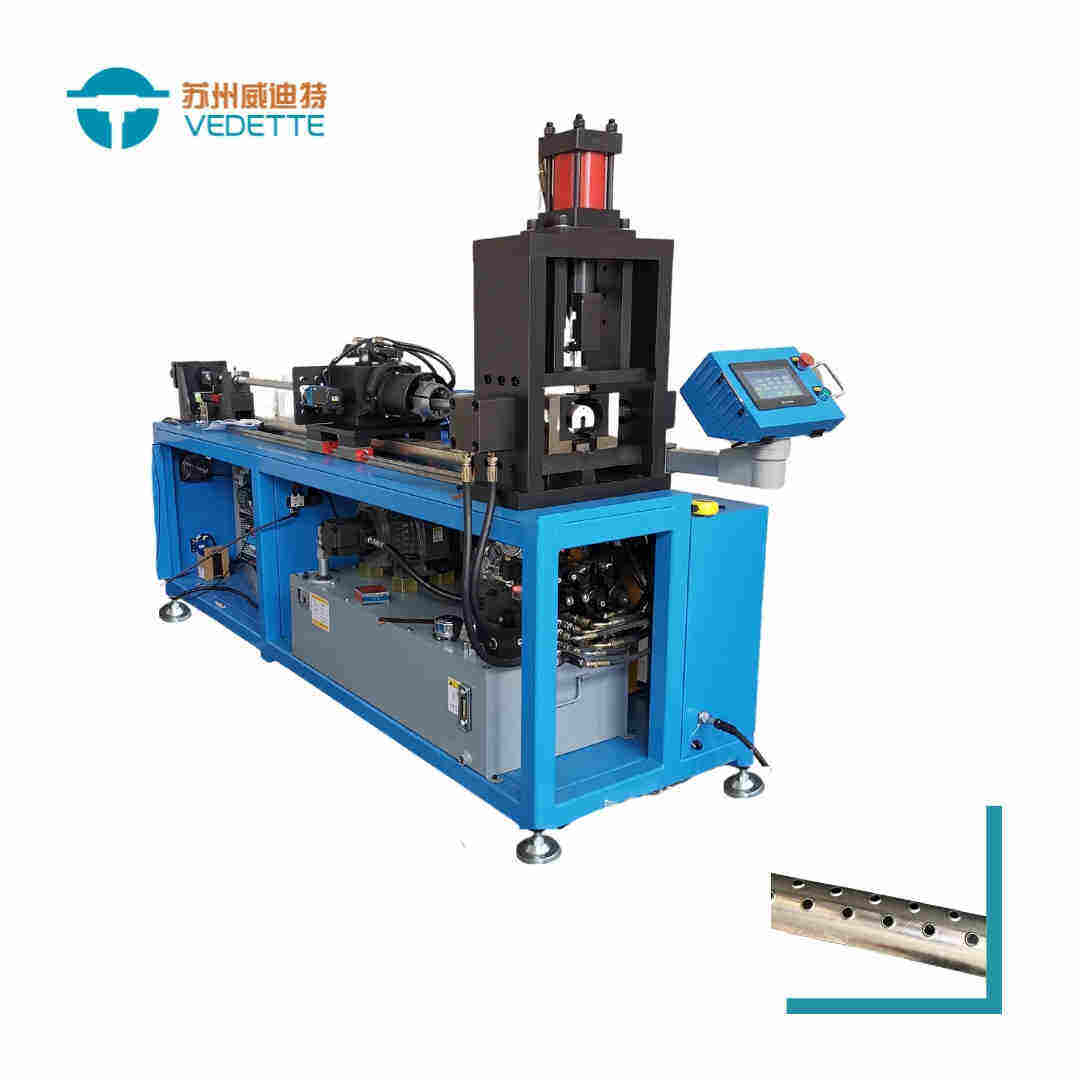

Are you familiar with a CNC metal punching machine? A powerful and heavy-duty machine that is capable of producing metal parts quickly–and with a lot of precision. CNC stands for Computer Numerical Control that is a kind of operation available and allowed in case the computer implementation directives are provided (but not necessarily used). This way, the machine could be programmed to punch designs of different shapes into sheets of metal which becomes very accurate at cutting and designing.

Also it is possible to own a CNC metal Vedette Punching machine, in which case the speed has gone up considerably and you will cut fewer mistakes. Designed to work with metal but could possibly perform on other substances, like plastics OR the penile rectum habitat. Its flexibility makes it handy for a ton of different projects.

Gone are the days when you would see machines outworking humans? As it was designed to work rapidly, this machine will do. Well it is only too common and needless to mention a CNC metal punching machine stands not as an exception. It is designed to do what it does fast and effectively.

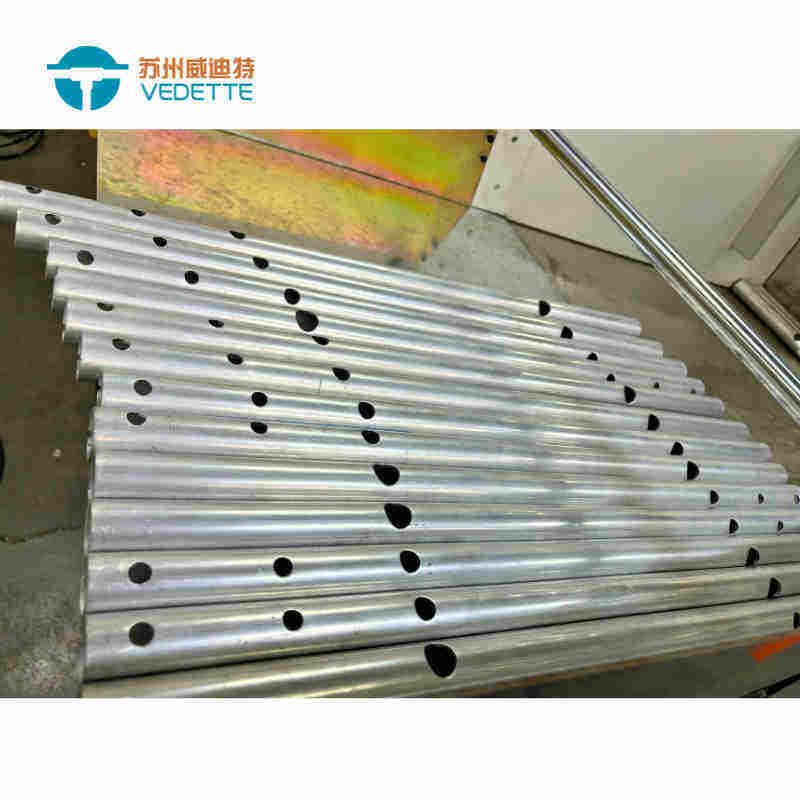

It adheres to several patterns it was provided with according to design which makes the machine hit about every stroke very fast and puncture metal pieces across each of them highly accurately. This allows for organizations to build metal pieces that are not only the same size, but also identical in shape every time they use a machine. For manufacturing, too it is easier and helps save time as well as money when all things are the same.

Do you have any idea how many hours a Metal Punching Machine CNC can work in one single day? It is, because Vedette single-shaft punching machine does not get tired of working as easily as humans do. Which means there is no need to power it down ever as with humans that operate on a continual cycle of productivity met by rest.

CNC punching machine is one of the most essential type’s tools in metal shop. You could program Vedette Punching and pulling machine to bend metal sheets into certain shapes, which allows for the creation of goods like auto parts and tools or electronics. But don’t worry this is good as you create unique designs and business likes it.

Using a CNC metal punching machine is going to help you make more items and therefore it will allow for an easier production process that in turn effect the quality of your product. It is also a great opportunity to stay competitive in the world of manufacturing. If companies are able to use such technologies, they could potentially not just meet client expectations but also stay ahead of the market requirements.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in southwest Suzhou in close proximity to Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a highly-tech national company with more than a decade's experience in research, development, manufacturing, and customizing automation production lines. At the time of its December 2022 launch, it was the holder of 31 utility models and 10 patents on inventions of equipment. The equipment it produces is highly Cnc metal punching machine both in China and around the world, with numerous customers.

We Cnc metal punching machine adhere to the quality as the core by ensuring that we control the source, production process monitoring and continuous improvement as well as other methods, to ensure the excellence and reliability of the product. We will keep adhering to the quality-first principle into the future and improve our products and services in order to offer greater value to our customers.

We are your Cnc metal punching machine for equipment to process pipes offering a variety of equipment to fulfill your needs. We have been working on the field of automation equipment for pipe processing for over 10 years and are able to offer more than 1000 non-standard design patterns. After a thorough understanding of the customer's needs the experienced sales staff will tailor services. The planning process for projects is followed to manufacture and debug our equipment. The process of assembly and debugging can be viewed online by the customer at any point. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to make sure that the equipment is quickly integrated into the client's factory production processes. We have a flawless record of equipment and data. The information of the customer's equipment is preserved both in documents and in paper. Mold updating is a way to provide drawings or Customization. After-sales support is provided by our expert team.

Suzhou VEDETTE, as a Cnc metal punching machine manufacturer of pipe processing equipment in the market, puts an immense importance to technological advancement and research and development investment and is constantly launching new products with market competitiveness to meet the ever-changing demands of the market. We are committed to quality of life, customer experience as our main goal, to provide you with a full range of professional services including pre-sales support as well as sales technical support after-sales support, to make sure that customers have access to of prompt and efficient technical assistance and solutions. Our products offer a broad application to meet the demands of different industries in pipe processing. For the users who need pipe processing equipment Suzhou VEDETTE is an ideal choice.