How Shapes of Pipes Made for Buildings or Other Places are Achieved if you have seen pipes being made. Pipe making is not as easy as what it looks like since there are methods to make an individual pipe the usage of a multi-station pipe end forming machine. Most importantly, it is capable of very fast parts. As such, these machines can serve as excellent completes on pipe assembly in quantities.

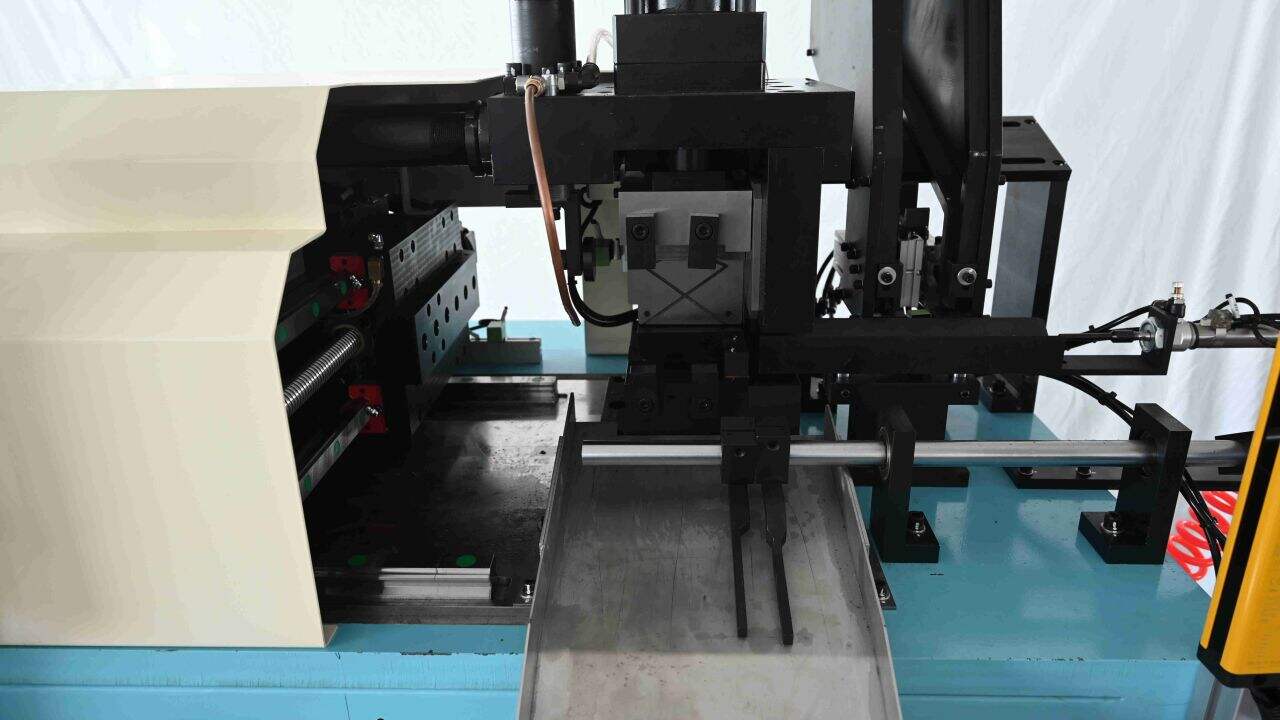

The pipe end forming machines multi-station enables the covering pipe end shaping with many tools. Some of these tools are known as mandrels. Mandrels are round, cylinder-shaped implements that help mold the inner lining of the pipe as it is being shaped. It is difficult to keep the inside of the pipe even and smooth without mandrels. The other major tool is something called a die. This end molds the exterior of the pipe. They influence the pipe’s appearance in the end. Some machines also form special shapes or patterns using punches or hammers. These tools collaborate to ensure that every pipe is manufactured accurately.

One big advantage of those machines is that they can make many pipes quickly. These machines can work on multiple pipes simultaneously, as they have various stations, each with its own full toolkit. So instead of producing a single pipe at a time, they can produce many pipes all at once. This enables companies to produce more pipes at a lower rate, and address what people need better. High demand for pipes makes these machines highly useful since they can meet the needs of builders and manufacturers.

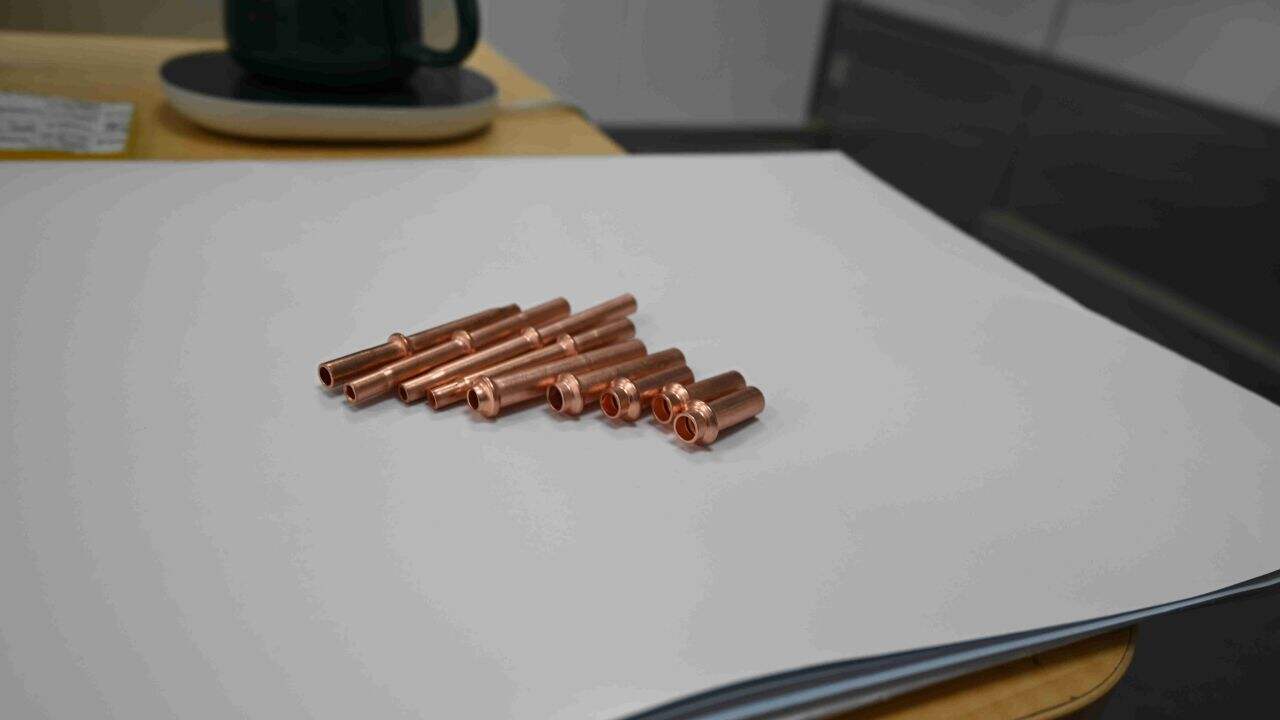

In addition to producing a lot of pipes, multi-station machines have other offsets, making their awesome performance. They can be used to discover different shape and sizes of pipes that can be used in number of jobs and projects. Some work even requires long pipes, and some require short or curved pipes. They can be adapted or modified to meet specific requirements, such as collaborating with other machines or processing specific materials. This makes them very adaptable to many different industries.

They are also very precise and accurate, which is another good thing about these machines. All the stations are purposeful, and so the pipes are produced clean and meet the highest quality standards. It is particularly important in jobs where safety and quality are paramount, such as construction and transportation. It may come to haunt you later, if the pipes are not done correctly. This is why every pipe-making plant needs to have the right machinery.

Our Multi station pipe end forming machine has been manufacturing pipes processing automation equipment for more than 10 year and we have over 1,000 design plans that aren't conventional. After a thorough understanding of the needs of our customers and requirements, our experienced sales team will tailor services. Our equipment is produced and debugged according to the project planning process. Customers can monitor the equipment's assembly and debugging progress online at any time. Once the equipment is accepted by the customer, they'll conduct an the exit inspection in accordance with the exit delivery process to ensure that the equipment can be quickly put into the customer's factory production process. We have an efficient record of equipment and data. All data about equipment and customers are stored in paper files as well as electronic files. The mold updating service could be utilized to produce drawings or to provide Customization. After-sales assistance is provided by our professional team.

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the industry. It places great emphasis on Multi station pipe end forming machine, research as well as development, and has launched new products that are competitive to meet the constantly changing demands of the marketplace. We are committed to provide you with expert services that include pre-sales consultation and sales technical support and after-sales service. This will ensure that clients receive prompt and effective solutions. Our products can be applied for a wide range of industries. For users in need of equipment for pipe processing, Suzhou VEDETTE is undoubtedly the most reliable choice.

Multi station pipe end forming machine ensure the highest quality and stability in the quality of our products We adhere to the principle of quality first as well as take other steps such as source control as well as monitoring the process of production, and continual improvement. In the future, we will continue to keep to the principle of quality first. We will continue to improve the level of products and services to bring more value to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. With more than a decade of expertise in the development, research and production of tube processing equipment as well as different types of custom-designed production lines for automation, it is a national high-tech company that is involved in the development and production of automated, technological, and sophisticated equipment. As in December 2022 it had 31 utility model patents and 10 patents for inventions of equipment. Its equipment is well-received domestically and internationally, with clients across the world. The Multi station pipe end forming machine is committed to its core mission of providing valuable products and services for its customers, and is committed to become a leader in the development of technological innovations for tube processing equipment in China.