An automatic chamfering machine is a particular category of machines which offer great assistance in rounding and smoothing the edges of different types of materials. The process of chamfering is nothing but smoothing the edges. Chamfering an edge is the process in which we dull it down a little to look better, and be less of a cut hazard. Vedette auto-chamfering machine being a case of such a solid and effective unit for the activity. This is specifically designed to not only make products appear good but also assures a high-quality finish.

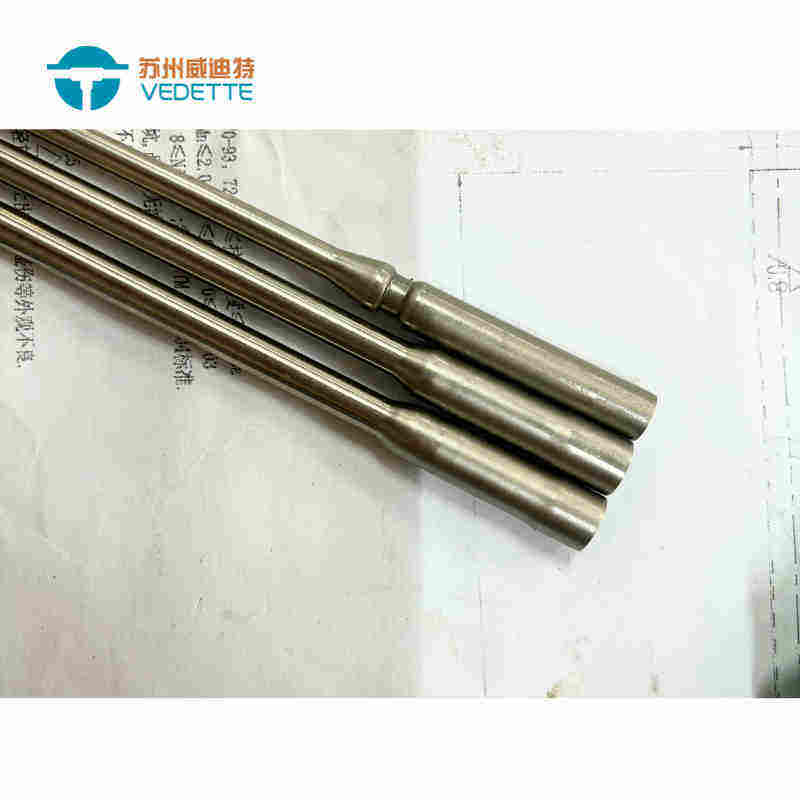

Here are chamfer is a critical process in many industrial and production facilities. Using an automatic chamfering machine will help you to save time and even effort and ensure that your products look incredible. Before, if chamfering had to be done manually, it could take a very long time in order for everything to end up perfect. However, with a pipe chamfering, you are able to make multiple in a matter of minutes. This translates to higher factory output and more efficient factories.

The automatic chamfering machine is also improving the quality of the products. It is able to make perfectly uniform straight edges. It is a good way for the product to appear serious, and this always reflects well on any business. The quality is kept to a high level regardless of who utilizes the machine. This is a huge plus as it enables keeping up the quality that customers yearn.

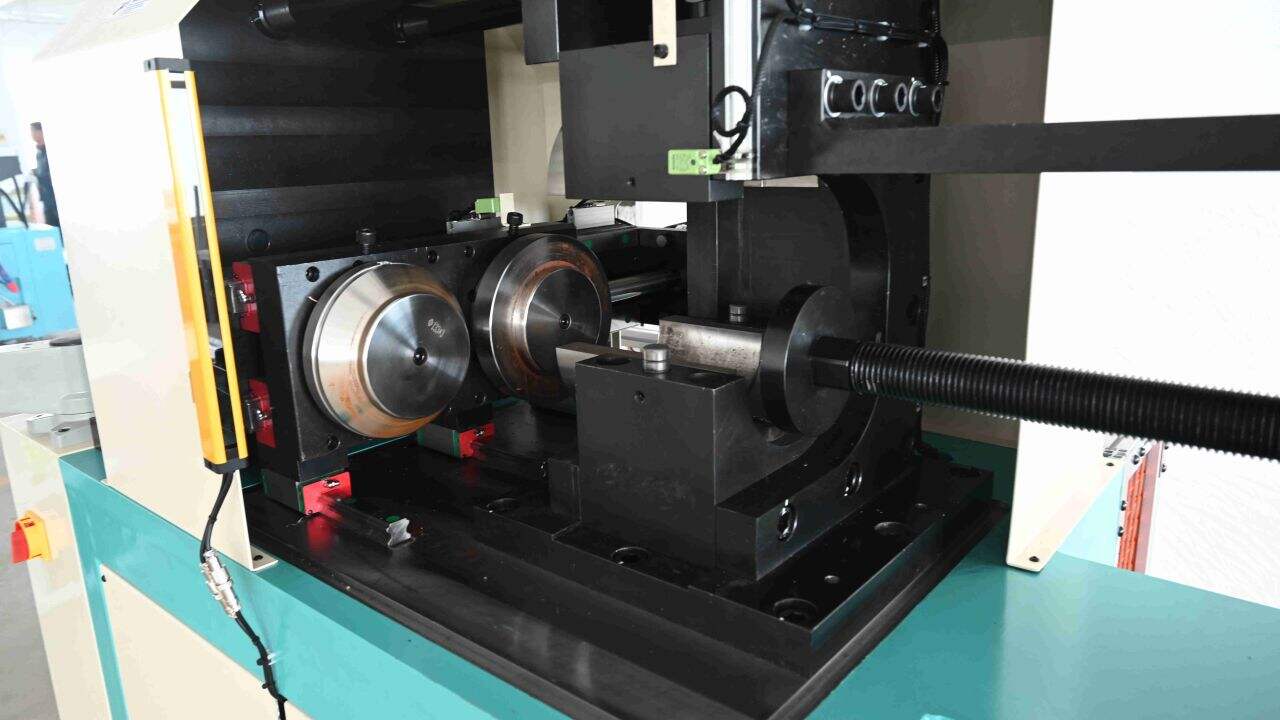

There are some main special parts in the automatic chamfering machine, and they will assist it to make a good performance. You can program or change the setup of the machine to do different types of chamfering depending on what you require for your products. Tools of chamfering machines are of different shapes and sizes making the device customizable according to requirement. The Vedette automatic chamfer machine, for example, is made easy to use so operators can set up the system without extensive training.

The automatic chamfering machine employs smart and advance technique to satisfy the same activity each time. This technology helps the machinery to give a precise and ideal finish for each product with which it is applied. The automatic chamfering machine is designed to ensure all the chamfered edges, irrespective of their size are equal in high quality. This consistency is critical in manufacturing and builds trust with customers.

The automatic chamfering machine can be of great help in saving you time and money. Sure, it may well cost you a little bit of money up front to buy the machine, but this in turn can actually help you make more products quicker and keep them all at an exceptional standard every time. Regarding large arvec producers, this would mean they will not need as many hands to the work and that it directly reflects in lower costs of labor. This Vedette tube chamfering machine saved time and money can go help you focus on different labour intensive job in the factory or in further new projects.

Suzhou VEDETTE is Automatic chamfering machine leading producer of pipe processing equipment in the field. It focuses heavily on technological innovation, research and development, and launches new products that compete to meet the ever-changing demands of the marketplace. We are committed to quality of life and customer experience as our main goal we provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance, to ensure that customers get the benefit of timely and professional technical assistance and solutions. Our products have a wide range of applicability to meet the requirements of various industries that require pipe processing. For the users who need pipe processing equipment Suzhou VEDETTE is definitely an excellent choice.

To ensure consistency and excellence in product quality To ensure quality and stability in our products, we follow the premise of quality first and then take additional measures such as control of the source controlling the production process as well as continuous improvement. We will keep adhering to the quality-first principle in the future and improve our products and services to deliver Automatic chamfering machine to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the manufacturing of equipment. With over a decade of expertise in the development, research and manufacturing of tube processing equipment as well as different types of custom-designed automation production lines, it is a national high-tech company that is involved in the design and manufacture of technologically automated and sophisticated equipment. As as of December 20, 2022, it had 31 utility model patents, and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, serving clients across the world. The company adheres to its corporate goal of offering quality products and services that add value to customers, and is committed to becoming a pioneer in the field of technological advancement for tube processing equipment within Automatic chamfering machine.

We are the one-stop supplier for equipment to process pipes providing a range of equipment to meet your needs. We are focusing on the field of pipe processing automation equipment since more than 10 years and are able to offer more than 1,000 non-standard design schemes. Experienced sales projects will customize services following a thorough analysis of customer demands. Our equipment is produced and developed according to the Automatic chamfering machine. The process of assembly and debugging can be seen online by customers at any time. They will conduct an exit inspection strictly in line with the process for delivering the exit once the equipment is accepted so that the equipment can be quickly integrated into the factory production tasks of the customer. We have an archive system for data and equipment system that is completely reliable. All equipment information of customers is preserved in paper files and electronic files. Mold updating can provide illustrations or Customization. After-sales services are provided by our professional team.