Machines are getting better everyday — more and more, they can work on tasks with little need for human intervention. A CNC Machines Being everywhere, a special kind of encryption is known to grow. This machines are very cool because they can do anything you program them to quicker and better. Read this article to know how do varieties of products make with the help of CNC machines and why they are distinct in nature.

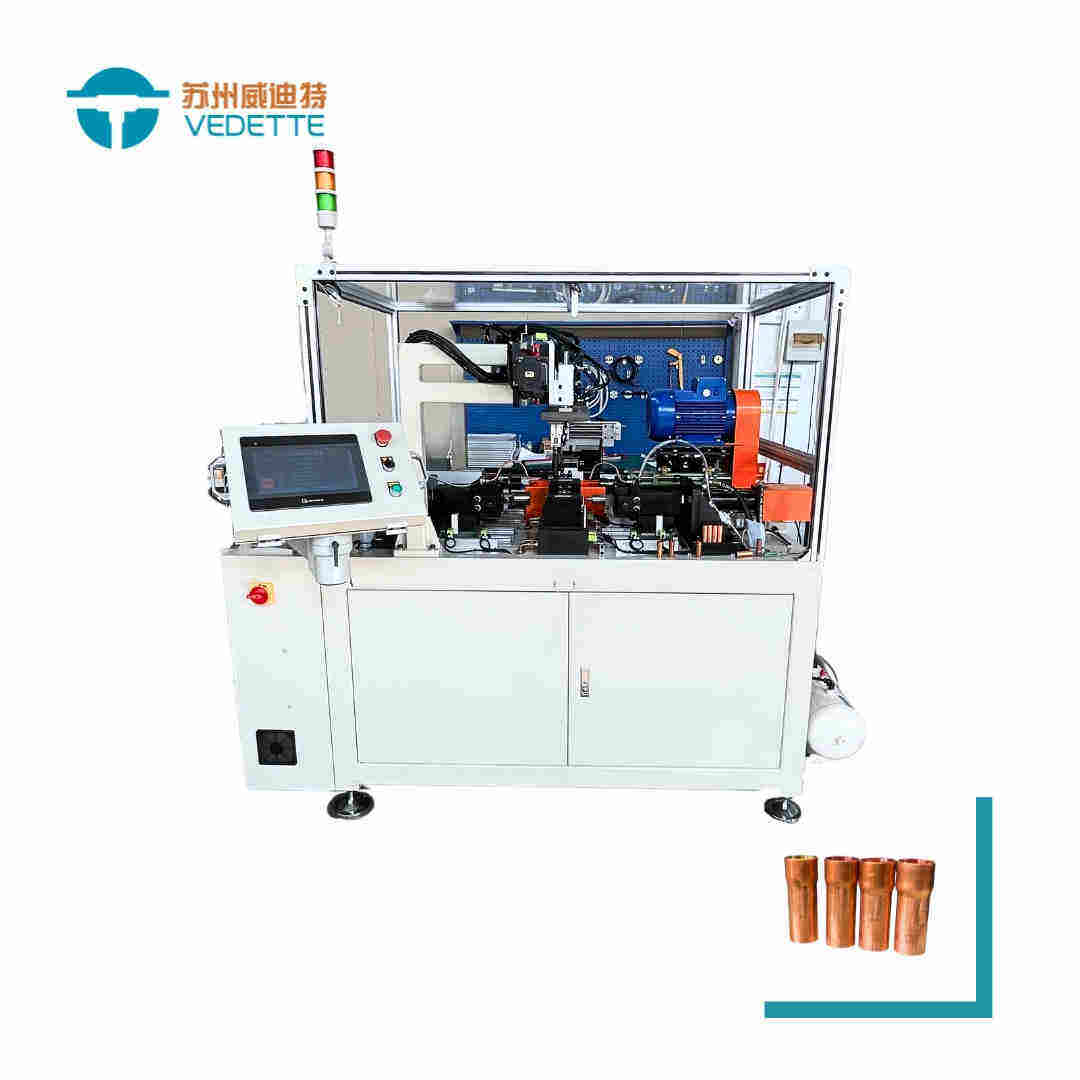

CNC — Computer Numerical Control This cnc pipe punching machine means that how these work will be controlled by the computers. CNC Machines are used in many different places that create things: such as factories making cars or airplanes, commercial embroidery machines, and of course computers for the home user. This Vedette machines are able to work from a computer design, it is able to make parts in three dimensions it can create very intricate and more complicated shapes.

This cnc tube bending is helpful in manufacturing industries as the CNC machines can make complex components quickly and with high precision without errors. Also, the way they are cut makes them an excellent choice for computer-based programs (CNC Machines) as unlike some of the older machines that you might need to make a lot of adjustments on first so that you knew it would set up properly every time. These Vedette are used for making a wide variety of various materials to be made, from metal and plastic, to wood and more. Well, because they are so versatile and able to do a job quickly, the more time the quicker you can make service in factories.

Accuracy is one of the few startling features of CNC machines. Very small measurements, sometimes down to 1,000ths of a millimeter or in micrometers can be produced accurately by a machinist. You need this level of precision for manufacturing medical equipment, which has to be very precise in order to function correctly. So, the appointment of CNC machines is very much right for the critical sectors such as Medical, aerospace, car manufacture etc. They make pieces that are perfectly matched and this is important since lack of exact matching between these parts can cause safety and quality issue outputs.

CNC equipment is designed to work fast and not make human mistakes while continuing to produce like parts over and over. Older machines may require breaks or tune-ups; however CNC machines can run 24 hours and 7 days a week, without ceasing. Has 100% of their items made in a factory (meaning they can churn out the goods fast but also always the same which Vedette cnc pipe bending machine price is essential for businesses who want to keep the product consistent)

If you have your own company and are wanting to manufacture more products, a CNC service is the best way to go. These cnc pipe bender price machines are extremely technologically advanced and will not only reduce your cost of producing any product but also help improve the quality. You can also operate machines with fewer workers, which could also save you money over time. This is particularly useful for young companies scaling up.

If you want to purchase just the CNC machine that is right for your business, it is important that you only consider what your business requires. One example is, if the objects you occupier making are detached in size then a huge CNC Machine that has an enormous perform part isn't planning to be of any profit (unless you'll square measures cutting massive format panels or foolscap sizes). This cnc pipe bender for sale article will help you a bit to get through all this research and find the best suitable CNC machine as per your requirement lying within budget.

We are your single-stop source for equipment to process pipes, offering a range of machines to fulfill your needs. We are Cn c machine on the field of automation for pipe processing equipment for over 10 years and have nearly 1,000 design concepts that are not standard. Sales professionals with experience can tailor services after detailed understanding of customer demands. Our equipment is designed and debugged according to the project schedule. Customers can watch the equipment assembly and debugging progress online anytime. When the equipment is approved and inspected, they'll carry out exit Inspection in strict accordance to the exit delivery procedure to ensure that the equipment will be promptly incorporated into the customer's factory production tasks; We have a perfect storage system for data and equipment. The data of the equipment used by customers is stored in paper files as well as electronic files. Mold updating will provide sketches or custom. We have a highly skilled service department after sales and can provide after-sales cleaning, maintenance and cleaning.

Suzhou Vedette Industrial Equipment Co., Ltd., founded in 2011, is located in Cn c machine located near Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a technologically advanced national company with more than 10 years of experience in research, development, manufacturing, and customizing automation production lines. In December 2022, it held 31 utility model and 10 patents on inventions of equipment. The equipment is popular both domestically and internationally, with customers from all over world. The company abides by its mission to provide valuable products and services for its customers, and is committed to being a leader in the development of technological innovations for tube processing equipment in China.

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an Cn c machine importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.

To ensure stability and quality in product quality We adhere to the principle of quality first, and take other measures like source control, Cn c machine the production process and constant improvement. In the future, we will continue to stick to the principles of quality first, constantly improve the level of products and services to bring more value to our customers.