Vedette would like to introduce our unique tube pipe cutting machines to all. These machines are literally designed to help people cut metal faster and easier. The kind of technology you use here is sophisticated such that the cutting is easy and fast. Their range of machines is particularly good for metalworkers, such as engineers, manufacturers and welders. Our goal at Vedette is to simplify the process of metal cutting for everyone in the metal industry and ensure tasks can be efficiently accomplished without any issues.

Vedette tube pipe cutting machines are very beneficial in metal work. For starters, automated machines allow the manufacturers to cut metal at a much quicker pace as compared to using manual ways. This agility is critical as it enables the employees to finish their jobs faster. Secondly, which extremely exceeds human accuracy on providing better cuts accurately. This helps in minimizing the chance of mistakes. What's more, the machines ensure that workers keep themselves safe while cutting, and reduce any chances of injuries or mistakes during the process. Our machines can make cuts that would otherwise be difficult and time-consuming, saving businesses money in the long run. They certainly do a great job compared to traditional cutting methods, providing cleaner cuts and facilitating faster production speeds.

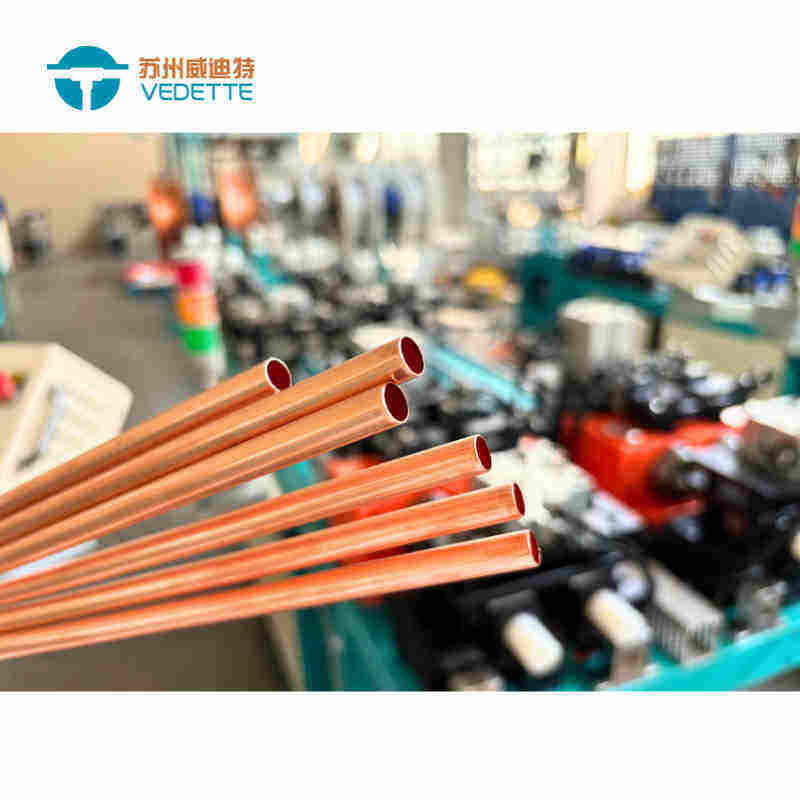

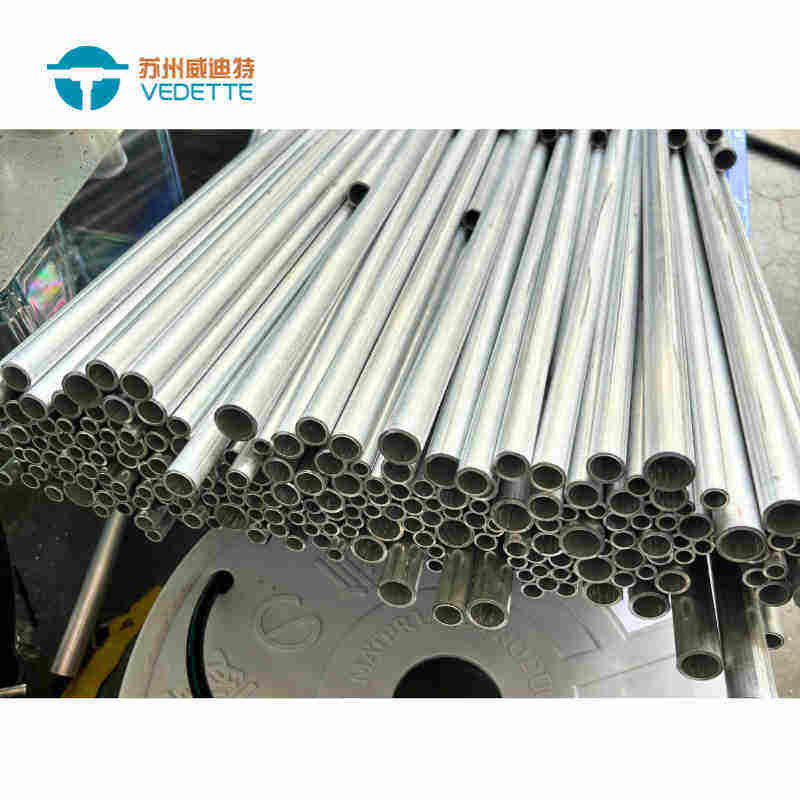

One of the great things about the machines from Vedette is that they are able to cut a wide variety of materials. This ranges from metals like steel, aluminum and copper to plastics. That versatility is what makes our machines so effective, since users can quickly and easily change materials when working on different projects. This function can assist you get many roles carried out with out requiring to modify right into a separate device that could prevent effort and time. From large pipes to small tubes, our machines can work with all sizes and shapes. It qualifies you with any number of choices this providing your job easily and giftable work.

So popular have been Vedette's tube pipe cutting machines in evolving how metal is cut that they are now the dominate selection across a myriad of industries. This also made the process of cutting metals more efficient and precise than it ever used to be. These machines can function in a large number of area from heavy machinery construction to the making art and jewelry. Our machines are quite critical to metalworkers and manufacturers for their high precision, speed and versatility. Our machines are guides for better metal cutting experience, this will continue to be resilient in a changing environment as the industry continues to evolve so that workers in may able focus with ease and confidence.

When you opt for Vedette tube pipe cutting machines, it can considerably enhance your proficiency and ability to work with any kind of metal. The best of our machines you can work with will enable you to have new customers as we help you deliver faster and more accurately than what is possible from the usual processes. It also enables you to scale your business so that you are able to take on bigger jobs without feeling as though the work is overpowering. Our machines can assist you to achieve fairly large projects or very precise cuts. This is the successful way to change your production and work quality and when you invest in our machines, it is more profitable for your business.

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the industry. It places great emphasis on tube pipe metal cutting machinery, research as well as development, and has launched new products that are competitive to meet the constantly changing demands of the marketplace. We are committed to provide you with expert services that include pre-sales consultation and sales technical support and after-sales service. This will ensure that clients receive prompt and effective solutions. Our products can be applied for a wide range of industries. For users in need of equipment for pipe processing, Suzhou VEDETTE is undoubtedly the most reliable choice.

Our company is manufacturing pipe processing automation equipment for more than 10 year and we have over 1,000 design schemes that are not standard. tube pipe metal cutting machinery sales teams can customize services based on a thorough understanding of customer demands. The process of planning the project is followed to manufacture and test our equipment. Customers can follow the equipment's construction and debugging progress on the internet anytime. They will conduct an exit inspection following the strict process for delivering the exit after the equipment has been accepted to ensure the equipment can be quickly integrated into the factory production processes of the customer. We have an archive system for data and equipment system that is flawless. The customer's data equipment is saved both in the form of paper and electronic files. The mold updating service could be used to provide drawings or Customization. After-sales assistance is provided by our expert team.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. It is a top-quality national enterprise that has over 10 years of experience in research, development, manufacturing, and modifying automation production lines. As of tube pipe metal cutting machinery it was the holder of 31 utility models and 10 patents on inventions of equipment. Its equipment is highly regarded both in China and abroad, with many customers.

To ensure stability and quality in product quality We adhere to the principle of quality first, and take other measures like source control, tube pipe metal cutting machinery the production process and constant improvement. In the future, we will continue to stick to the principles of quality first, constantly improve the level of products and services to bring more value to our customers.