CNC Press Brake Machine — What It Is And How It Works It is a unique type of machine that was created to help in bending metal sheets into different desired shapes and forms. These are really very important machines in metalworking. Throughout history, before the invention of CNC press brake machines people had to bend metal with their hands. It was a necessary but onerous process that inevitably led to errors. A process that might take a really long time for just one piece of metal to turn into right shape. It is only now that we have a better, quicker method to bend metal easily by the virtue of 40 CNC pipe bender from Vedette.

Also, these machines work very fast. It was quite time-consuming to bend metal by hand, which had an impact on production lead times. It is a rapid process when you utilize CNC press brake machines because often the machine do most of it automatically. This 13 CNC pipe bender from Vedette helps them bend more metal, faster, allowing businesses to get through their projects and make those important deadlines.

Features of CNC press brake machinesThe special features in a cnc hydraulic press brakes for sale which makes it even more productive. Automatic tool changer is an important feature. What this means is that the machine can automatically exchange tools itself without an operator. It saves time and minimizes the possibility of bending errors. There is another feature that allows you to fold several pieces of metal at a go using 20 CNC pipe benders from Vedette. Contrarily with a Press Brake, you would have to bend them one at the time; on these machines, it is possible to make several bends simultaneously. This means more metal can be bent in the same amount of time, leading to increased efficiency for businesses.

Selecting the best CNC press brake machine for your production requirements. We have a couple of factors to take into account when deciding. Again, with too small a bed you will find that you are simply unable to work at all or certainly not easily with some larger pieces of metal. Choose 30 CNC pipe bender.

Another thing to take into account is the tonnage of your machine. Tonnage: This refers to the amount of pressure that machine can apply on metal sheet and is called as TON. You have to select Pipe bending machine according your bending Operation Thickness as only tonnage is the thing that can damage you Metal Sheet. Insufficient tonnage will hinder the ability to generate desired bends, resulting in poor work.

To ensure consistency and excellence in the quality of our products, we Cnc press brake machine to the concept of quality first as well as take other steps such as source control, monitoring the production process as well as continuous improvement. We will keep adhering to this principle in the near future, and will continue to improve our services and products to offer greater value to our customers.

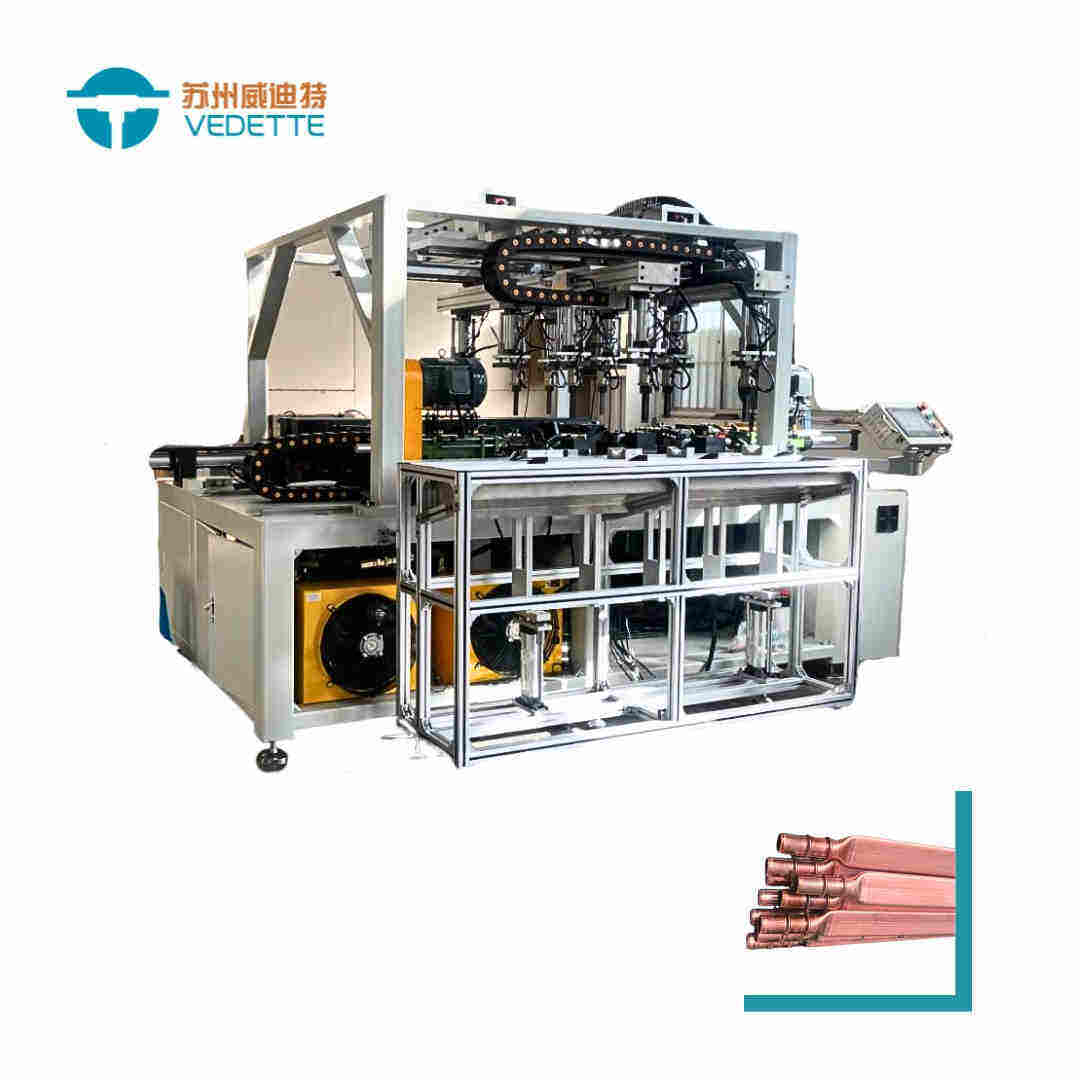

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the manufacturing of equipment. With over a decade of expertise in the development, research and manufacturing of tube processing equipment as well as different types of custom-designed automation production lines, it is a national high-tech company that is involved in the design and manufacture of technologically automated and sophisticated equipment. As as of December 20, 2022, it had 31 utility model patents, and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, serving clients across the world. The company adheres to its corporate goal of offering quality products and services that add value to customers, and is committed to becoming a pioneer in the field of technological advancement for tube processing equipment within Cnc press brake machine.

Suzhou VEDETTE is a leading producer of pipe processing equipment for the field. It is a Cnc press brake machine on research and development, and also launches new products that are competitive to meet the ever-changing needs of the marketplace. We place quality of life and customer experience as our main goal, to provide you with the full spectrum of professional solutions that cover pre-sales advice as well as sales technical support after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products cover a wide variety of application options for the requirements of various industries that require pipe processing. Suzhou VEDETTE, a leading manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.

Our company has been manufacturing pipeline processing automation equipment for more than 10 year and we have over 1000 designs that are not typical. Experienced sales projects will customize services based on a thorough understanding of the needs of customers. Our equipment is designed and tested according to the project design process. Customers can follow the equipment's assembly and debugging process online anytime. When the equipment is approved, they will carry out the inspection of exit in line with the process of exit delivery to ensure that the equipment can be swiftly integrated into the customer's factory production processes. We have a flawless storage system for data and equipment. All Cnc press brake machine about equipment and customers are preserved in paper files and electronic files. The mold updating service could be used to draw sketches or custom. After-sales assistance is provided by our team of experts.