The video discusses a CNC stamping press, which is an awesome device used to create different things from metals and other substances. Think of it CNC spinning machine as a large robot that is able to understand and follows orders given by any computer. This machine can create a large number of various items at fast that too with high precision which is why it becomes very useful in factories and manufacturing.

Metal products were made by hand before the invention of CNC stamping press. It was a long and difficult process. It required skilled and meticulous labour — but one slip could prove catastrophic. With the CNC stamping press, however, production can be done much faster and more precisely. This Vedette intricate manner of vending is consciously valued in sewing because it allows businesses to manufacture more products by using less time, cutting down. And if you make products cheaper to produce, then they can be sold more cheaply and in larger quantities.

CNC Stamp Press One of the main advantages to using a CNC stamp press is that an identical item can be recreated over and over again. This 13 CNC pipe bender ensures that each part will be identical to every other of the same type and accompany in perfect order, all while ensuring top-notch quality. Speed is another advantage the businesses get it done much many manual methods in a short duration without extra cost, where CNC stamping press acts very fast. Finally, when your require thousands of pieces to be produced every day there will have only two resolutions- either person has to do all the work which leads towards large human power and inventory or should use a CNC stamping press. This Vedette is as the machine does most of your heavy lifting which ensures safety to workers.

CNC metal stamping presses; Not only are specially designed tools created for cutting and shaping of metals as well. Those tools are controlled by a computer that 20 CNC pipe benders tells it every move to make. With this automatic control over the computer system, there is hardly any chance that the parts produced by a CNC Stamping Press would go wrong in terms of quality and precision. In addition, the computer can also inspect parts in real-time as they are being produced to make sure that everything is correct. This Vedette means that all the pieces will work together seamlessly, leading to a well-built final product up to spec.

In other words, the bottom line is used to describe a company's net earnings or profit. CNC stamping presses can create items fast and with high accuracy, which saves companies quite a bit of money on production costs. This 30 CNC pipe bender, in turn, causes them to need less workers to produce these items allowing for higher quantity production with shorter timeframe of preparation. It allows them to receive more pay without consuming any money on the process of producing their products and that is very good for business.

Recent advancements in CNC technology have only made them even better machines. In particular, while the CNC stamping press of old was never particularly slow or inaccurate there are now some exceptionally fast and accurate models coming out. In addition, they 40 CNC pipe bender have the capacity to work with a profound number of materials allowing them create even more varieties. In addition to this, CNC stamping presses are able to use 3D drawings now as well and these machines allow them make even more complex pieces of work with higher detailing.

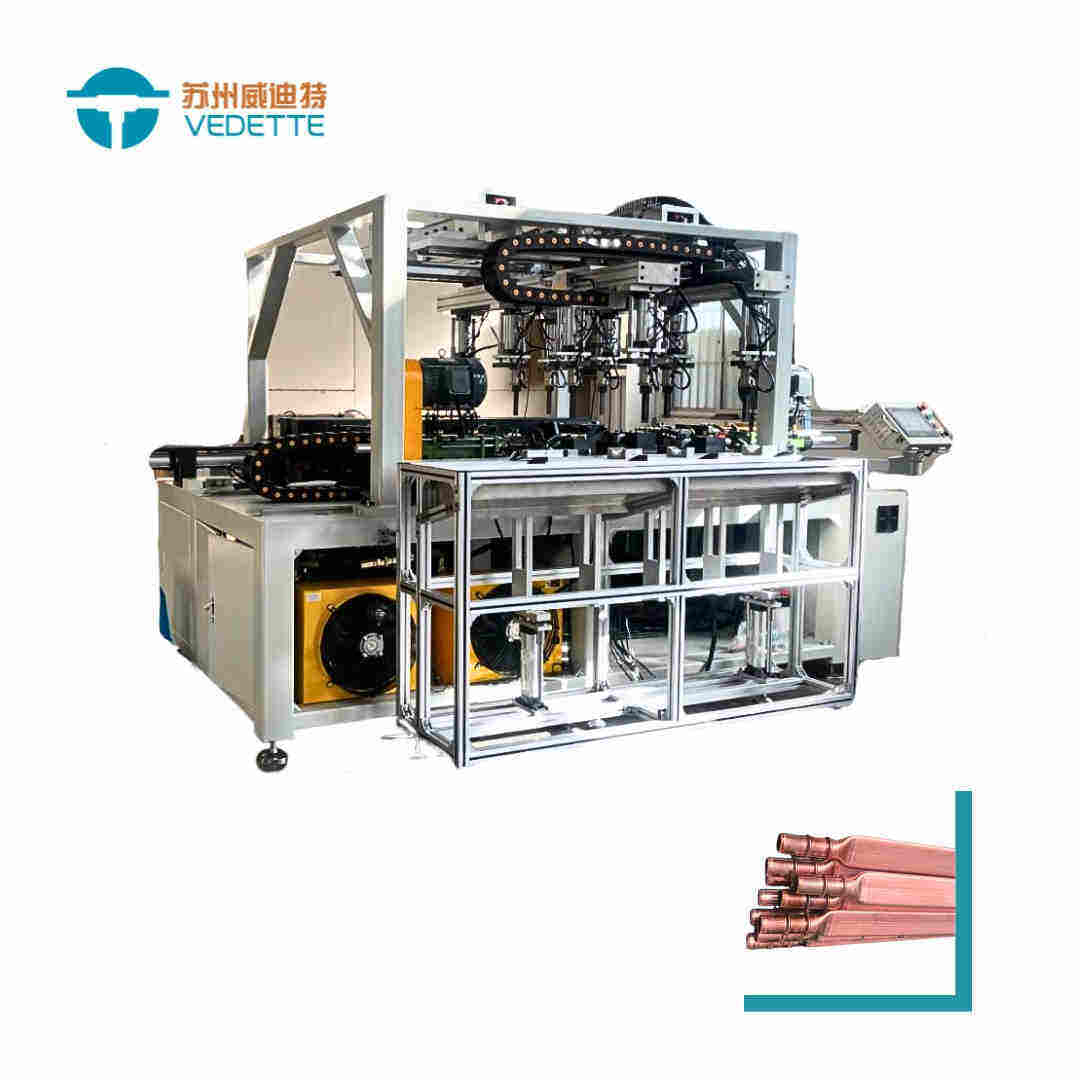

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the manufacturing of equipment. With over a decade of expertise in the development, research and manufacturing of tube processing equipment as well as different types of custom-designed automation production lines, it is a national high-tech company that is involved in the design and manufacture of technologically automated and sophisticated equipment. As as of December 20, 2022, it had 31 utility model patents, and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, serving clients across the world. The company adheres to its corporate goal of offering quality products and services that add value to customers, and is committed to becoming a pioneer in the field of technological advancement for tube processing equipment within Cnc stamping press.

Suzhou VEDETTE, as a Cnc stamping press manufacturer of pipe processing equipment in the market, puts an immense importance to technological advancement and research and development investment and is constantly launching new products with market competitiveness to meet the ever-changing demands of the market. We are committed to quality of life, customer experience as our main goal, to provide you with a full range of professional services including pre-sales support as well as sales technical support after-sales support, to make sure that customers have access to of prompt and efficient technical assistance and solutions. Our products offer a broad application to meet the demands of different industries in pipe processing. For the users who need pipe processing equipment Suzhou VEDETTE is an ideal choice.

We are the one-stop supplier for Cnc stamping press, offering a variety of equipment to satisfy your needs. We have been working in the field of automation for pipe processing equipment for more than 10 years, and have over 1,000 designs that aren't standard. Our sales professionals are experienced and can tailor services after detailed understanding of customer demands. Our equipment is designed and tested according to the project plan. Customers can monitor the equipment's assembly and debugging progress online at any time. They will conduct an inspection at the exit point in strict compliance with the departure delivery process once the equipment is approved to ensure that the equipment can be quickly integrated into the factory production processes of the customer. We have a data and equipment archive system that is perfect. The information of the customer's equipment is kept both digital and paper formats. Mold updating may include illustrations or Customization. After-sales assistance is provided by our expert team.

We have always Cnc stamping press high-quality as the primary objective by ensuring that we control the source monitoring of production processes, continuous improvement and other measures to ensure the highest quality and consistency of the quality of our products. We will keep adhering to this principle in the near future, and will continue to improve our products and services in order to offer greater value to our customers.