There are many ways in which you can shape things even using Vedette stainless steel tube bending machine tools. These are really cool and they can do crazy stuff! You can make all kinds of things with these special tools that were difficult to do so previously. Top 5 Things You Need to Know About Bending Tools So That You Can Get the Best Use Out of Them.

Bending tools can seriously level up how you work, if you have a business that makes things. Long ago, maybe only to form so much as one piece you'd have required many different tools. Although Vedette stainless steel tube bending machine, you can produce every angle and profile in a single go. This means you produce products much faster and efficiently! Using bending tools will save you a great deal of time so that you can create more high-quality products for your customers.

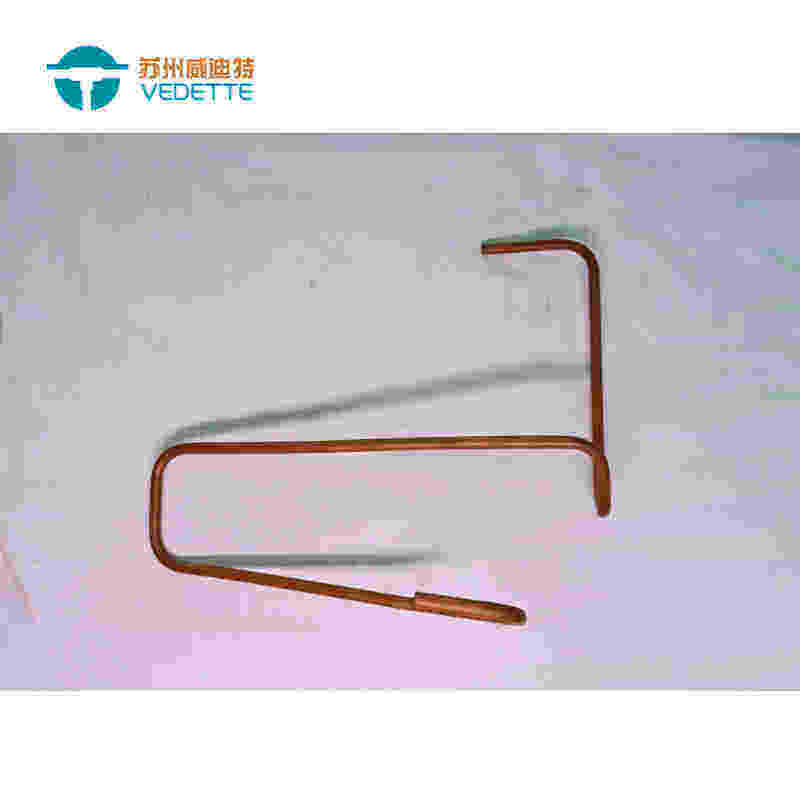

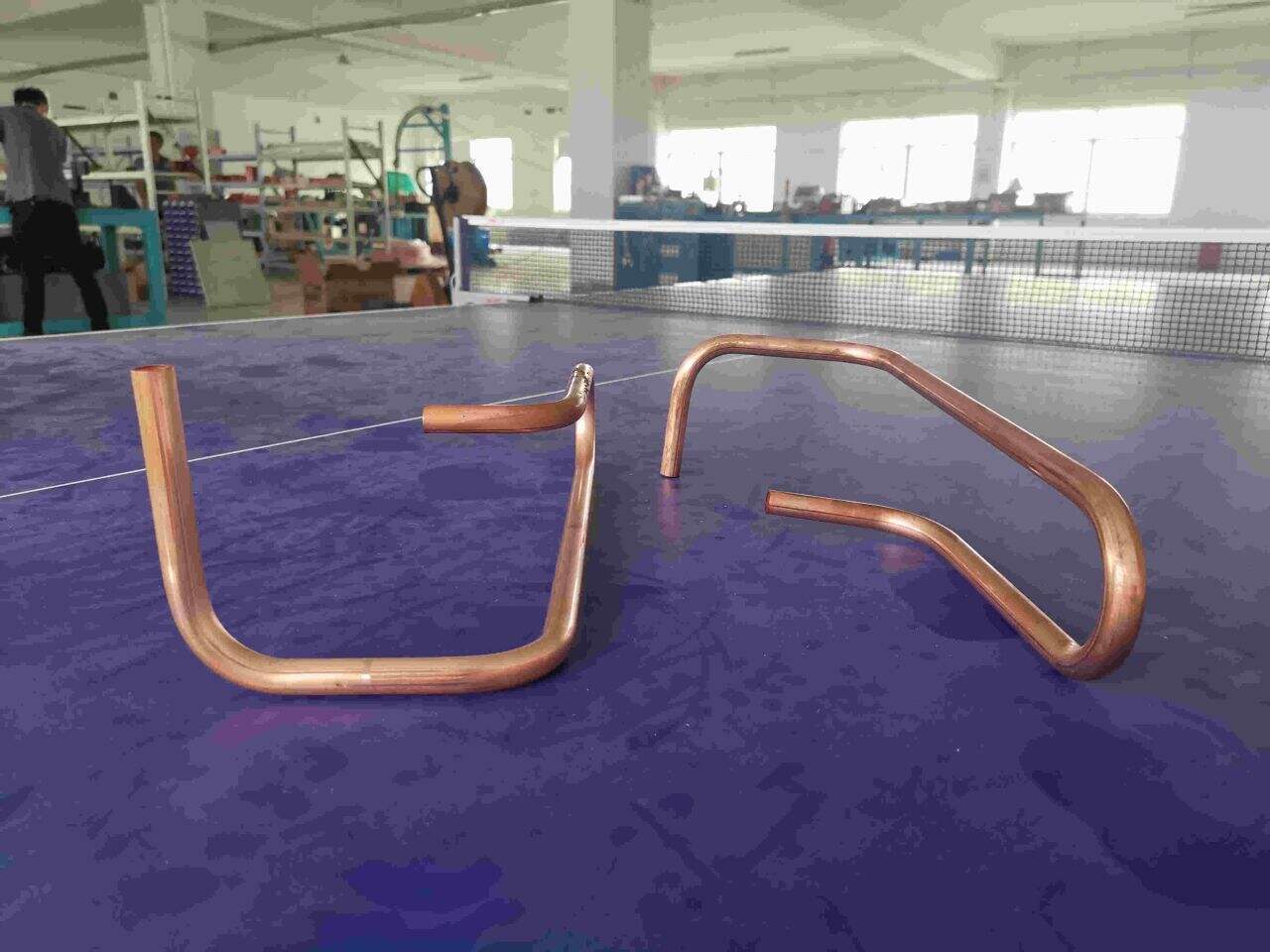

Find some good bending tools and use them to speed up the process. You don’t want to spend all this money on tools that might not work or break easily. Therefore, it is vital to carry out some research and procure suitable bending tools. What you could do is have a look at one these brands: Vedette. This includes a good quality selection of tools that you can use for all your bending needs. They have very durable Vedette copper pipe bending machine with top-of-the-line specs that automatically make their machines reliable and efficient.

For parts that need to be perfect but also have the nice aesthetics special Vedette copper pipe bending machine. These are the printing machines which can fabricate very precise parts in the same manner. This suggests that anything at all made with them is of the leading quality. Therefore, special bending tools are great if you want your business to produce quality goods that not only work, but also gladden the eye. We have different types of bending machines at companies like Vedette, they include a lot of unique features so as to help you find the one which is best suited for your needs.

Tools in bending is getting better and prototype making Vedette copper tube bender becoming easier and more precise all the time, with new ideas and technology being developed every day. Automatically loads/operates: Bending machines used to be operated manually in the past, but now a variety of bending machines can be automatically loaded and operated with a computer. It just makes it a lot easier to get the form and size you want. Touchscreens and more software allows you to create a much better version of what you want with less hands-on manual work. So, you can spend less time setting up, and more time making!

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the industry. It places great emphasis on Bending equipment, research as well as development, and has launched new products that are competitive to meet the constantly changing demands of the marketplace. We are committed to provide you with expert services that include pre-sales consultation and sales technical support and after-sales service. This will ensure that clients receive prompt and effective solutions. Our products can be applied for a wide range of industries. For users in need of equipment for pipe processing, Suzhou VEDETTE is undoubtedly the most reliable choice.

Suzhou Vedette Industrial Equipment Co., Ltd. was established in Bending equipment in the picturesque Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. With more than a decade's expertise in the development, research and manufacturing of tube processing equipment, as well as various types of customized production lines for automation It is a major National high-tech company engaged in the creation and production of technologically advanced, automated, and advanced equipment. As of December 2022, the company holds 31 utility model patents as well as 10 patents for inventions of equipment. Its equipment is highly regarded both in China and around the world, with many clients.

Our company has been manufacturing pipeline processing automation equipment for more than 10 year and we have over 1000 designs that are not typical. Experienced sales projects will customize services based on a thorough understanding of the needs of customers. Our equipment is designed and tested according to the project design process. Customers can follow the equipment's assembly and debugging process online anytime. When the equipment is approved, they will carry out the inspection of exit in line with the process of exit delivery to ensure that the equipment can be swiftly integrated into the customer's factory production processes. We have a flawless storage system for data and equipment. All Bending equipment about equipment and customers are preserved in paper files and electronic files. The mold updating service could be used to draw sketches or custom. After-sales assistance is provided by our team of experts.

To ensure stability and quality in the Bending equipment of our products We adhere to the premise of quality first and implement other measures such as control of the source as well as monitoring the process of production and continuous improvement. In the future we will continue to keep to the principle of quality first. We will continue to enhance the quality of our products and services to create greater value for customers.