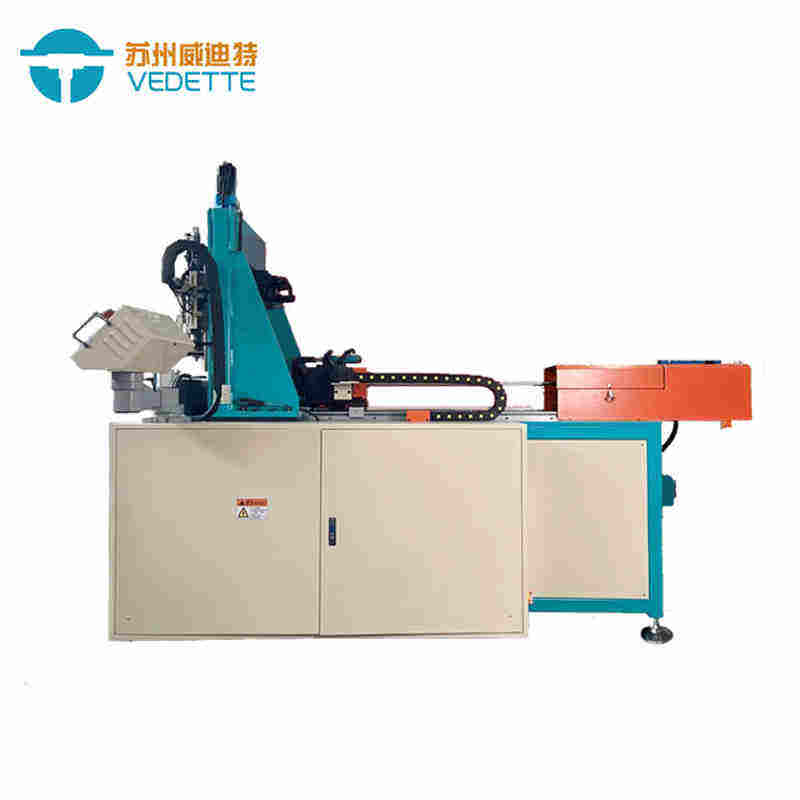

Machines, obviously, and new BFFs recognising how to do anything faster. The Vedette single-shaft punching machine simply assist us in doing our work with ease and faster while maintaining accuracy when we build something. An incredible piece of machinery that has turned into something of an industry legend in the fabricating world is a CNC tube punching machine and like it sounds, these work with tubes where this small contraption can penetrate holes using its brain (read: computer) from one side to the other as needed. While freehand turning has technically evolved, it may be the most rare evolution of what is better know traditionally as CNC. Computer Numerical Control: The computer does whatever it will do. Stream video stereotype machine learning So you can make sure that all of the holes being punched into those tubes are perfectly even. Through this technology the work becomes quite easy for everyone and, therefore it works more faster than that.

We Make a Hole, Such As Tube One such out of the many punching tools is CNC tube punching machine as it does precision hole sawing in tubes which are produced exactly where they are needed & hence, is a vital tool. The machine is also capable of hole punching tubes which are liberated from diameters to shapes and that allows us the ability to fabricate all kinds of components. It is able to process small punctured holes or macro ones. It can reach the difficult spots that a person alone would be able to get to This means it is an excellent tool.

Machine is made to work with efficiency to do its job at the best of its ability. The best of all it is a CNC tube Punching machine Vedette which was especially created for optimum time-saving and fewer mistakes when drilling into tubes. In some industries like finance where time is money, this velocity can be critical. The item is depend on-able and signifies it may ultimate a long very prolonged time76. They will also have this machine because it is extremely vital for businesses like car & aircraft manufacturers to complete their work. You can trust this machine because its function has no compromise at any time.

Flexibility in turn requires that you change from situation to situation. This tube punching machine is effective and can work on many different kinds of tubes with a variety of sizes and shapes. Whether you hail from a cold climate or warm one, tubes are snow tube universal. Those holes have to be punched accurately in each tube and this machine will make it happen. The machine is also on the in feed side of everything so it can adjust where to punch holes at some point down a tube which makes this a great tool for creating many types of tubes. The flexible end effector allows for the same machine to produce various products in different sizes, saving time and cost.

When it comes to cutting-edge, if we are talking in literal terms that would mean the most advanced or best version of technology. In terms of design elements that make it work faster and more efficiently than ever before, the CNC tube punching machine is on the cutting edge. It has an auto-feeder that can load tubes exactly right (shown). Keeps the device running without interruption, to load materials. Its laser measure also ensures that no one hole is ever misplaced. This Vedette Products slowly brings us to one of the other things that are supposedly making tube punching easier and, hopefully better—the new iterations come with more features on them than if you were to purchase your machine a year or two ago. And the better quality it is, the happier customers are going to be and higher businesses can perform.

We have always Cnc tube punching machine high-quality as the primary objective by ensuring that we control the source monitoring of production processes, continuous improvement and other measures to ensure the highest quality and consistency of the quality of our products. We will keep adhering to this principle in the near future, and will continue to improve our products and services in order to offer greater value to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. It is a high-tech enterprise in the nation that has more than a decade's experience in research development, manufacturing and customization of automation production lines. In December 2022, it held Cnc tube punching machine utility model and 10 invention patents related to equipment. The equipment it produces is highly sought-after both in China and around the world, with many customers.

Suzhou VEDETTE is Cnc tube punching machine leading producer of pipe processing equipment in the field. It focuses heavily on technological innovation, research and development, and launches new products that compete to meet the ever-changing demands of the marketplace. We are committed to quality of life and customer experience as our main goal we provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance, to ensure that customers get the benefit of timely and professional technical assistance and solutions. Our products have a wide range of applicability to meet the requirements of various industries that require pipe processing. For the users who need pipe processing equipment Suzhou VEDETTE is definitely an excellent choice.

Cnc tube punching machine company is manufacturing pipe processing automation equipment for more than 10 year and we have more than 1,000 designs that are not conventional. Once we have a complete understanding of the requirements of our clients and requirements, our experienced sales team can tailor the services to meet your needs. The project planning process is followed to manufacture and debug our equipment. Customers can watch the equipment assembly and debugging progress online anytime. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to ensure that the equipment is promptly incorporated into the customer's factory production tasks; We have a perfect data and equipment archiving system. The customer's equipment is preserved both in electronic and paper files. Mold updating can provide illustrations or Customization. After-sales support is provided by our experienced team.