Well, today I'm going to show you awesome machine — the pipe punching! What are you made of? Have you heard of this machine before? If you haven’t, that’s completely fine! I’m here to help you understand what it is, how it works and, more importantly, why it can be extremely beneficial to anybody who works with pipes.

Let’s say you are working on some huge project and you got tons of these pipes that all need those beads on them. You would practically have to cut all the pipes by hand if you did not have a pipe bead cutting machine. All you would have are tools — things like a saw or a grinder — to separate each bead, one by one. That seems like a lot of work that would take a very long time! Plus, doing it by hand, it can be prone to errors, in that it’s easy to cut the pipe the wrong way.

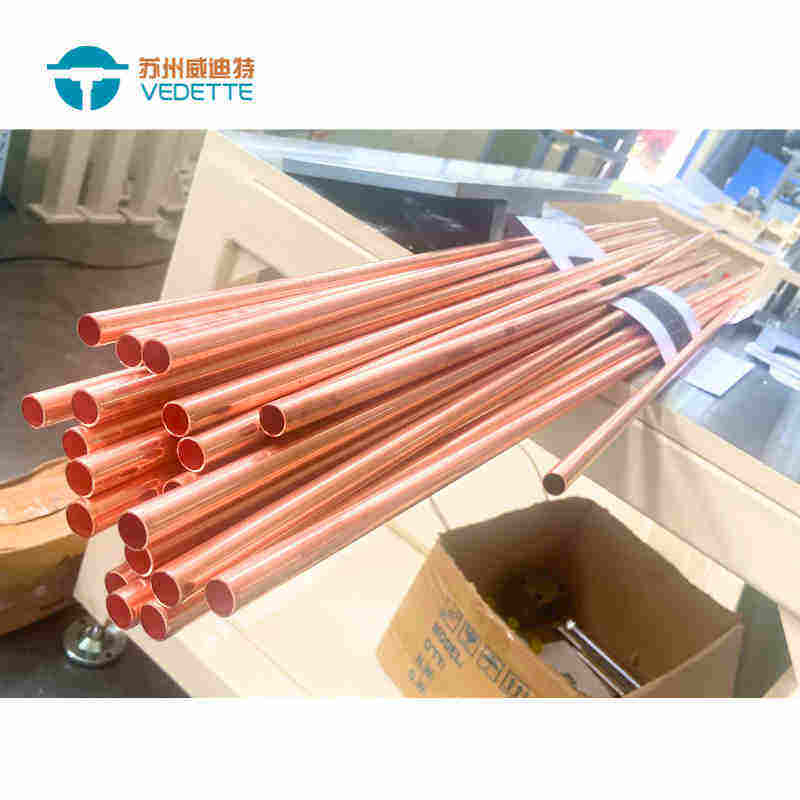

But guess what? To cut off those beads quickly and accurately, you need a pipe hole punching machine. That is, you save a ton of time and also, every single time the cuts are perfect, so you create better products! It’s a pretty versatile machine as well, as you can use them on pipes of various sizes and materials. Which makes it quite a handy tool for anyone who works with pipes.

We are always thinking of how to improve our machines more than ever at Vedette. Our new pipe bead cutting machines are faster and even more economical than ever. These devices are equipped with advanced cutting systems and easy-to-use controls. This means increased efficiency and shorter work times without sacrificing quality or safety.

Okay, next — let’s discuss safety, because that’s very important! For that reason, all of our machines are equipped with special safety features. They also have features like automatic shutoff, so the machine will turn itself off if there is a problem. There are emergency stop buttons that anyone can push if the machinery needs to be stopped immediately. These features also help ensure your work environment remains safe for all.

Speaking of safety, our machines are all about very safe, even cuts. So this is very crucial because if the cuts are not equal, it will lead to problems down the road. So you will always have a perfect cut every time as you can also set the machine to cut beads in the manner that you want it!

So, there you have it, kids! So, you are well aware of pipe bead cutting machine and how it can change the way you work for better. With the incredible machines from Vedette, you can save time and earn more money by creating quality products. And safety comes first, and be sure we're working with the newest technology to make your know workers safe.

pipe bead cutting machine ensure the highest quality and stability in the quality of our products We adhere to the principle of quality first as well as take other steps such as source control as well as monitoring the process of production, and continual improvement. In the future, we will continue to keep to the principle of quality first. We will continue to improve the level of products and services to bring more value to our customers.

We are the one-stop supplier for pipe processing equipment, offering a range of pipe bead cutting machine to satisfy your needs. We have been working on the field of automation equipment for pipe processing since more than 10 years, and have over 1,000 design concepts that are not standard. Our sales professionals are experienced and can tailor solutions based on an in-depth understanding of the needs of customers. Our equipment is designed and debugged according to the project plan. The process of assembly and debugging can be seen online by the customer at any time. Once the equipment is accepted by the customer, they'll conduct an the exit inspection in accordance with the process of exit delivery to ensure that the equipment can be promptly incorporated into the customer's factory production processes. We have an efficient data and equipment archiving system. The customer's data equipment is preserved both in documents and in paper. Mold updating can provide sketches or custom. We have a knowledgeable service department after sales and can provide after-sales cleaning and maintenance.

Suzhou Vedette Industrial Equipment Co., Ltd., founded in 2011, is located in pipe bead cutting machine located near Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a technologically advanced national company with more than 10 years of experience in research, development, manufacturing, and customizing automation production lines. In December 2022, it held 31 utility model and 10 patents on inventions of equipment. The equipment is popular both domestically and internationally, with customers from all over world. The company abides by its mission to provide valuable products and services for its customers, and is committed to being a leader in the development of technological innovations for tube processing equipment in China.

pipe bead cutting machine, as a top pipe processing equipment manufacturer in the field, places great importance to technological innovation and research and development investment and continues to introduce new products with market competitiveness in order to meet the changing needs of the market. We are committed to provide you with expert services, including pre-sales consultation and sales technical support and after-sales support. This will ensure that customers receive prompt and reliable solutions. Our products are highly applicable to a variety of industries. If you are a user who requires pipe processing equipment Suzhou VEDETTE is a reliable best choice.