Have you ever seen a blade-less machine that cuts pipe? That’s something Vedette has done with a really special machine! Their pipe cutting machine is an incredible machine that uses cool, cutting edge tech to cut pipes in an efficient and precise manner. This means you can achieve cuts that are perfect every single time with no fear of making a mistake or running into any issues.

Pioneer in Pipe Manufacuring uses Data & Machine Learning, which provides Guaranteeed Accuracy to Optimize each cut. This is done through hydraulic power—a powerful force that pushes the pipe into a special cutter. This tool was made in such a way that it does not hurt or damage the pipe in any way. As a result, the machine makes clean-cutting and precise for all the time. This signifies that the pipes remain prepared to be utilized for what they will be utilized for regardless of whether it is for development, plumbing or other significant employments.

The best thing about the Vedette pipe cutting machine is that it is very fast and accurate in its work. That allows it to snip many pipes in a brief span. This machine is really useful for when a business needs to cut a bunch of pipes in a short period of time. This machine enables workers to complete their jobs far more quickly than previously possible. As the speed of the machine helps keep everything running smooth, this is a very needs for companies to get their work done in a time efficient way, which this machine allows them to do so.

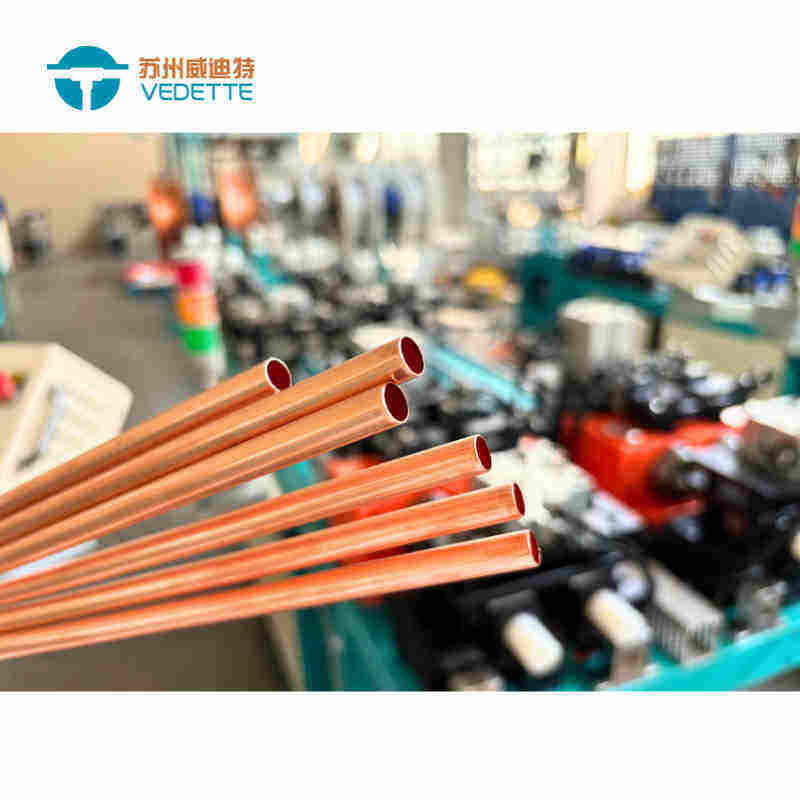

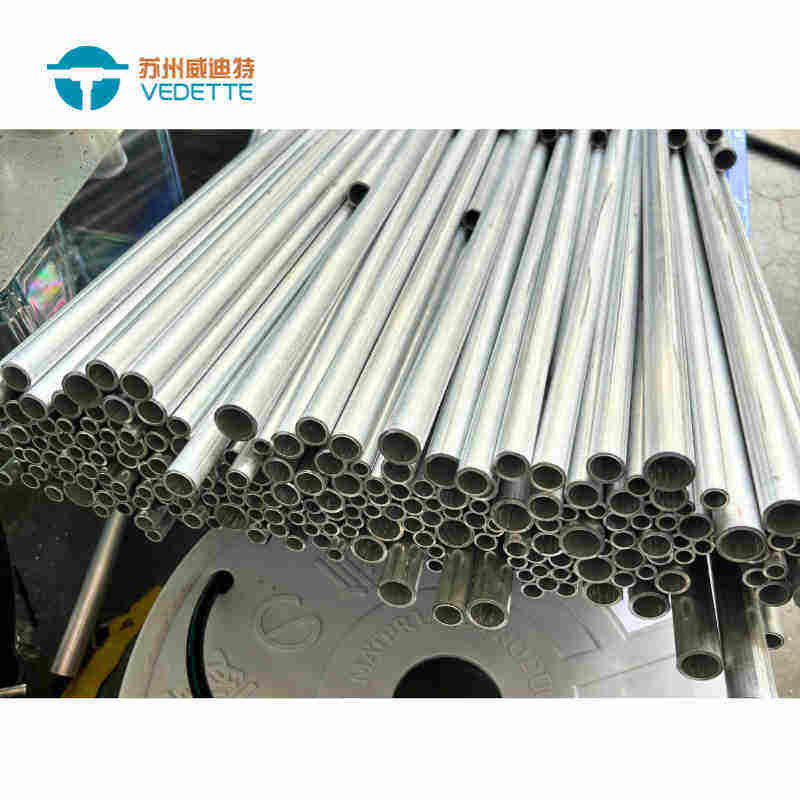

The Vedette pipe cutting machine is capable of cutting through so many other types of materials as well! It easily slices through steel, copper, and aluminum pipes. This makes it a very handy tool to have around, especially if you need to cut pipes that are made out of various materials. It can also cut pipes that are different sizes. Furthermore, this makes it even more practical for businesses and workers who have diverse cutting needs, as workers can use it for big and small pipes.

Since machines have their safety situations, Vedette has considered of making their pipe cutting machine comfortable as well as safe. It is constructed to only actually operate when a button is pushed. This means no accidental cuts or accidents, which is crucial for peace of mind all around. It is also a straightforward machine, so it is friendly for those workers who do not have experience in pipe cutting. Plus it is made to be durable so that workers can rely on it for good results every day, week after week.

To ensure stability and quality in product quality, we adhere to the concept of quality first as well as take other steps like Pipe chipless cutting machine of sources, monitoring the production process, and continual improvement. We will continue to adhere the quality-first principle in the near future, and will continue to improve our products and services in order to provide greater value to customers.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in southwest Suzhou in close proximity to Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a highly-tech national company with more than a decade's experience in research, development, manufacturing, and customizing automation production lines. At the time of its December 2022 launch, it was the holder of 31 utility models and 10 patents on inventions of equipment. The equipment it produces is highly Pipe chipless cutting machine both in China and around the world, with numerous customers.

Suzhou VEDETTE, as a Pipe chipless cutting machine manufacturer of pipe processing equipment in the market, puts an immense importance to technological advancement and research and development investment and is constantly launching new products with market competitiveness to meet the ever-changing demands of the market. We are committed to quality of life, customer experience as our main goal, to provide you with a full range of professional services including pre-sales support as well as sales technical support after-sales support, to make sure that customers have access to of prompt and efficient technical assistance and solutions. Our products offer a broad application to meet the demands of different industries in pipe processing. For the users who need pipe processing equipment Suzhou VEDETTE is an ideal choice.

We are your Pipe chipless cutting machine for equipment to process pipes offering a variety of equipment to fulfill your needs. We have been working on the field of automation equipment for pipe processing for over 10 years and are able to offer more than 1000 non-standard design patterns. After a thorough understanding of the customer's needs the experienced sales staff will tailor services. The planning process for projects is followed to manufacture and debug our equipment. The process of assembly and debugging can be viewed online by the customer at any point. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to make sure that the equipment is quickly integrated into the client's factory production processes. We have a flawless record of equipment and data. The information of the customer's equipment is preserved both in documents and in paper. Mold updating is a way to provide drawings or Customization. After-sales support is provided by our expert team.