Bending metal was an involved chore before the days of CNC machines, it required elbow grease and hours. Metal had to be bent by hand, or certain kinds of equipment, and transforming the material was not necessarily a process that could publicized. At times they would fuck up and need to re-build from scratch. Now, with the CNC bender, you just need to program it for how exactly do us want that metal shaft bend and it will done within accuracy. So naturally one would assume that fewer errors and better products. The Vedette Pipe bending machine is constructed in a way that it provides the most accurate bending in metal, and accuracy plays an important role from quality point. in the modern era, businesses can rely on it to produce high-quality metal products in a short amount of time. This translates to the ability for companies who put products into production faster are able to meet customer need easier.

CNC bender is an automatic machine to make a deal with metal work pieces much more faster than ever. For starters, it never has to take a break and can perform the same bend time over. This contrasts with tasks that need to be accomplished by human employees who have limits on their work hours and will require breaks. Through CNB bending, companies can significantly reduce the number of employees who bend metal and therefore save time (and money). This enables them to produce higher number of products with lesser time and lower cost. This meant that, what previously took hours for a company to bend metal manually was now accomplished in minutes with only the push of one button using CNC. And this efficiency is a massive advantage in the business world.

The CNC bender can shape metal and other materials into chairs or tables, for a unique smart furniture home interior. There are also several different applications such as being able to manufacture metallic parts for machines, rockets or vehicles. With a CNC bender there are countless things you can do with it. This Vedette 40 CNC pipe bender freedom to personalize goods lets businesses create unique items and separates themselves from their competitors.

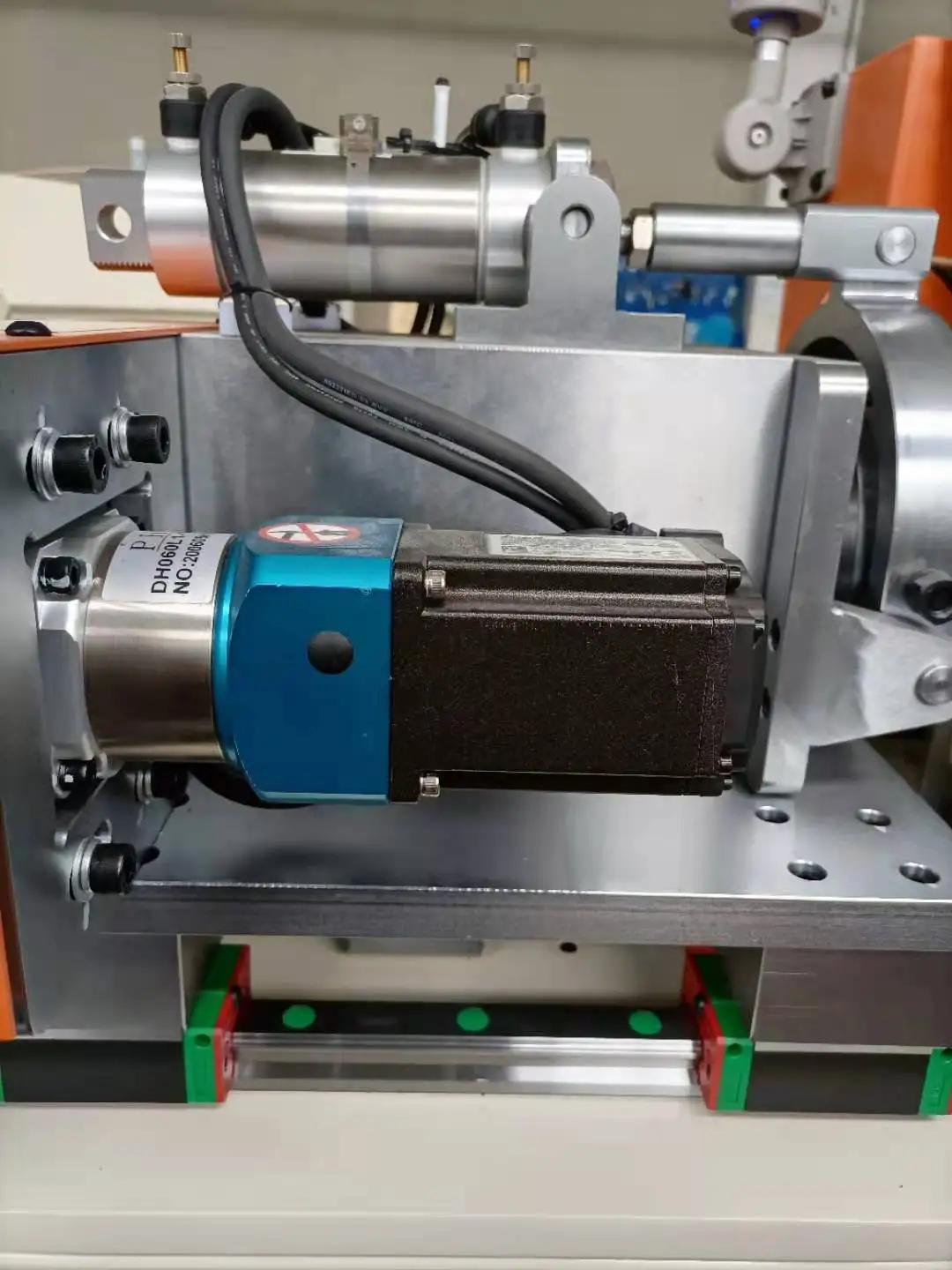

CNC technology is able to enable the CNC bender working at a fast speed and accuracy. The machine can bend round metal tubing with the aid of computer operations which in turn makes it a perfect bending giving 70degree bends. Therefore this will help businesses create many metal products at a larger scale without compromising the quality.

This makes the CNC bender ideal for mass production of metal products. That is often done by companies around the globe to get high-quality metal objects and save a lot of money. For instance, if a business needs to create elements in the thousands for an automobile using, then the Vedette 20 CNC pipe benders will certainly obtain this done swiftly as well as makes sure that every part coincides causing great manufacturing criteria.

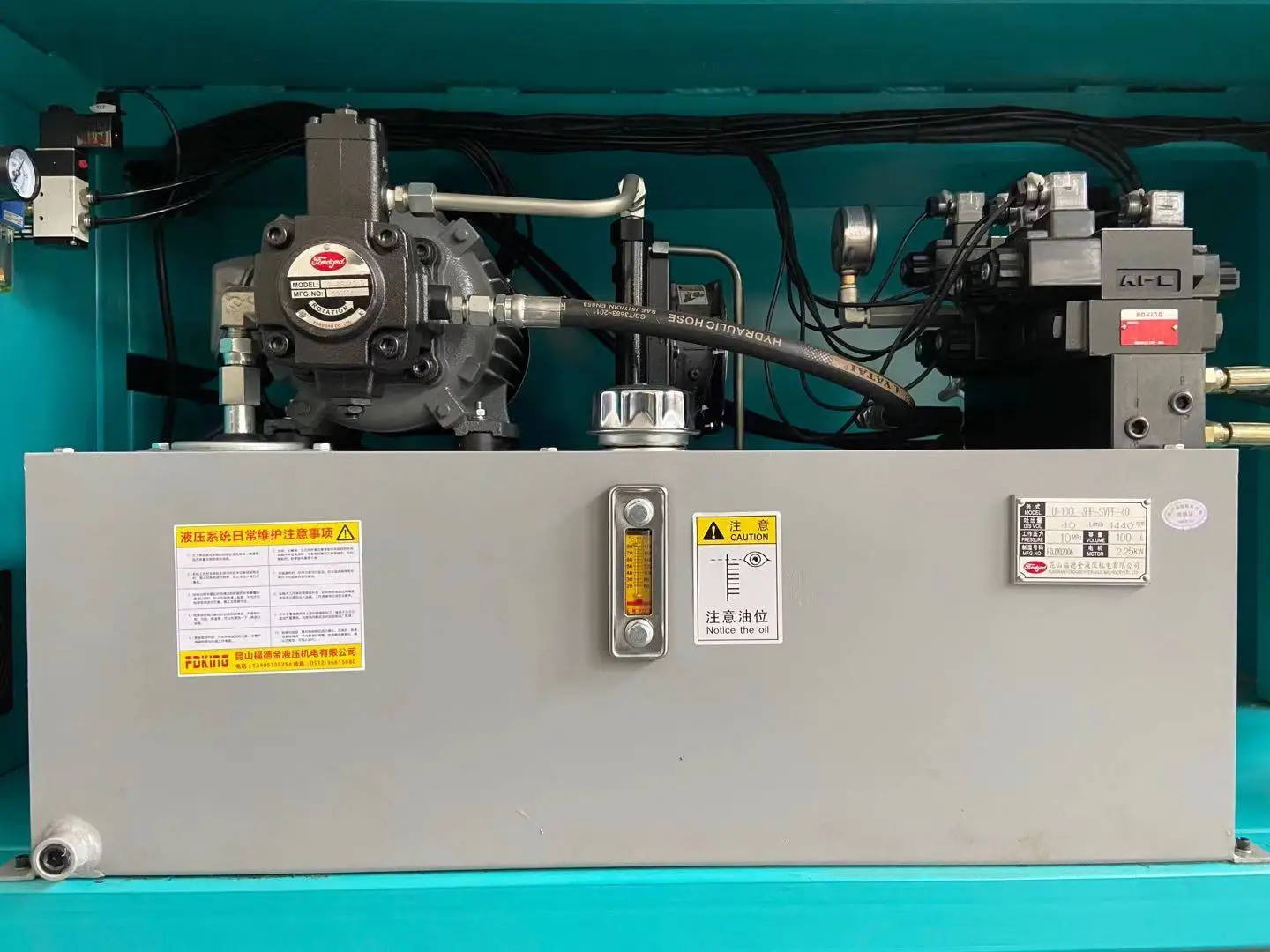

We are the one-stop supplier for Cnc bender machine, offering a variety of equipment to satisfy your needs. We have been working in the field of automation for pipe processing equipment for more than 10 years, and have over 1,000 designs that aren't standard. Our sales professionals are experienced and can tailor services after detailed understanding of customer demands. Our equipment is designed and tested according to the project plan. Customers can monitor the equipment's assembly and debugging progress online at any time. They will conduct an inspection at the exit point in strict compliance with the departure delivery process once the equipment is approved to ensure that the equipment can be quickly integrated into the factory production processes of the customer. We have a data and equipment archive system that is perfect. The information of the customer's equipment is kept both digital and paper formats. Mold updating may include illustrations or Customization. After-sales assistance is provided by our expert team.

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an Cnc bender machine importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.

We have always Cnc bender machine high-quality as the primary objective by ensuring that we control the source monitoring of production processes, continuous improvement and other measures to ensure the highest quality and consistency of the quality of our products. We will keep adhering to this principle in the near future, and will continue to improve our products and services in order to offer greater value to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. It is a top-quality national enterprise that has over 10 years of experience in research, development, manufacturing, and modifying automation production lines. As of Cnc bender machine it was the holder of 31 utility models and 10 patents on inventions of equipment. Its equipment is highly regarded both in China and abroad, with many customers.