Have you seen it big pipe? Pipes are long tubes used to transport things like water or gas from one location to another. They play such a huge role in our daily lives since they provide fresh water to our homes and carry gas for heating. However, we need to prepare these pipes in a manner before we can utilize them. This is where specialized equipment such as steel pipe double head chamfering machines come into play! That's why at Vedette we specialize in manufacturing and designing these machines, making the pipe preparation process faster and simpler. So, let’s dig deeper and discover how these machines operate!

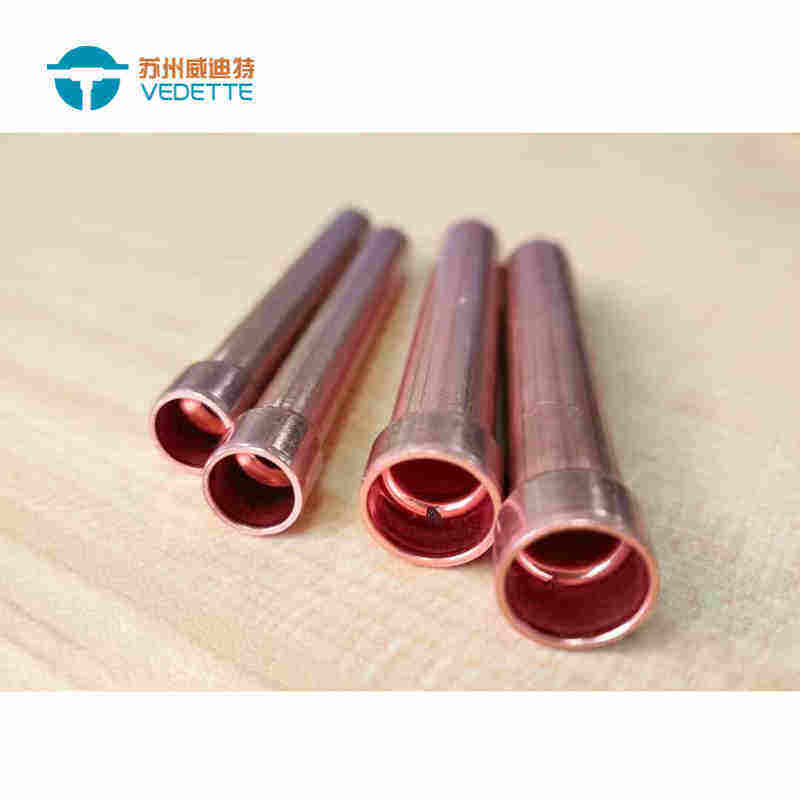

Pipes must be prepared properly before they can be used to build or move things. This involves trimming the pipe to the appropriate length and ensuring that the edges are smooth and clean. The non-smooth ends also make it difficult to match end of it with each other or with other pipes. Old school pipe cleaners can be time-consuming, and annoying, to use. But here comes the double head chamfering machines that can do this job extremely fast and neat, hassle free preparation of your pipes.

We have machines that have two heads, which means they can work on both sides of the pipe simultaneously. It can help tremendously, as it helps speed up the process and ensures that both end of the pipeline are shaped identically. The machines are also quite intelligent; they can adapt to various pipe sizes and shapes, meaning that they can be to multiple types of pipes, big and small. This kind of versatility is critical for workers, as they regularly work with different types of piping in their jobs.

Our machines are easy to use, meaning only one person needs to operate them, so they don't require much assistance. AND IT HAS SAFETY MEASURES BUILT IN TO KEEP THE USER SAFE WHILE USING THE MACHINE. C = These are extremely critical pieces of safety equipment through which many avoid accidents, keeping everyone safe. And our machines are low maintenance, which means they have longevity and operate well and without the need for constant repairs. This makes them a good investment for any business that handles pipes often.

With our edge chamfering machines, we ensure that both ends of the pipe are chamfered equally using the latest technology. This ensures that when the pipes are all connected they will interface properly and without issues. Many of the jobs that require a pipe involve the need for consistency, and our machines help ensure that the pipe does what it is intended to do.

Welding is an essential process in dozens of industries, and the quality of the weld hinges on how well the pipes are prepared beforehand. The ends of the pipes must be shaped properly; otherwise, the welded joint will be weak and will fail or leak sometime down the line. Which is why at Vedette, we ensure that our machines provide sufficient chamfering for strong and reliable welding.

The machines we operate are built with speed and efficiency in mind, allowing many pipes to be readied at once with high precision. This not only enables our customers to work better and maximize their profitability, but most of all, it makes our machines an ideal solution for any business whose pipe-preparation requirements are prone to frequent changes. With our machines, businesses can not only be more efficient, but also be more cost-effective.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. It is a top-quality national enterprise that has over 10 years of experience in research, development, manufacturing, and modifying automation production lines. As of Steel pipe double head chamfering machine it was the holder of 31 utility models and 10 patents on inventions of equipment. Its equipment is highly regarded both in China and abroad, with many customers.

We are your Steel pipe double head chamfering machine for equipment to process pipes offering a variety of equipment to fulfill your needs. We have been working on the field of automation equipment for pipe processing for over 10 years and are able to offer more than 1000 non-standard design patterns. After a thorough understanding of the customer's needs the experienced sales staff will tailor services. The planning process for projects is followed to manufacture and debug our equipment. The process of assembly and debugging can be viewed online by the customer at any point. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to make sure that the equipment is quickly integrated into the client's factory production processes. We have a flawless record of equipment and data. The information of the customer's equipment is preserved both in documents and in paper. Mold updating is a way to provide drawings or Customization. After-sales support is provided by our expert team.

Suzhou VEDETTE is a Steel pipe double head chamfering machine manufacturer of pipe processing equipment in the field. It places great emphasis on technological innovation, research and development, and launches new products that are competitive to meet the ever-changing needs of the marketplace. We believe in the quality of life and customer satisfaction as our primary goal, to provide you with a full range of professional services that include pre-sales consultation as well as sales technical support after-sales maintenance, to ensure that customers have access to of prompt and efficient technical support and solutions. Our products cover a wide application for the requirements of different industries in pipe processing. Suzhou VEDETTE, a renowned manufacturer of pipe processing equipment is the best choice for users.

To ensure stability and quality in product quality, we adhere to the concept of quality first as well as take other steps like Steel pipe double head chamfering machine of sources, monitoring the production process, and continual improvement. We will continue to adhere the quality-first principle in the near future, and will continue to improve our products and services in order to provide greater value to customers.