Tube cutting machines are a type of special tool which helps cut the pipes to shorter length and smaller sizes. These are, in fact, called pipe cutters and they are a handy tool in many industries. To know more about the copper tube cutting machines read this article. In this article we will see how do they work, their features, its applications, how to select the correct blade size and its nominal performance as well common issues you may face while using them along with some valuable solutions to mitigate those.”

A tube cutting machine is used specifically to cut tubes extremely precise and fast. A rotating blade for nice and easy tube cutting. When the machines are used, an operator sets a tube into them; then the machine wraps a clamp around it to make sure that the tube will not move out of place. The tube advances toward the growing pole at a high speed, and during this advance, the blade spins rapidly. This feature is great for the tube to be cut by rotating the blade. The machine is said to have a control system, which will determine the length of the cut. Once the tube has been cut, it is removed from the fixture and the machine is prepared to be broken down and another tube readied. You can repeat this process multiple times, and it is fast and efficient.

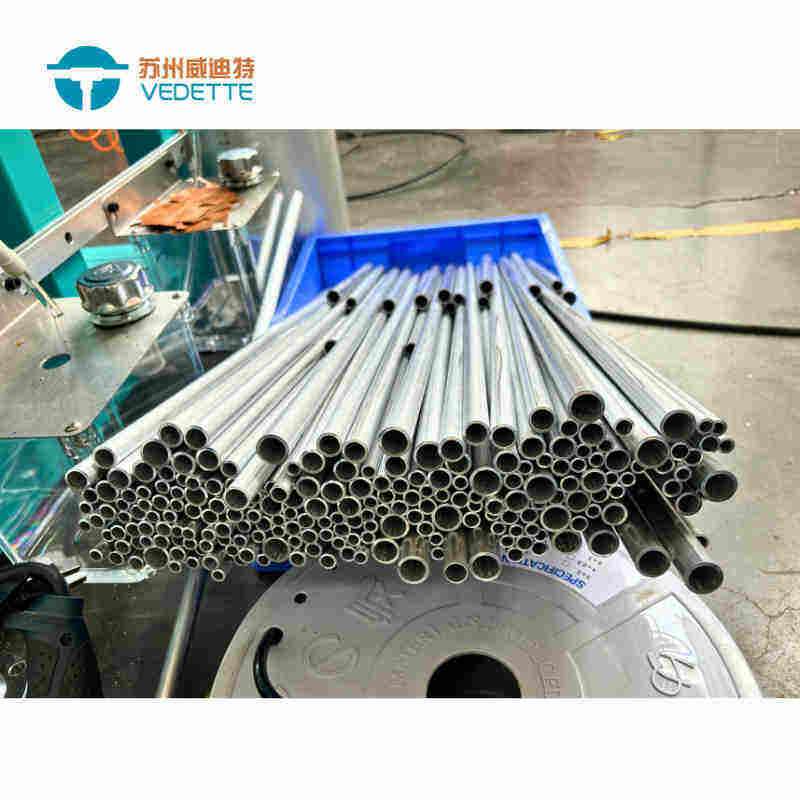

There are several top-notch features of Automated or Semi Automatic steel tube cutting machines. This is the most important aspect of their features. With the help of these tools, one can easily cut tubes with utmost precision up to 0.1mm! This gives you extremely precise cuts, aiding in doing a wide range of jobs. The major plus is speed. They are able to cut many tubes in a much shorter span of time helping workers finish their job faster too. Certain tube cutting machines also incorporate automated feeding systems. This allows the tubes to be fed into the machine completely autonomously, saving time and freeing up workers for other jobs.

There are a variety of different fields and industries that rely on tube cutting machines in order to produce their products. These find wide and major applications in construction, automotive (car making), aerospace (airplane making) and plumbing (water & gas systems). Tube Cutting Machines are common in construction, and they are used to cut pipes needed for heating and air conditioning systems. In the automotive space, for example to cut exhaust pipes that keep cars noticeably silent and unbothered. Machines of this type are significant to the aerospace industry, where tubes used in aircraft parts such as landing gear and hydraulic systems need to be cut. In plumbing, tube cutting machines are used to slice the pipes used in water and gas supply systems, which is necessary for everything to work as it should.

In tube cutting machine, blades are an essential component. Efficient and accurate cutting can only be done if the right blade is chosen. As the blade spins quickly it must be able to endure pressure in its force. Tube cutting machines are usually equipped with high-speed steel blades, which can withstand heavy use and are not deformed easily. Another choice would be carbide blades. More powerful than high-speed steel blades, they can penetrate stronger materials, but are typically more expensive. Tungsten carbide blades are the perfect option for all thickness of stainless steel and other tough materials here. They are made to do these harder tasks and do them well.

When you take a look at the usage of tube cutting machines, you will notice that some challenges come along with it. They are marked by the burrs. Burrs are the jagged edges that appear on a cut tube after cutting it with a saw, making the final product unsightly. Sharp blades cut cleanly; blunt blades cause burrs, as do incorrect cutting speed. This can be remedied by using a deburring tool or a blade that is strong enough to avoid burrs removing them as they cut.

A tube deformation is another challenge that you can encounter. This occurs when the length of a tube is distorted during being cut, by clamping it too tightly or de alignment. It is important to set the clamp pressure at the correct level so as not to deform the tube and one should always be sure to align with the blade before cutting.

tube cutting machine was founded in 2011 and is located close to the gorgeous Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the production of equipment. With more than a decade of expertise in the development, research and production of tube processing equipment and various kinds of custom automation production lines that are a national high-tech company that is involved in the development and production of technologically automated and intelligent equipment. As in December 2022 it has 31 utility model patents, and 10 equipment invention patents. The equipment is well-received both domestically and internationally, with clients across the world. The company abides by its corporate goal of offering valuable products and services for its customers and is dedicated to being a leader in the field of technological advancement for tube processing equipment in China.

To ensure stability and quality in product quality, we adhere to the concept of quality first as well as take other steps like tube cutting machine of sources, monitoring the production process, and continual improvement. We will continue to adhere the quality-first principle in the near future, and will continue to improve our products and services in order to provide greater value to customers.

Our company has been manufacturing pipeline processing automation equipment for more than 10 year and we have over 1000 designs that are not typical. Experienced sales projects will customize services based on a thorough understanding of the needs of customers. Our equipment is designed and tested according to the project design process. Customers can follow the equipment's assembly and debugging process online anytime. When the equipment is approved, they will carry out the inspection of exit in line with the process of exit delivery to ensure that the equipment can be swiftly integrated into the customer's factory production processes. We have a flawless storage system for data and equipment. All tube cutting machine about equipment and customers are preserved in paper files and electronic files. The mold updating service could be used to draw sketches or custom. After-sales assistance is provided by our team of experts.

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an tube cutting machine importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.