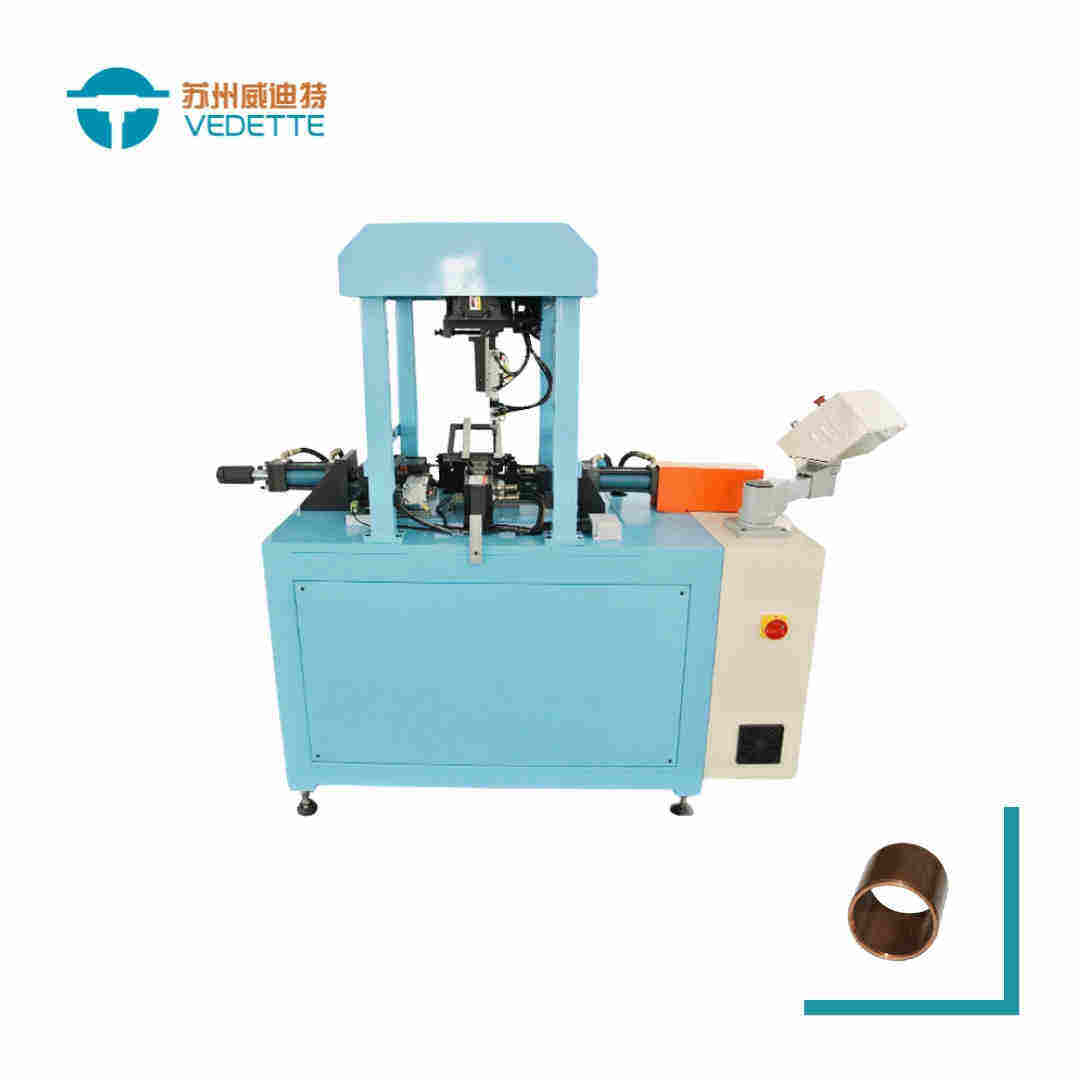

Do you know what a steel pipe shrinking machine is? It’s a nifty tool that makes a business’ pipes relatively smaller & more meaningful. We at Vedette, are proud to manufacture some of the best shrink pipe machines on the market. These machines are essential for numerous pipeworks related companies. Let’s dig into and understand more about how these machines work and why they are helpful!

So, the shrink pipe machine is an amazing invention, which works on the simple concept of heating up the pipe until it is soft and bendable. This makes the pipe flexible and allows it to change shape easily. Once the pipe is heated, a custom tool shapers the pipe to a smaller size. It is crucial to do so before us fixing the pipe into other places. Then, as it cools, the pipe retains its new form and calcifies. The process of heating and forming is known as heat shrinking. It helps companies make pipes the perfect size for their needs.

It helps quality: When pipes are shrunk with a machine, they are more uniform in size and shape. This also means they will all look and do the same thing which can enhance the quality of your products in general. Quality products are appreciated by customers and this can lead the way for business growth.

It’s eco-friendly: The pipe end shrinking machine enables the production of products in bulk which, in turn, cuts back on waste while saving energy. This is better for the Earth and also allows companies to prove to their customers that they are environmentally friendly.”

It saves money: Shrink pipe machines can help businesses save on materials and transportation costs, which is good for their profits. This makes it appealing for companies looking for a way to please their customers while saving money at the same time.

Know which temperature to use: The best temperature for heat shrinking depends on the type of pipe material. Be sure you know the correct temperature for the specific pipe you are working with. Doing so is critical to getting the best results.

Ensure your Machines are clean: Keep your shrink pipe machines clean and maintained regularly as this will give a better performance and maximise their life span, Cleaning cleaning machine will run more optimized and generate better results.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. It is a top-quality national enterprise that has over 10 years of experience in research, development, manufacturing, and modifying automation production lines. As of shrink pipe machine it was the holder of 31 utility models and 10 patents on inventions of equipment. Its equipment is highly regarded both in China and abroad, with many customers.

We are the one-stop supplier for shrink pipe machine, offering a variety of equipment to satisfy your needs. We have been working in the field of automation for pipe processing equipment for more than 10 years, and have over 1,000 designs that aren't standard. Our sales professionals are experienced and can tailor services after detailed understanding of customer demands. Our equipment is designed and tested according to the project plan. Customers can monitor the equipment's assembly and debugging progress online at any time. They will conduct an inspection at the exit point in strict compliance with the departure delivery process once the equipment is approved to ensure that the equipment can be quickly integrated into the factory production processes of the customer. We have a data and equipment archive system that is perfect. The information of the customer's equipment is kept both digital and paper formats. Mold updating may include illustrations or Customization. After-sales assistance is provided by our expert team.

We have always shrink pipe machine high-quality as the primary objective by ensuring that we control the source monitoring of production processes, continuous improvement and other measures to ensure the highest quality and consistency of the quality of our products. We will keep adhering to this principle in the near future, and will continue to improve our products and services in order to offer greater value to our customers.

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the industry. It places great emphasis on shrink pipe machine, research as well as development, and has launched new products that are competitive to meet the constantly changing demands of the marketplace. We are committed to provide you with expert services that include pre-sales consultation and sales technical support and after-sales service. This will ensure that clients receive prompt and effective solutions. Our products can be applied for a wide range of industries. For users in need of equipment for pipe processing, Suzhou VEDETTE is undoubtedly the most reliable choice.