This post is about machines and we are going to learn about a peculiar type of machine known as CNC machine. CNC: Computer Numerical Control These machines are one of the most special machines as it allows us to produce things with a high degree of care and precision. They are used in factories which produces a lot of stuff. Vedette is one of the companies manufacturing excellent CNC machines.

3 axis CNC Router machines are also very powerful and exact, the same as Vedette's tube chamfering machine. They are told by computers how to walk, just so that they make the desired items. Accuracy: For machine manufactures this is of great help, because these machines can produce many same items and every time it will be correct. Moreover, since they are so fast, it can work faster than a person. CNC machines are able to craft things from a variety of materials, such as wood, metal and plastics, just to name a few.

Technology such as CNC have revolutionized manufacturing, similar to the stainless steel pipe cutting machine from Vedette. Back in the good old days before CNC machines, everyone was making stuff by hand. The process was slow and error prone since it was so easy to err when working manually. Now a days we can manufacture more fast and less fault using CNC machines. This is perfect for businesses that need to create tons of a product in rapid succession. Through CNC machines we have opened doors to make things we could never do prior, enabling us to be innovative and improve our products.

They are computer-controlled machines that work with CNC (Computer Numerical Control) operations, same with Vedette's automatic chamfer machine. They are acquainted with special programs that order each CNC machine when to act and in which direction. This program is made for the machine by some expert who knows how to use computer software. When the program is ready, it can be loaded on the CNC machine. The machine then executes this program to manufacturer the item we desire. These are special tools on the CNC machine that cuts and shape the material it is working with. We can swap these tools out or update them as needed to make the things we need to make. Such customized can then work with a whole host of projects and Palletech setup sizes.

As its name implies, the movements are controlled by computers, so they are highly accurate, the same as tube chamfering machine created by Vedette. What this means is that if they make an object, they can make the same object again and again and it will always be identical. The computer is able to move them very carefully and accurately, allowing the artist to create even tiny details. It is this level of precision that makes it so good at creating parts that need to fit snugly together. Further, unlike people, who might take a moment to stop and determine what they are supposed to be doing, CNC machines can work quickly. This is time saving and more efficient in manufacturing.

The CNC machines are very essential to the entire manufacturing sector, as well as the Vedette's steel pipe cutting machine. They allow us to make things faster, more precisely and with better workmanship. As a result, many sectors today depend on CNC machines because of these benefits. They are worked into many different types of products that we use every day, from car parts and factory machines to furniture. Secondly, CNC machines have been involved in job creation. There are quite a few career opportunities for those trained and effective at building these applications and applying them using CNC machines.

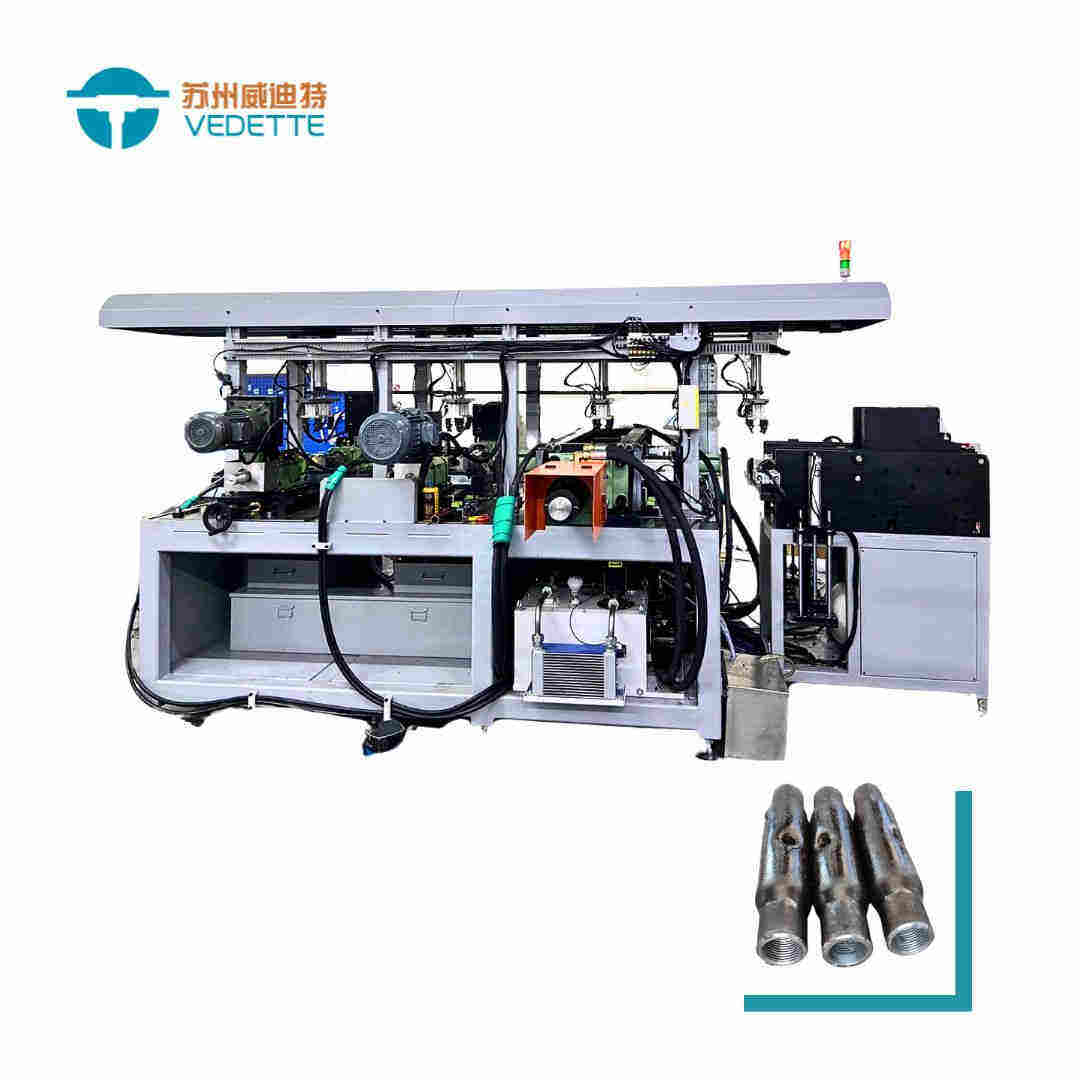

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the Machine cnc machine. It puts a lot of emphasis on technological innovation, research as well as development, and has launched new products that are competitive in keeping up with the changing needs of the market. We place quality of life, as well as the customer experience as the core of our business, and offer the full spectrum of professional services that include pre-sales consultation and technical support for sales, after-sales support, to make sure that customers get the benefit of professional and timely technical support and solutions. Our products have a wide selection of applications to meet the needs of different industries in pipe processing. Suzhou VEDETTE, a leading manufacturer of equipment for pipe processing is the best option for users.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. It is a high-tech enterprise in the nation that has more than a decade's experience in research development, manufacturing and customization of automation production lines. In December 2022, it held Machine cnc machine utility model and 10 invention patents related to equipment. The equipment it produces is highly sought-after both in China and around the world, with many customers.

To ensure stability and quality in the Machine cnc machine of our products We adhere to the premise of quality first and implement other measures such as control of the source as well as monitoring the process of production and continuous improvement. In the future we will continue to keep to the principle of quality first. We will continue to enhance the quality of our products and services to create greater value for customers.

Machine cnc machine company is manufacturing pipe processing automation equipment for more than 10 year and we have more than 1,000 designs that are not conventional. Once we have a complete understanding of the requirements of our clients and requirements, our experienced sales team can tailor the services to meet your needs. The project planning process is followed to manufacture and debug our equipment. Customers can watch the equipment assembly and debugging progress online anytime. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to ensure that the equipment is promptly incorporated into the customer's factory production tasks; We have a perfect data and equipment archiving system. The customer's equipment is preserved both in electronic and paper files. Mold updating can provide illustrations or Customization. After-sales support is provided by our experienced team.