Another advantage is the precision of pipe CNC cut machines. They are able to make cuts that are miniscule, often within tenths of a millimeter. That precision guarantees that every piece is identical in size and shape. This degree of precision is essential if we are to manufacture high end products that are safe and function properly in diverse environments. With proper cuts, you can rest assured that your products will reach a certain level of safety, and offer reliability.

Pipe CNC cut machines are not only accurate but also very fast. They can chop way more pipes in a much shorter time than by hand. The quickness saves not only time but also helps save money since you can create more products in a shorter amount of time. Because you can quickly change your production schedule with these machines, you can tailor it to what you need. This freedom can be incredibly useful, particularly for changing demands or deadlines.

They usually help you work more efficiently and make fewer mistakes. Automating cutting not only eliminates the need for manual labor, which can result in fatigue among employees and a lack of consistency in quality.] As machines do not get tired unlike humans, this is why the quality of the products is guaranteed to be very good. This also frees up their time to focus on other important tasks like assembling or quality control on the end product.

One more way in which these machines proved useful was their flexibility. A significant advantage is that they can be programmed to cut pipes with different shapes and sizes. They can also manage a range of tasks from transporting tiny medical tubes to massive industrial pipes. It can even cut tricky shapes on an angled or curved surface easily. This versatility allows you to make a lot of different products with just one machine, instead of having to purchase and maintain multiple different tools. Saving money and providing a more lean and effective workspace.

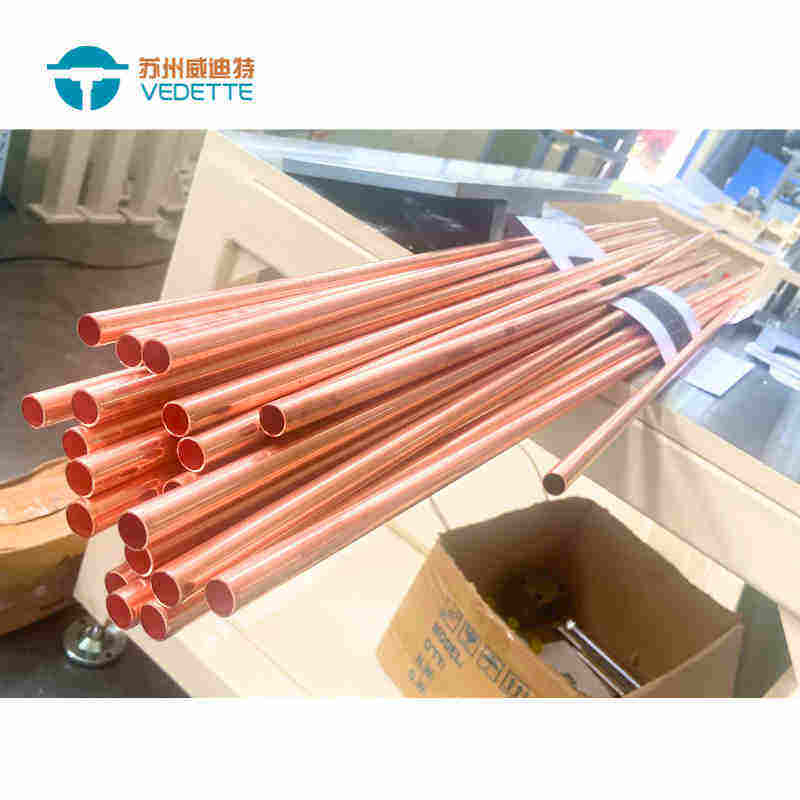

This quote is one of many we can say about our pipe CNC cut machines at Vedette They are made with cutting-edge technology, with state-of-the-art laser cutting and automatic feeding systems. All these modern features assist in making the entire cutting process faster and more precise, ensuring every product is made to precisely identical specifications every time. Such reliability is invaluable for businesses that require high quality in their products.

Pipe CNC cut machine will give your business a more extensive capability. Adding such a device will let you expand your line by producing higher-quality products faster and more accurately, allowing you to tackle more ambitious projects. Essentially, it allows you to serve your customers better and fulfill their needs more efficiently. You get further benefit as automating will help save money and increase productivity which you can reinvest in your business.

That said, if you are looking for pipe CNC cut machines the chances are that you are a business — and at Vedette, we know what big and small businesses need when it comes to pipe CNC cut machines! We have a model that will suit your needs, be it for small scale production or large industrial operations. And with our expert technicians and engineers on hand for support and maintenance, we ensure your machine is fully operational. This support ensures your operations are running uninterrupted.

Our pipe cnc cut machine has been manufacturing pipes processing automation equipment for more than 10 year and we have over 1,000 design plans that aren't conventional. After a thorough understanding of the needs of our customers and requirements, our experienced sales team will tailor services. Our equipment is produced and debugged according to the project planning process. Customers can monitor the equipment's assembly and debugging progress online at any time. Once the equipment is accepted by the customer, they'll conduct an the exit inspection in accordance with the exit delivery process to ensure that the equipment can be quickly put into the customer's factory production process. We have an efficient record of equipment and data. All data about equipment and customers are stored in paper files as well as electronic files. The mold updating service could be utilized to produce drawings or to provide Customization. After-sales assistance is provided by our professional team.

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the industry. It places great emphasis on pipe cnc cut machine, research as well as development, and has launched new products that are competitive to meet the constantly changing demands of the marketplace. We are committed to provide you with expert services that include pre-sales consultation and sales technical support and after-sales service. This will ensure that clients receive prompt and effective solutions. Our products can be applied for a wide range of industries. For users in need of equipment for pipe processing, Suzhou VEDETTE is undoubtedly the most reliable choice.

Suzhou Vedette Industrial Equipment Co., Ltd. was pipe cnc cut machine in 2011, located near the stunning Taihu Lake in the southwest of Suzhou, a hub of innovative clusters of the manufacturing of equipment. With more than a decade's expertise in the research, development and manufacturing of tube processing equipment, as well as different kinds of customized automation production lines and is a leading National high-tech company engaged in the design and manufacture of technologically-advanced, automated and advanced equipment. As of December 2022, it had 31 utility model patents and 10 invention patents on equipment. The equipment is well-received domestically and internationally, with customers from all over world. The company is committed to its corporate goal of offering quality products and services that add value to customers and is dedicated to becoming a pioneer in the advancement of technology for tube processing equipment in China.

To ensure consistency and excellence in product quality To ensure quality and stability in our products, we follow the premise of quality first and then take additional measures such as control of the source controlling the production process as well as continuous improvement. We will keep adhering to the quality-first principle in the future and improve our products and services to deliver pipe cnc cut machine to our customers.