We are thrilled to present out new pipe bending machine that utilizes the unique technology CNC. This incredible technology has completely revolutionised our approach to metal pipe production. CNC stands for "computer numerical control. “ This means that the movements of the machine are aided in some way by computers. This is a crucial innovation for us because it allows us to create metal pipes accurately and quickly.

Today, we turn to an innovation that is revolutionizing the pipe manufacturing process in factories: our CNC technology. The old way to make pipes was by hand, which was slow and expensive. It was a long and tiring process, as individuals used both their hands and tools to form the pipes. Our new CNC technology enables us to bend and form metal pipes in minutes, with significantly lower physical effort. This allows us to save a lot of time and costs, which leads our customers getting their orders much faster.

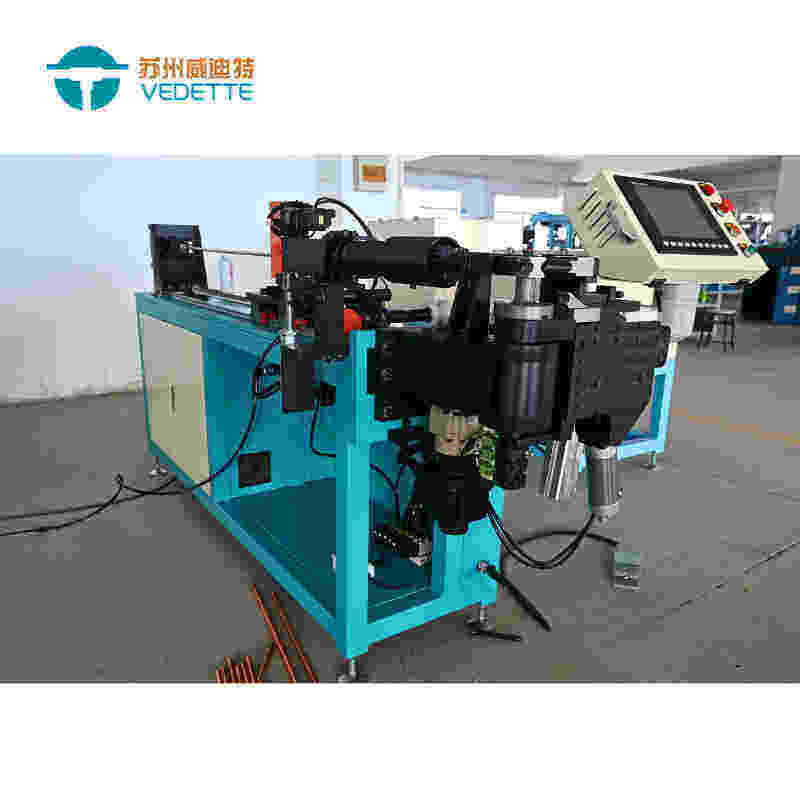

This CNC pipe bending machine is one of our best assistant tools to bend the metal pipes with the desired geometry. This machine takes precise measurements to ensure that pipes are bent at all of the exact angles we want. It means we can create pipes that are identical regardless of how many you produce. Our CNC technology allows us to work quickly and accurately, which is important when we have to manufacture a lot of pipes at once. This is quite beneficial for companies that require multiple pipes for their projects.

However, with the help of our CNC technology we have greatly improved the process for making pipes. Before the introduction of this technology, pipes were made by hand and often resulted in discrepancies in quality. At times, the pipes would appear altered or fail to fit together properly. Now, thanks to our CNC technology make sure the shape each pipe we made same with one another. Increasing production capacity of our Pipe Production Line using advanced technology to manufacture large quantities of pipes in a short time is the need for businesses who order many pipes at one time.

We also have a team of pipe benders using our automated machines that help us work more efficiently while eliminating the need for people to do it all by hand. The technology enables the complete automation process of making pipes which saves our time and money. We are very accurate with machines, which means that we can make pipes of uniform quality and size. This highly automatable process allows us to work much smarter, a huge bonus for businesses that require large numbers of pipes in rapid succession.

We are the one-stop supplier for pipe bending machine cnc, offering a variety of equipment to satisfy your needs. We have been working in the field of automation for pipe processing equipment for more than 10 years, and have over 1,000 designs that aren't standard. Our sales professionals are experienced and can tailor services after detailed understanding of customer demands. Our equipment is designed and tested according to the project plan. Customers can monitor the equipment's assembly and debugging progress online at any time. They will conduct an inspection at the exit point in strict compliance with the departure delivery process once the equipment is approved to ensure that the equipment can be quickly integrated into the factory production processes of the customer. We have a data and equipment archive system that is perfect. The information of the customer's equipment is kept both digital and paper formats. Mold updating may include illustrations or Customization. After-sales assistance is provided by our expert team.

Suzhou VEDETTE, as a leading pipe bending machine cnc manufacturer in the market, puts the highest importance to technological innovation and investment in research and development, and continues to launch new products that compete to meet the increasingly diversified requirements of the market. We adhere to the quality of life, customer satisfaction as the primary objective and provide all the professional services covering pre-sales consulting, sales technical support, after-sales service, and ensuring that customers get the benefit of timely and professional technical assistance and solutions. Our products can be applied to a variety of industries. Suzhou VEDETTE which is a major manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.

We have always pipe bending machine cnc high-quality as the primary objective by ensuring that we control the source monitoring of production processes, continuous improvement and other measures to ensure the highest quality and consistency of the quality of our products. We will keep adhering to this principle in the near future, and will continue to improve our products and services in order to offer greater value to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd. was established in pipe bending machine cnc in the picturesque Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. With more than a decade's expertise in the development, research and manufacturing of tube processing equipment, as well as various types of customized production lines for automation It is a major National high-tech company engaged in the creation and production of technologically advanced, automated, and advanced equipment. As of December 2022, the company holds 31 utility model patents as well as 10 patents for inventions of equipment. Its equipment is highly regarded both in China and around the world, with many clients.