Ever seen how pipes are created? While fingertipping may seem simple enough to do, it does take a good deal of skill and knowledge to do it well. We use pipes in various ways, including plumbing in houses and the construction, such as bridges and buildings. When you have to work with Vedette copper pipe cutting mac, it usually means that they need cutting and shaping in order to mesh correctly where they are needed.

When you are working on any job, it is important that you get the work done as quickly and efficiently as possible; pipe processing is no different. If you want to help, make dealing with piping systems smoother, here are the methods of working with pipes efficiently. Know your Vedette copper pipe cutting mac size and shape before you start have everything you need organized neatly so that you can find what you are looking for quickly.

There are a few good practices that fall kind of in between data structures and methods you can use to get the most when dealing with them. To start off, always keep in mind the old saying “measure twice, cut once. Therefore, get out a measuring tape and take time to carefully measure the Vedette steel pipe cutting machine before you start making any cuts. It will prevent you from committing errors that could ruin materials. Second, A guide helps you cut the pipe straight which is rather crucial for making pipes fit correctly.

Using pipes in a smart way ensures that the code is concise as well as performs well. Well, here are the tabs that you must close. One, do something in an orderly way This implies entail numerous orderly operations, cutting, twisting, and threading the channels within a systematic manner. It will help you to keep clean and smart. Second, work smart. Use the right approach and Vedette steel pipe cutting machine and do not forget about rest.

This job is not only about getting the work done as fast as possible, but also doing a good enough job that you can hang your hat on. Follow these necessary procedures for excellent results. Use high-quality pipes in the first place. Always consider Vedette automatic steel pipe cutter, a very strong and durable pipe that is also the appropriate size for your job; Second: comply with instructions that accompanied your tools and materials.

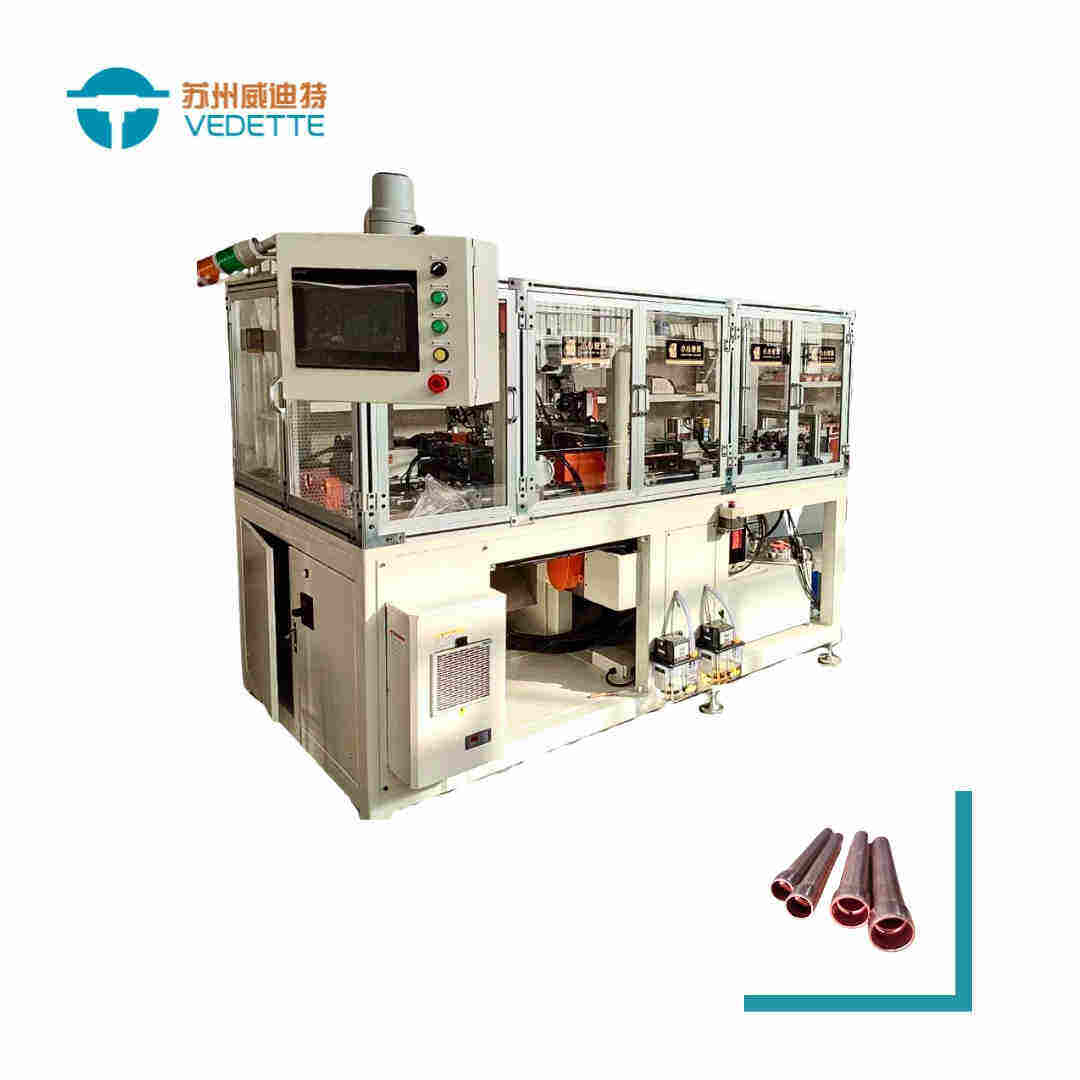

Pipe processing company is manufacturing pipe processing automation equipment for more than 10 year and we have more than 1,000 designs that are not conventional. Once we have a complete understanding of the requirements of our clients and requirements, our experienced sales team can tailor the services to meet your needs. The project planning process is followed to manufacture and debug our equipment. Customers can watch the equipment assembly and debugging progress online anytime. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to ensure that the equipment is promptly incorporated into the customer's factory production tasks; We have a perfect data and equipment archiving system. The customer's equipment is preserved both in electronic and paper files. Mold updating can provide illustrations or Customization. After-sales support is provided by our experienced team.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in southwest Suzhou in close proximity to Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a highly-tech national company with more than a decade's experience in research, development, manufacturing, and customizing automation production lines. At the time of its December 2022 launch, it was the holder of 31 utility models and 10 patents on inventions of equipment. The equipment it produces is highly Pipe processing both in China and around the world, with numerous customers.

To ensure stability and quality in product quality We adhere to the principle of quality first, and take other measures like source control, Pipe processing the production process and constant improvement. In the future, we will continue to stick to the principles of quality first, constantly improve the level of products and services to bring more value to our customers.

Suzhou VEDETTE is a leading Pipe processing of pipe processing equipment in the field. It places great emphasis on technological innovation, research as well as development, and has launched new products that are competitive to meet the ever-changing demands of the market. We're committed to provide you with expert solutions that include pre-sales consulting as well as sales technical assistance and after-sales support. This ensures that our customers get prompt and efficient solutions. Our products are broadly applicable to different industries. Suzhou VEDETTE which is a major manufacturer of equipment for pipe processing is the best choice for users.