Many machines work in the factories and manufacturing plants to create products faster. Among these machines, the automatic pipe bending machine is a very important one. This one-of-a-kind machine was specially made so that Vedette copper pipe punching machine can bend pipes of any length, type and diameter through their natural radius in the simplest manner possible. This helps factories run faster and make more things in less time.

There are quite a few advantages that come with using an automatic pipe bending machine. Vedette single-shaft punching machine saves a lot of time first. The process of raisning and lowering a pipe essentially repeats the following technical steps, executed by computer-controlled bending machines, for every length of tubing used in automotive exhaust systems: Which means the factories can produce more number of pipes in less time interval. Also, it saves money when one considers that you will hire an operating machine because a similar machine can work for hours on end without getting tired. The machine on the other hand can carry on with working, unlike a person who needs breaks and rests which is very useful for businesses.

Automatic Pipe Bending Machine can also save a lot on labor costs. Since the bending of pipes can now be done by a machine, this has resulted in employing less number of workers to do it. This enables companies to spend less on workers manually fulfilling tasks which may be relatively repetitive. Additionally, Vedette Multi-spindle punching machine is very fast and thus helps the company to produce more products during a certain period of time. It means the company saves on labor and is just overall more productive he explained.

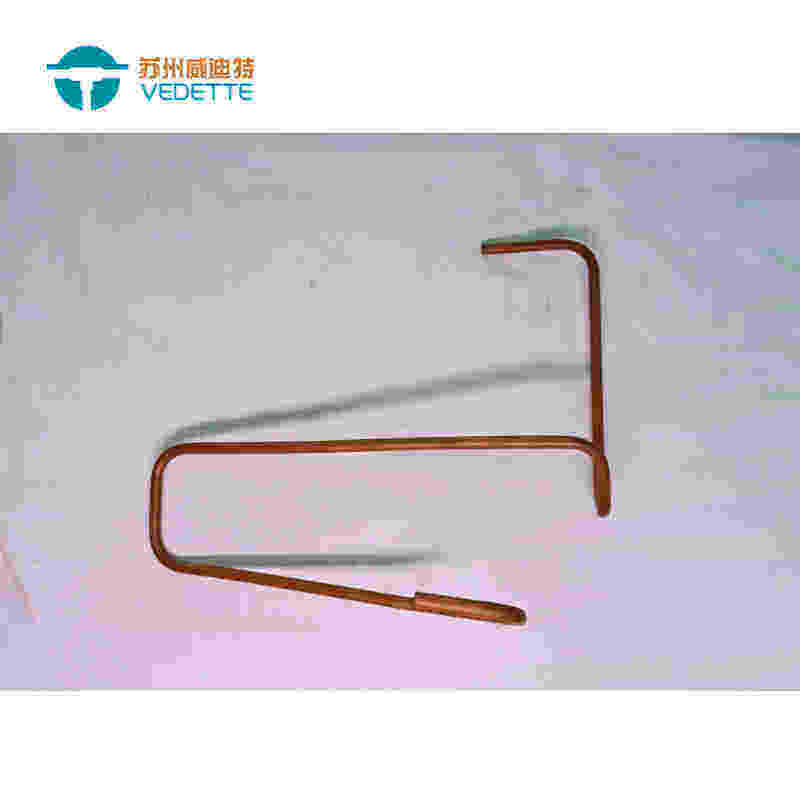

The power and accuracy of automatic pipe bending machine One of the most amazing features about these machines is in their powerful operation. These are very powerful machines that can create smooth bends in the pipes with tremendous accuracy. This accuracy is critical for a lot of businesses where their products must be the same each time. Accessibility to various sizes of different types of pipes is possible due to the superior strength that this machine offers and as a result, Punching and pulling machine become one very flexible tool for manufacturers with multiple manufacturing processes.

If you are also planning to buy an automatic pipe bending machine for your factory, then you must not miss this out. Multi-hole punching machine can be used to save time and money, to generate precision products in a consistent manner, as well as tackle differing materials types and pipe diameters. Is a useful tool that can make your factory better and smarter.

Suzhou Vedette Industrial Equipment Co., Ltd. was established in Automatic pipe bending machine in the picturesque Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. With more than a decade's expertise in the development, research and manufacturing of tube processing equipment, as well as various types of customized production lines for automation It is a major National high-tech company engaged in the creation and production of technologically advanced, automated, and advanced equipment. As of December 2022, the company holds 31 utility model patents as well as 10 patents for inventions of equipment. Its equipment is highly regarded both in China and around the world, with many clients.

We are the one-stop supplier for equipment to process pipes providing a range of equipment to meet your needs. We are focusing on the field of pipe processing automation equipment since more than 10 years and are able to offer more than 1,000 non-standard design schemes. Experienced sales projects will customize services following a thorough analysis of customer demands. Our equipment is produced and developed according to the Automatic pipe bending machine. The process of assembly and debugging can be seen online by customers at any time. They will conduct an exit inspection strictly in line with the process for delivering the exit once the equipment is accepted so that the equipment can be quickly integrated into the factory production tasks of the customer. We have an archive system for data and equipment system that is completely reliable. All equipment information of customers is preserved in paper files and electronic files. Mold updating can provide illustrations or Customization. After-sales services are provided by our professional team.

To ensure stability and quality in the Automatic pipe bending machine of our products We adhere to the premise of quality first and implement other measures such as control of the source as well as monitoring the process of production and continuous improvement. In the future we will continue to keep to the principle of quality first. We will continue to enhance the quality of our products and services to create greater value for customers.

Automatic pipe bending machine, as a top pipe processing equipment manufacturer in the field, places great importance to technological innovation and research and development investment and continues to introduce new products with market competitiveness in order to meet the changing needs of the market. We are committed to provide you with expert services, including pre-sales consultation and sales technical support and after-sales support. This will ensure that customers receive prompt and reliable solutions. Our products are highly applicable to a variety of industries. If you are a user who requires pipe processing equipment Suzhou VEDETTE is a reliable best choice.