Have you ever seen a metal tube or pipe bent into a specific shape? Special machines called hydraulic pipe and tube bending machines perform this bending. These machines are crucial because they actually bend metal pipes or tubes into different shapes and angles that are required for a range of applications. It would be much more difficult to create the shapes that engineers and builders need without these machines.

Hydraulic bending machines operate by applying pressure to bend a metal pipe or tube. They bend at thousands of pounds of pressure; kind of like if you were to squeeze a straw until it bent, just bigger! Grommets cover a lot of works, they just come in different sizes and shapes for different bending tasks. There are also machines that can bend very thick pipes or tubes, which makes for strong products. These machines are ideal for producing many items efficiently and quickly, making it very useful for manufacturers that must manufacture large quantities of products in a short period of time.

Hydraulic pipe and tube bending machine is very helpful, as it is make production easier and faster. Factories use these machines to bend pipes or tubes at a much faster pace. This guarantees that the entire process is efficient and, therefore, everything goes as they should without wasting time and materials. Businesses can produce more satisfying items for their customers without having to spend too much money or time by utilizing these machines.

These machines are used across a wide range of industries. For instance, automotive manufacturing relies on them, and this is just one example of how it is used to ensure high precision in car part production. In aerospace, these machines are used to manufacture parts of airplane components, which is critical to the safety and performance of the aircraft. Hydraulic bending machines: These are used in construction where there is a need to bend steel beams in order to build strong frames for foundations, structures, buildings etc. This also applies to other sectors such as marine and rail where robust and accurate shaped metal components are required.

Metal can be bent through techniques so that the hydraulic pipe & tube bending machine can help. They are able to bend components such as pipes or tubes to countless shapes, angles, and dimensions to ensure that the resulting end product is perfect. It is of utmost importance for quality that some of these machines have state-of-the-art computer-driven systems that ensure each and every bend is just perfect. Other machines allow the operator to control the bending process directly, offering far more flexibility in shaping the metal.

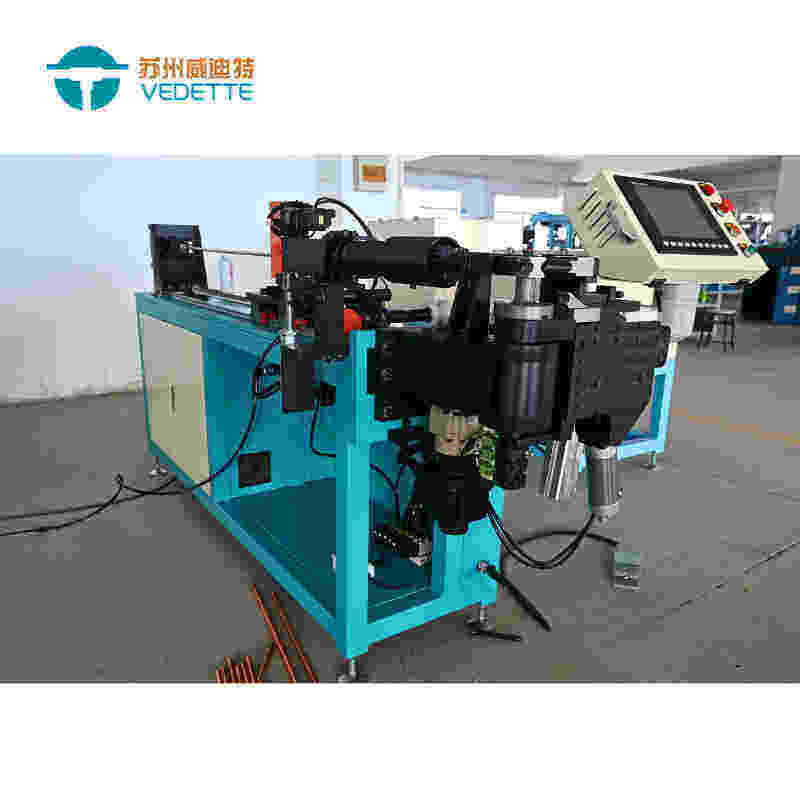

Our hydraulic pipe and tube bending machines can serve a multitude of production requirements at Vedette. We engineer our machines with precision, so each time you send to print you know you will get great results. We have manual machines, requiring an operator, and computer-controlled machines to help automate the process for Speed of Production. The diversity available makes it possible for all businesses to discover every machine that can work with their particular requirements, regardless of the size of the operation.

The machine is used in many industries, including automotive, aerospace, construction, marine, and rail. They are also popular among small businesses that require a custom part or product made of metal. Our machines enable small businesses to produce quality items seamlessly and out compete larger organizations.

Our company is manufacturing pipe processing automation equipment for more than 10 year and we have over 1,000 design schemes that are not standard. pipe and tube bending machines hydraulic sales teams can customize services based on a thorough understanding of customer demands. The process of planning the project is followed to manufacture and test our equipment. Customers can follow the equipment's construction and debugging progress on the internet anytime. They will conduct an exit inspection following the strict process for delivering the exit after the equipment has been accepted to ensure the equipment can be quickly integrated into the factory production processes of the customer. We have an archive system for data and equipment system that is flawless. The customer's data equipment is saved both in the form of paper and electronic files. The mold updating service could be used to provide drawings or Customization. After-sales assistance is provided by our expert team.

Suzhou VEDETTE is pipe and tube bending machines hydraulic leading producer of pipe processing equipment in the field. It focuses heavily on technological innovation, research and development, and launches new products that compete to meet the ever-changing demands of the marketplace. We are committed to quality of life and customer experience as our main goal we provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance, to ensure that customers get the benefit of timely and professional technical assistance and solutions. Our products have a wide range of applicability to meet the requirements of various industries that require pipe processing. For the users who need pipe processing equipment Suzhou VEDETTE is definitely an excellent choice.

To ensure stability and quality in product quality We adhere to the principle of quality first, and take other measures like source control, pipe and tube bending machines hydraulic the production process and constant improvement. In the future, we will continue to stick to the principles of quality first, constantly improve the level of products and services to bring more value to our customers.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in southwest Suzhou in close proximity to Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a highly-tech national company with more than a decade's experience in research, development, manufacturing, and customizing automation production lines. At the time of its December 2022 launch, it was the holder of 31 utility models and 10 patents on inventions of equipment. The equipment it produces is highly pipe and tube bending machines hydraulic both in China and around the world, with numerous customers.