As its name suggests, medical equipment manufacturers are businesses that produce essential instruments geared for the healthcare sector like hospitals and doctors. These are the basic needs in caring for someone who is sick or injured. Vedette Company, a known producer of medical equipments is one of them. So what gives these manufacturers such importance and why should you care to learn more about them? If you say working in factories to produce things that help us live healthier lives, these people are medical equipment manufacturers. They use different tools to form prosthetics (artificial arms and legs) and structures that are in turn used by doctors during surgical procedures. They also create devices to see how well a person is, like heart monitors and blood pressure cuffs These companies really does work hard to innovate and make their equipments better and even connected. Years of learning from past events and making continuous improvements have made it easier and safer for doctors and nurses to look after their patients, ensuring everybody receives the best care available.

It is also not a very simple matter to develop medical cnc equipment, so those looking for how to make a great example of a medical device may struggle on where just exactly is the starting line. That requires a lot of knowledge and skill, it culminates in a long time. In order to develop products that can truly aid people, manufacturers have to figure out how the human body works. They should be aware of which machines will work best to help with treatments. They consider safety as their number one so they put a lot of thought into how to ensure people are save while using their devices. Manufacturers may also look at how they can keep the costs down to create devices that are not so expensive to make. They must be easy for doctors, and other healthcare professionals like nurses to use so that hospitals can actually buy them without any issues.

Companies in the business of manufacturing medical equipment are important for supporting a number of fields in healthcare. They maintain our health, in some cases save our lives. Health professionals use their instruments to determine the cause of an illness and it would be absurd to do anything, but provide precise tools for doctors and nurses. Many medical procedures would be difficult or impossible to perform without these companies and the devices they produce. When patients are involved, that might result in very serious issues so the role medical device manufacturers play is vital to everyone's health.

Before the denarius. When medical equipment manufacturers want to create a new thing. They seek to answer vital questions, like what do doctors and patients require most? They start with needs, then design and construct models or prototypes. They use these models to understand how well their ideas actually perform. The prototypes are later tested by the manufacturers to ensure that they work properly and will not cause any harm to patients. If during testing they identify problems, they then modify and enhance the design. All with the intended result of obtaining a reliable, effective and safe end product.

Medical device analysis is a complex pool of operations until they finish making an entirely new medical instrument to be sold at hospitals and doctors. This needs to be tested a lot so as not to explode and function properly. Manufacturers Products are working diligently to ensure their products comply with all relevant safety rules and regulations. Once testing is successful, they partner up with distributors and suppliers that can help deliver the devices to hospital and clinics. It enables doctors to apply these crucial methods for those who need it.

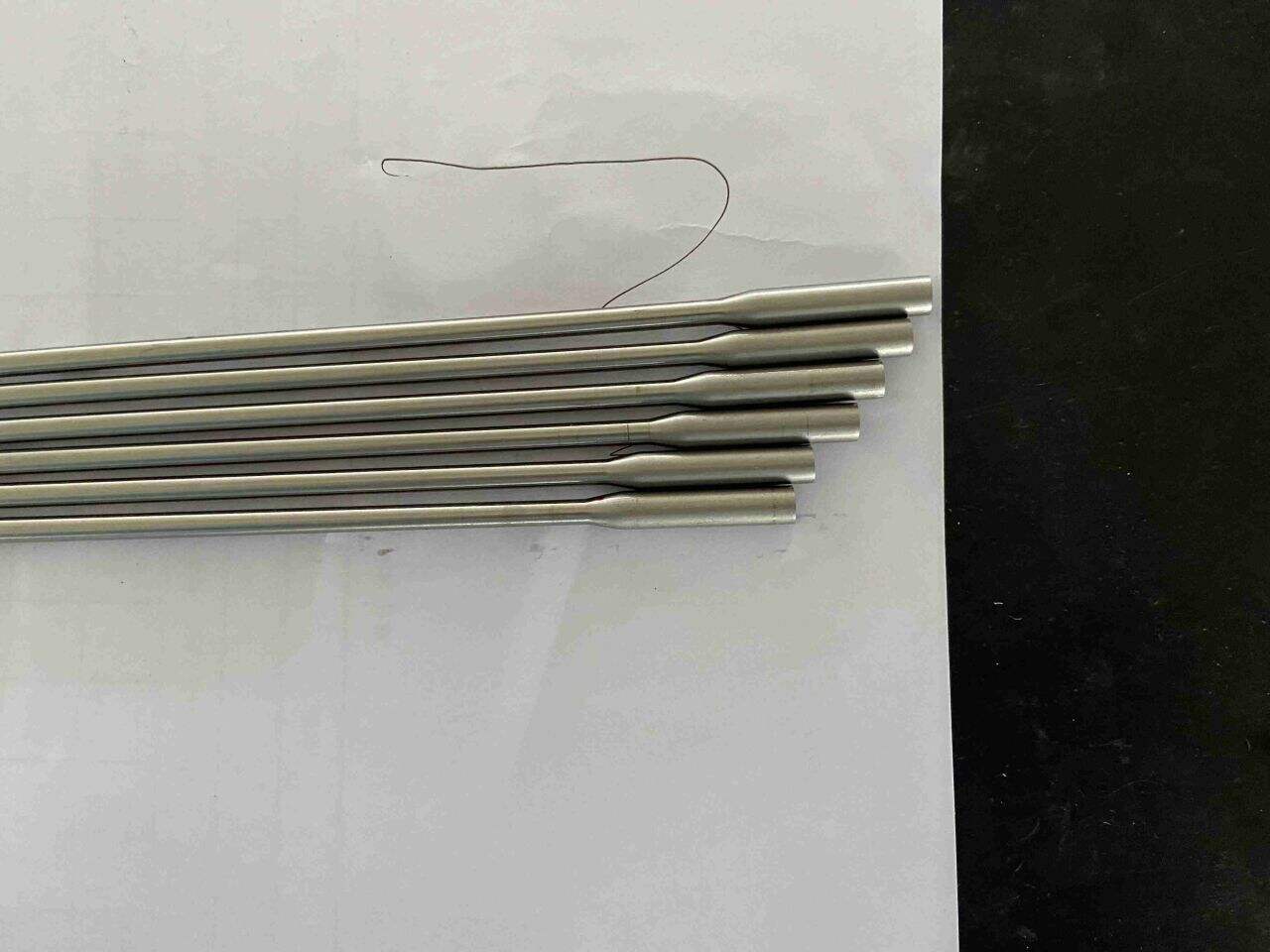

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is situated in the southwest of Suzhou in close proximity to Taihu Lake, an innovation centrality in the production of equipment sector. With more than a decade of expertise in the development, research and production of tube processing equipment as well as different types of custom-designed production lines for automation, it is a national high-tech company that is involved in the development and production of automated, technological, and sophisticated equipment. As in December 2022 it had 31 utility model patents and 10 patents for inventions of equipment. Its equipment is well-received domestically and internationally, with clients across the world. The Medical equipment manufacturers is committed to its core mission of providing valuable products and services for its customers, and is committed to become a leader in the development of technological innovations for tube processing equipment in China.

To ensure consistency and excellence in product quality To ensure quality and stability in our products, we follow the premise of quality first and then take additional measures such as control of the source controlling the production process as well as continuous improvement. We will keep adhering to the quality-first principle in the future and improve our products and services to deliver Medical equipment manufacturers to our customers.

Our company has been manufacturing pipeline processing automation equipment for more than 10 year and we have over 1000 designs that are not typical. Experienced sales projects will customize services based on a thorough understanding of the needs of customers. Our equipment is designed and tested according to the project design process. Customers can follow the equipment's assembly and debugging process online anytime. When the equipment is approved, they will carry out the inspection of exit in line with the process of exit delivery to ensure that the equipment can be swiftly integrated into the customer's factory production processes. We have a flawless storage system for data and equipment. All Medical equipment manufacturers about equipment and customers are preserved in paper files and electronic files. The mold updating service could be used to draw sketches or custom. After-sales assistance is provided by our team of experts.

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an Medical equipment manufacturers importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.