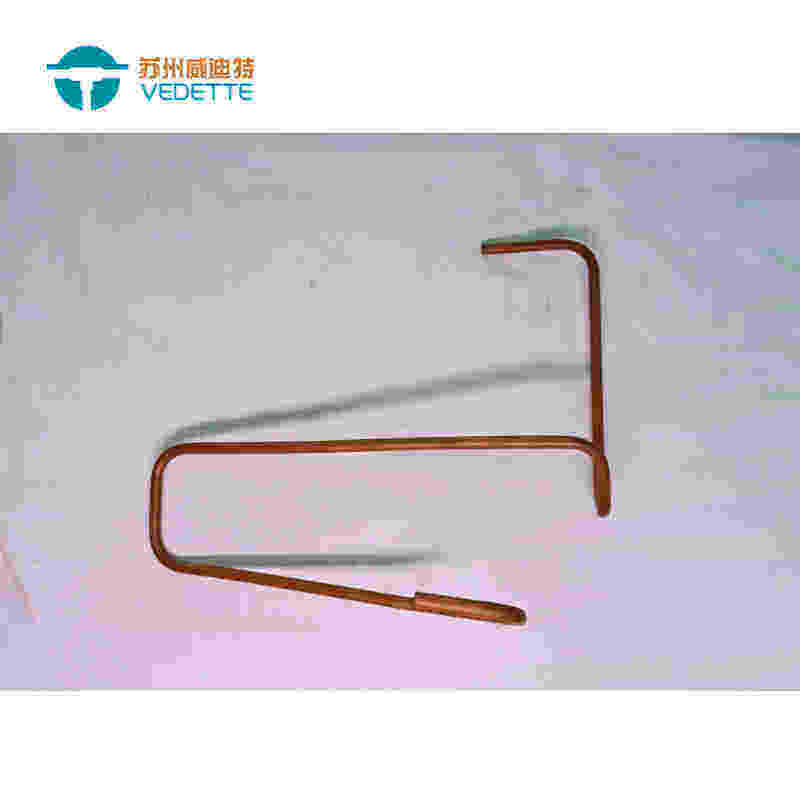

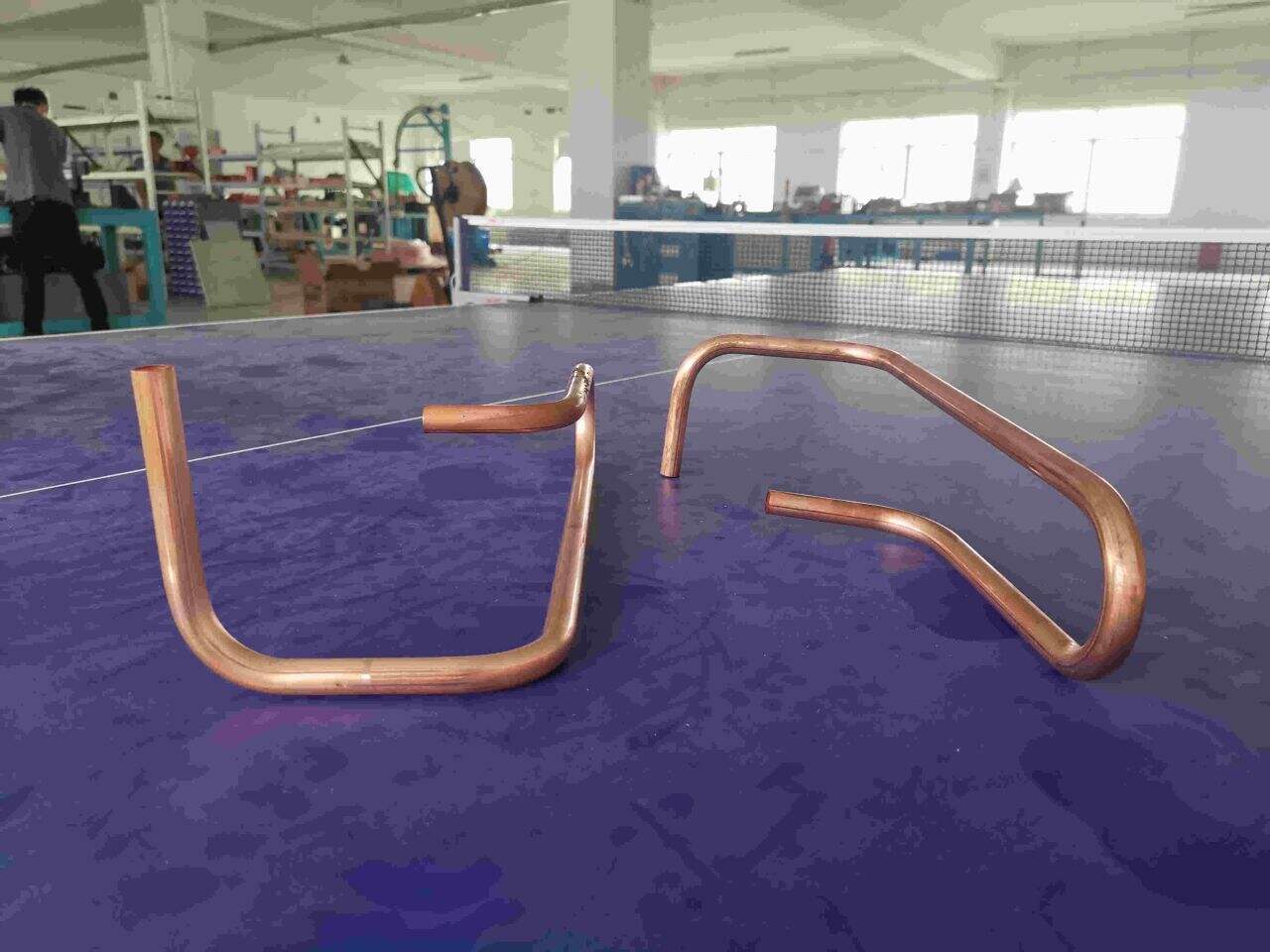

AWAD dataThis post may be expanded, improved and continued in the futureA 90 degree bent pipe is a specific type of pipe used for plumbing and machinery. This model includes a bend of 90 degree and is cultivated to suit for quick changes. This design helps to avoid the friction attack due to which liquids and gases flow smoothly without slowing down in pipes. The shape of the automatic steel pipe cutter is not a straight structure but sways, which can be an advantage in tight areas were a straight structure would design into not adding up

Also, a 90 degree bent pipe is used in the system to reduce the pressure and turbulence. This way the overall system works better with fewer hiccups in the flow. That means that the copper pipe tube bender and other components will not get worn out any time sooner, possibly saving from more repairs or replacements in the future

Step 2: The pipe will now have to be cut to size and at an angle. These measurements are really important, as you will need to be accurate with these when it comes down to actually getting the installation done, Clean the pipe and the area where you will install it properly before installing the pipe. A dry and clean surface ensures a nice seal, while preventing leakage.

Add the pipe where you want it, then secure it to its system using the fittings that are appropriate. All connections checked and tightened for zero leaks. Loose connections to the hard copper pipe bender can cause problems, and if left unresolved, could damage or lead to loss of the fluid — or gas flowing through the line.

There are many factors related to the selection of material. You should start with what kind of liquid or gas will carry through the pipe. Not all substances are good for each material and conversely. Next, consider the system pressure and temperature. Different materials also can have greater strength at higher pressures and temperatures. Last, but not the least, it is highly important that you see to it as to exactly where the pipe will be place. If it will be outdoors, for example, then you might look at weather-resistant materials.

To correct that, the solution ranges from identifying where the issue is coming from. This could be as simple as looking heat the outside of the pipe or maybe inspecting half to make it once getting damaged or if there was a lot of build-up causing an obstruction. Finally, when you get to the bottom of your problem, you can fix it properly.

Our company is manufacturing pipe processing automation equipment for more than 10 year and we have over 1,000 design schemes that are not standard. 90 degree bent pipe sales teams can customize services based on a thorough understanding of customer demands. The process of planning the project is followed to manufacture and test our equipment. Customers can follow the equipment's construction and debugging progress on the internet anytime. They will conduct an exit inspection following the strict process for delivering the exit after the equipment has been accepted to ensure the equipment can be quickly integrated into the factory production processes of the customer. We have an archive system for data and equipment system that is flawless. The customer's data equipment is saved both in the form of paper and electronic files. The mold updating service could be used to provide drawings or Customization. After-sales assistance is provided by our expert team.

We have always 90 degree bent pipe high-quality as the primary objective by ensuring that we control the source monitoring of production processes, continuous improvement and other measures to ensure the highest quality and consistency of the quality of our products. We will keep adhering to this principle in the near future, and will continue to improve our products and services in order to offer greater value to our customers.

Suzhou VEDETTE is a leading 90 degree bent pipe of pipe processing equipment in the field. It places great emphasis on technological innovation, research as well as development, and has launched new products that are competitive to meet the ever-changing demands of the market. We're committed to provide you with expert solutions that include pre-sales consulting as well as sales technical assistance and after-sales support. This ensures that our customers get prompt and efficient solutions. Our products are broadly applicable to different industries. Suzhou VEDETTE which is a major manufacturer of equipment for pipe processing is the best choice for users.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the manufacturing of equipment. With over a decade of expertise in the development, research and manufacturing of tube processing equipment as well as different types of custom-designed automation production lines, it is a national high-tech company that is involved in the design and manufacture of technologically automated and sophisticated equipment. As as of December 20, 2022, it had 31 utility model patents, and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, serving clients across the world. The company adheres to its corporate goal of offering quality products and services that add value to customers, and is committed to becoming a pioneer in the field of technological advancement for tube processing equipment within 90 degree bent pipe.