In modern manufacturing, which prioritizes efficiency and precision, traditional pipe cutting methods often suffer from problems such as flying debris, burrs, and material waste.

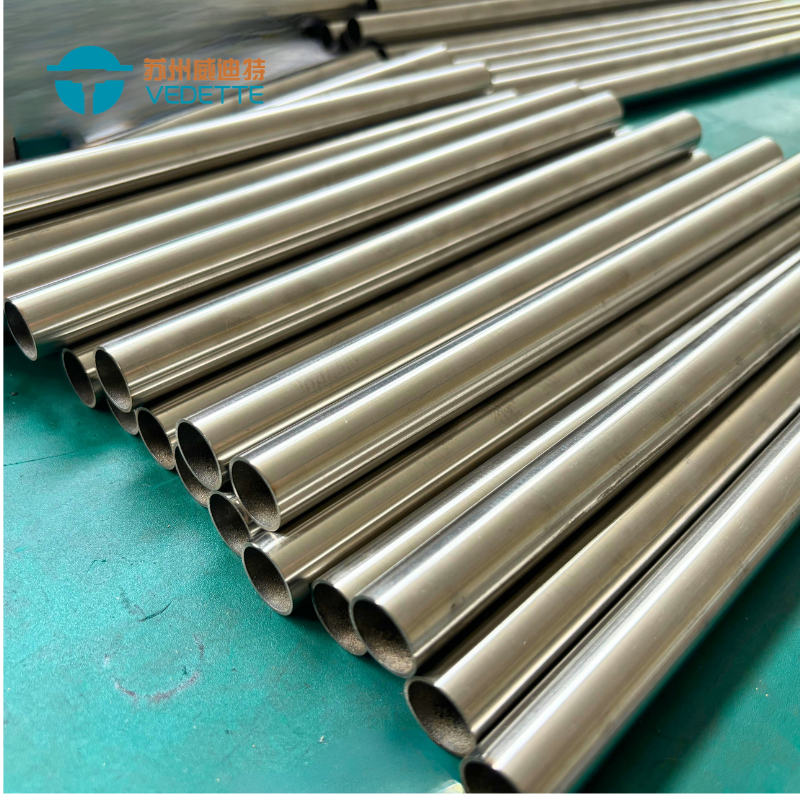

Suzhou Vedette CNC burr-free pipe cutting machine is specifically designed for the precision cutting of various metal pipes, including copper, aluminum, iron, and stainless steel, leading the way to a new era of clean and efficient cutting.

Core Technological Advantages: Burr-free, high-quality results in one step

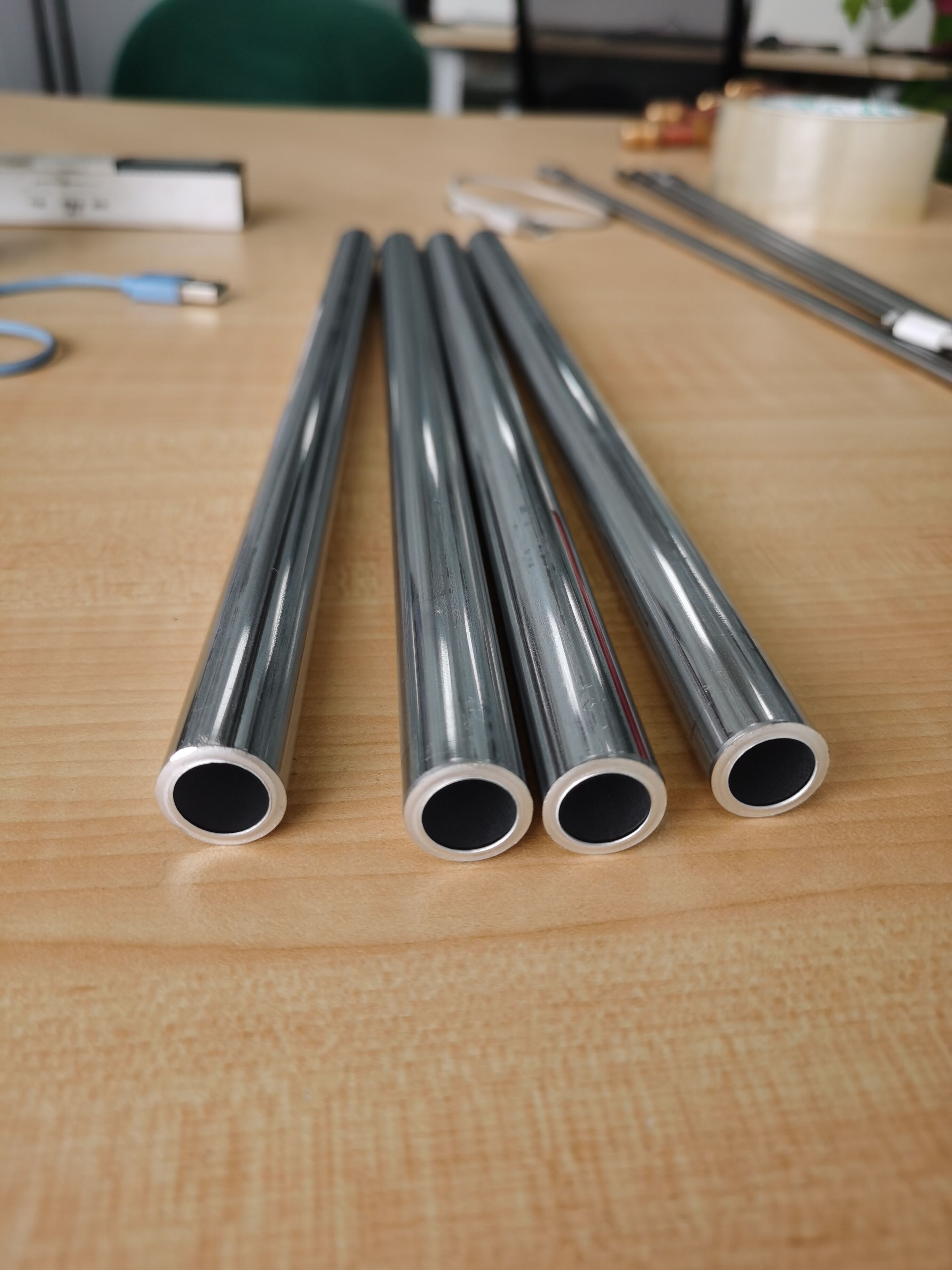

This equipment utilizes advanced burr-free cutting technology, completely eliminating the flying debris generated by traditional sawing and turning. Its unique rotary extrusion cutting principle completes the end sealing and shaping of the pipe in an instant, achieving:

Smooth and flat cutting surface: The ends are burr-free and undeformed, allowing for direct entry into the next process (such as welding and assembly), saving the trouble and cost of secondary processing.

Zero waste generation: Maintains an extremely clean working environment, reduces material waste, and lowers cleaning and recycling costs.

High efficiency and low energy consumption: Fast cutting speed, no coolant required, energy-saving and environmentally friendly, significantly improving production efficiency.

Intelligent CNC System: Precise and flexible, production on demand

The equipment is equipped with a high-performance CNC (Computer Numerical Control) system with an intuitive and user-friendly operation interface.

Precise settings: Cutting length, quantity, and speed can be precisely set, ensuring that the cutting accuracy of each pipe is highly consistent, perfectly meeting the requirements of precision assembly.

Flexible response: Particularly suitable for multi-batch, small-batch, and diversified production needs. You only need to adjust the parameters in the system to quickly switch production tasks and achieve flexible production.

Customized Solutions: Your needs, our design standards

We understand that the processing needs of different industries and different customers vary greatly. Therefore, we provide in-depth customized services:

Pipe diameter and material: The equipment can be adjusted and enhanced according to your required pipe diameter range, wall thickness, and special materials.

Automation integration: It can be equipped with automatic loading racks, feeding systems, and finished product collectors to create a fully automated production line. Machine models can be customized according to production needs - single pipe, double pipe, 4-pipe, 6-pipe, and 8-pipe models are all available. Wide range of applications:

Heat exchangers (condensers and evaporators), electrical appliances involving heat exchange, such as refrigerators, water heaters, air conditioners, heat pumps, and heat pipes, and other industries that use copper tubing components. It excels in any application requiring efficient, clean, and precise cutting of metal tubing!

Hot News

Hot News2025-11-26

2024-02-26

2024-02-26

2023-04-10

2015-06-02

2015-05-06