These tube punching machines are super awesome tools! They can assist in many ways and facilitate various tasks. Here at Vedette, we think that punching machines are amazing, and we want to tell you all we know about them.

Punching machine is a specialerrific tool per se that is used to forms holes or shapes in them material paper, metal or plastic. It consists of two major components, a die and a punch. These pieces push against each other, and cut out the shape you desire as they move into alignment. And there are multiple variations of over punching machines. Some are small and use handheld, others are big and machine-powered. People can easily select the proper punching machine according to their needs; either for a home-based enterprise that can fulfil or a factory-based enterprise that can support huge production.

Punching machine oriented jobs অনেক জব এর জন্য খুব বেশি ভাবে জরুরি. They’re used for industrial and commercial purposes, including manufacturing, printing, and construction. These machines allow workers to quickly cut exact holes and shapes, ensuring accuracy and precision. This efficiency helps businesses save time and money. There are tube punching equipments of all shapes and sizes. Some fit in your hand, others are big contraptions in massive factories, producing thousands of products at a time. The versatility means that there is a punching machine for nearly every job!

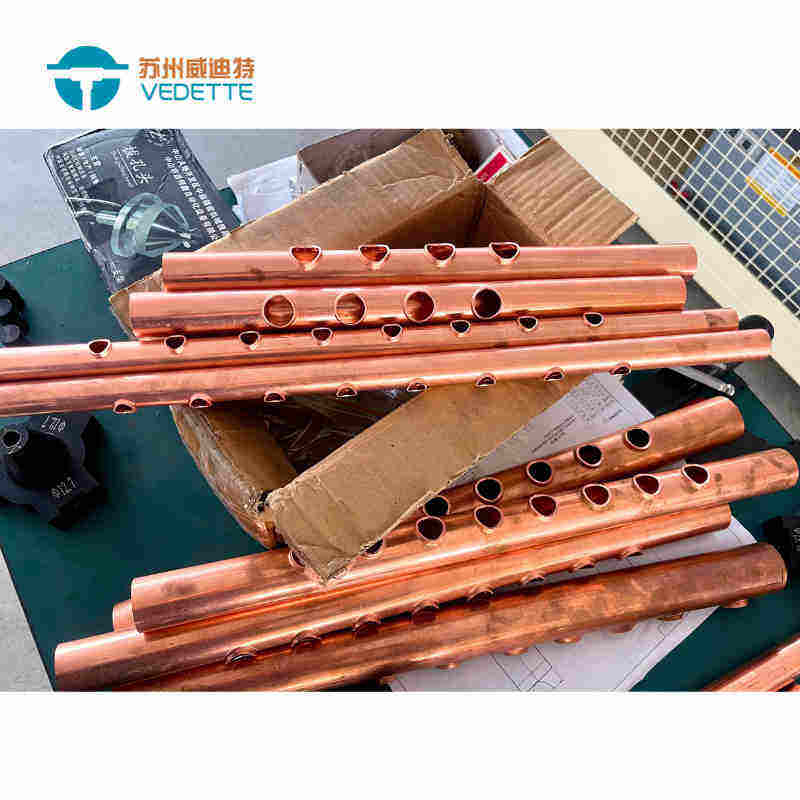

The good thing about punching machines is that they can perform various jobs. They can also punch holes of different shapes and sizes. This makes them extremely useful for a variety of tasks. Some punching machines can even make holes in special shapes, like the round holes on binders to hold the pages together. Another thing they can do is make designs on paper that are raised or pressed in, which adds a a truly unique and special appearance to the final product. This versatility gives punching machines great utility across many types of creative projects.

Punching machines will enable companies to work faster by performing repetitive tasks. In a factory, for instance, workers may punch holes in metal sheets using punching machines. These holes are commonly necessary for constructing air conditioning units or other products. While the punching machine is doing its work, the employees can concentrate on the other meaningful work that needs more attention. This enables businesses to create more products in a shorter amount of time and with less exertion. Businesses are able to cut costs and be more productive thanks to punching machines.

12 Benefits of Punching Machines for Different Industrial Applications They save time, lower costs and increase workers’ productivity on the job. Moreover, punching machines are also simple to use, so a lot of individuals decide to utilize punching machines price for their plans. Punching machines are a must whether it is small home projects or big industries.

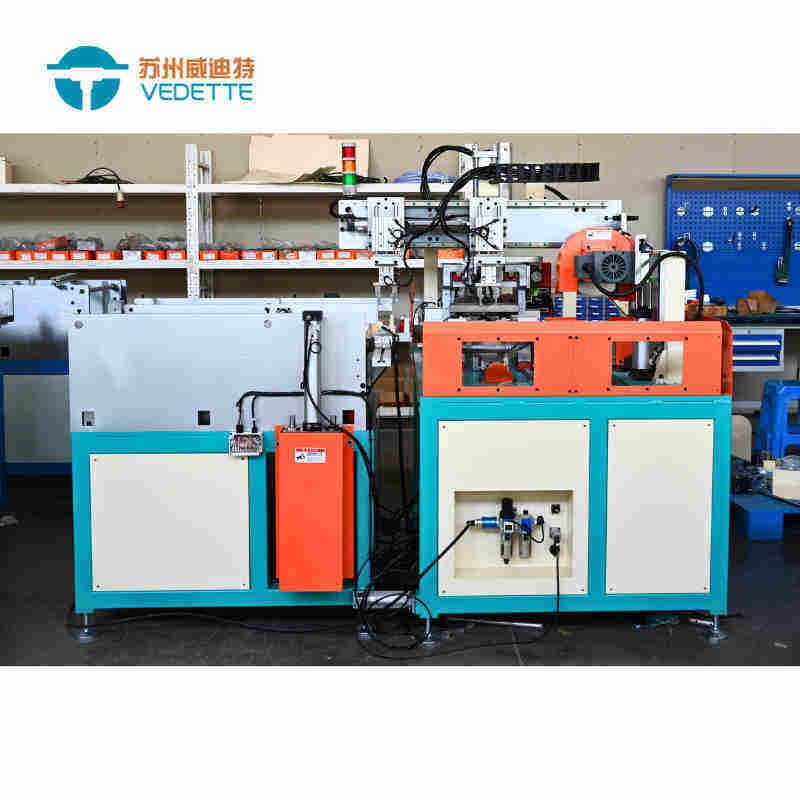

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the punching machine. It puts a lot of emphasis on technological innovation, research as well as development, and has launched new products that are competitive in keeping up with the changing needs of the market. We place quality of life, as well as the customer experience as the core of our business, and offer the full spectrum of professional services that include pre-sales consultation and technical support for sales, after-sales support, to make sure that customers get the benefit of professional and timely technical support and solutions. Our products have a wide selection of applications to meet the needs of different industries in pipe processing. Suzhou VEDETTE, a leading manufacturer of equipment for pipe processing is the best option for users.

To ensure stability and quality in product quality, we adhere to the concept of quality first as well as take other steps like punching machine of sources, monitoring the production process, and continual improvement. We will continue to adhere the quality-first principle in the near future, and will continue to improve our products and services in order to provide greater value to customers.

We are the one-stop supplier for equipment to process pipes providing a range of equipment to meet your needs. We are focusing on the field of pipe processing automation equipment since more than 10 years and are able to offer more than 1,000 non-standard design schemes. Experienced sales projects will customize services following a thorough analysis of customer demands. Our equipment is produced and developed according to the punching machine. The process of assembly and debugging can be seen online by customers at any time. They will conduct an exit inspection strictly in line with the process for delivering the exit once the equipment is accepted so that the equipment can be quickly integrated into the factory production tasks of the customer. We have an archive system for data and equipment system that is completely reliable. All equipment information of customers is preserved in paper files and electronic files. Mold updating can provide illustrations or Customization. After-sales services are provided by our professional team.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the manufacturing of equipment. With over a decade of expertise in the development, research and manufacturing of tube processing equipment as well as different types of custom-designed automation production lines, it is a national high-tech company that is involved in the design and manufacture of technologically automated and sophisticated equipment. As as of December 20, 2022, it had 31 utility model patents, and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, serving clients across the world. The company adheres to its corporate goal of offering quality products and services that add value to customers, and is committed to becoming a pioneer in the field of technological advancement for tube processing equipment within punching machine.