Pipe end forming is very critical in piping systems where pipes are connected together. This post discuss most common type of pipe end forming and why it is important starts with what the heck is a pipe end forming? We will then cover various ways of accomplishing pipe end forming and how learning them can create reliable connections. We will also examine some common issues one might face while doing so and how those can be relieved using new technology. Vedette Stainless steel pipe punching machine is a great company providing pipe end forming solutions for quite a few different industries, high-quality guaranteed.

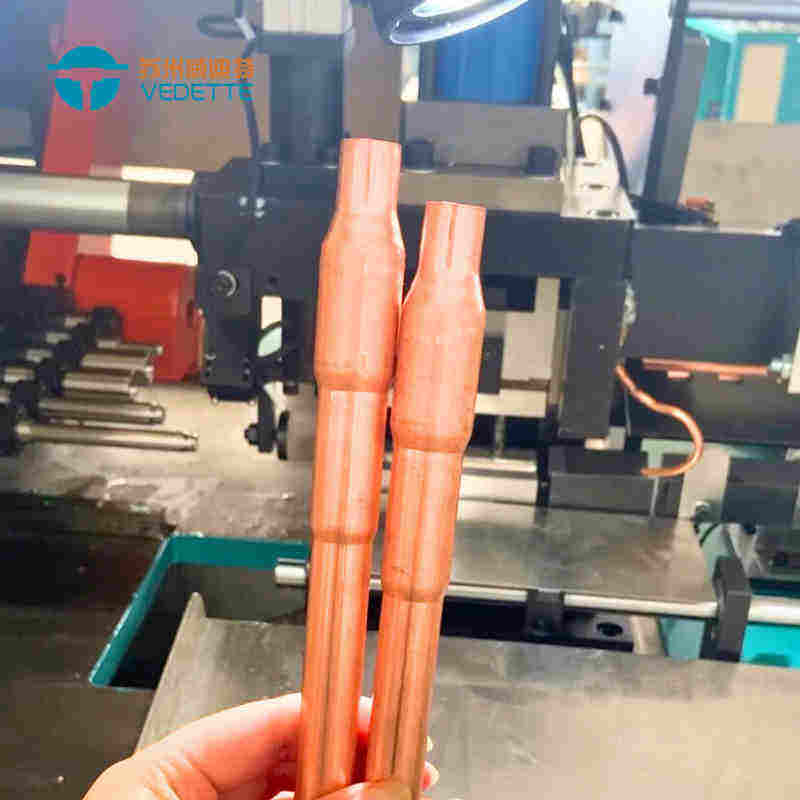

Pipe End Forming — A process that changes a shape of an end of tube or pipe so it can fit with other pipe or part. This is a key in many different areas including plumbing, cars, airplanes and construction. Any misfit with the ends of the pipes can cause a leak or more trouble to fix. The pipe end may be shaped in different manners the pipe the end shape is forged. Common methods of shaping are flanging (shaping a metal piece radically), beading (making the end of a sheet or pipe with a raised edge), grooving, swaging (reducing diameter via forcing center into an annular gap) and these are used to form the locks made from military grade stainless steel. Each of these tactics is used for a unique purpose and in different circumstances.

Pipe end forming can be done in a number of ways, and every method will require a particular set of tools and equipment. The way is to use that of tanks, for instance flaking and uvula, most often pairing the tubes are not same size, than seem as two different pipe lines: a drums come suit each other. Expanding / reducing methods, on the other hand are used to adjust the size of opposite end of the pipe for it easier to connected to other fittings. Each of the above can also be applied by Vedette straight pipe cutting machine with good practicing, which in turn, gives a large scope for pipe end forming to their customers. They can make sure the links are strong and dependable, by utilizing suitable procedure for each case.

Pipe end forming is a critical task that should be accomplished with zeal and accuracy. The pipe termination has two portions which must be molded together to give the connection a static form.

If pipe ends are not properly fitted, it may lead to leakage or the entire piping system becomes weak. That is precisely why precision matters. Finally, Vedette employs first-rate tools and makes sure the work is adequately inspected. The Vedette Pipe bending machine are meticulous about ensuring everything fits perfectly whenever possible, because this assures little or no trouble later on.

There are many things that can go wrong with pipe end forming, which means it is not always easy to accomplish. The outcomes can vary, as well, based on the type of material that is used in making them, how thick the pipe is made and what environment work-in-progress has been. Wrinkling, bending, cracking or mismatches in size are some common issues. If not addressed, such problems have the potential to lead to delays and additional expenses. Vedette provides customer-oriented solutions to address these issues, and the company collaborates with its customers to identify possible issues experienced by their clients. It allows them to offer the best service possible by knowing exactly what each project might require.

New pipe end forming technology is one of the few innovations that can improve piping systems in a number of ways. This optimizes the process and depending on the job it can be faster, stronger and ultimately cheaper in some cases in the long run. This helps with better fitting of pipe ends and reduces errors due to use of advanced technology. It ultimately extends the life-span of the piping system when those joints are made correctly. When customers work with Vedette, they are able to benefit from the latest industry innovations in pipe end forming tools and technologies. With this kind of partnership they can make better, and tougher piping systems that performed well over time.

Suzhou VEDETTE, as a leading Pipe end forming manufacturer in the market, puts the highest importance to technological innovation and investment in research and development, and continues to launch new products that compete to meet the increasingly diversified requirements of the market. We adhere to the quality of life, customer satisfaction as the primary objective and provide all the professional services covering pre-sales consulting, sales technical support, after-sales service, and ensuring that customers get the benefit of timely and professional technical assistance and solutions. Our products can be applied to a variety of industries. Suzhou VEDETTE which is a major manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the manufacturing of equipment. With over a decade of expertise in the development, research and manufacturing of tube processing equipment as well as different types of custom-designed automation production lines, it is a national high-tech company that is involved in the design and manufacture of technologically automated and sophisticated equipment. As as of December 20, 2022, it had 31 utility model patents, and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, serving clients across the world. The company adheres to its corporate goal of offering quality products and services that add value to customers, and is committed to becoming a pioneer in the field of technological advancement for tube processing equipment within Pipe end forming.

We are the one-stop supplier for pipe processing equipment, offering a range of Pipe end forming to satisfy your needs. We have been working on the field of automation equipment for pipe processing since more than 10 years, and have over 1,000 design concepts that are not standard. Our sales professionals are experienced and can tailor solutions based on an in-depth understanding of the needs of customers. Our equipment is designed and debugged according to the project plan. The process of assembly and debugging can be seen online by the customer at any time. Once the equipment is accepted by the customer, they'll conduct an the exit inspection in accordance with the process of exit delivery to ensure that the equipment can be promptly incorporated into the customer's factory production processes. We have an efficient data and equipment archiving system. The customer's data equipment is preserved both in documents and in paper. Mold updating can provide sketches or custom. We have a knowledgeable service department after sales and can provide after-sales cleaning and maintenance.

We Pipe end forming adhere to the quality as the core by ensuring that we control the source, production process monitoring and continuous improvement as well as other methods, to ensure the excellence and reliability of the product. We will keep adhering to the quality-first principle into the future and improve our products and services in order to offer greater value to our customers.