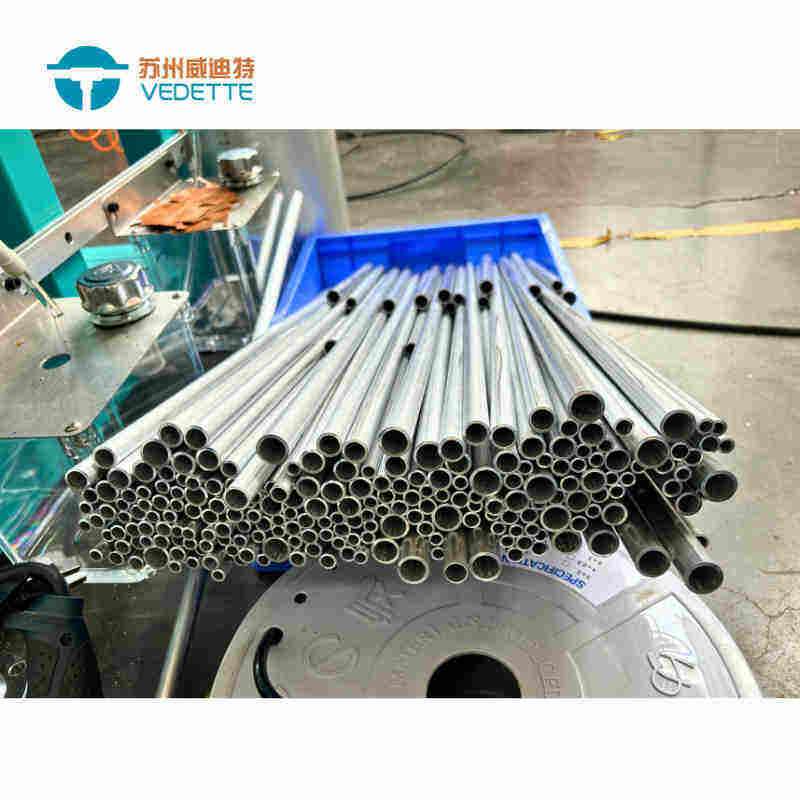

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an Piping cutting importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. With more than a decade of expertise in the development, research and production of tube processing equipment as well as different types of custom-designed production lines for automation, it is a national high-tech company that is involved in the development and production of automated, technological, and sophisticated equipment. As in December 2022 it had 31 utility model patents and 10 patents for inventions of equipment. Its equipment is well-received domestically and internationally, with clients across the world. The Piping cutting is committed to its core mission of providing valuable products and services for its customers, and is committed to become a leader in the development of technological innovations for tube processing equipment in China.

To ensure stability and quality in product quality We adhere to the principle of quality first, and take other measures like source control, Piping cutting the production process and constant improvement. In the future, we will continue to stick to the principles of quality first, constantly improve the level of products and services to bring more value to our customers.

We are your Piping cutting for equipment to process pipes offering a variety of equipment to fulfill your needs. We have been working on the field of automation equipment for pipe processing for over 10 years and are able to offer more than 1000 non-standard design patterns. After a thorough understanding of the customer's needs the experienced sales staff will tailor services. The planning process for projects is followed to manufacture and debug our equipment. The process of assembly and debugging can be viewed online by the customer at any point. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to make sure that the equipment is quickly integrated into the client's factory production processes. We have a flawless record of equipment and data. The information of the customer's equipment is preserved both in documents and in paper. Mold updating is a way to provide drawings or Customization. After-sales support is provided by our expert team.