Ever wonder how they make pipes? Pipes play a very crucial role as they are responsible for carrying water, gas and several other things from one place to the other. They have broad application in every home, building and industry of the world. In days gone by, pipes were hand bent, as it was a slow and error prone process. This was both slow and complicated, there was also a potential that it might not work properly. However, recent technology has allowed the bending of pipes to become a lot quicker, faster and more accurate to do.

CNC tube bending is definitely a good deal more advantageous than manually shaping pipes with your hands. It was, one, faster and better performing than what we did on our own. The computer does the bending so the measurements are precise and the angles consistent. This ensures that Vedette cnc pipe bender for sale fit the lines up accurately which can save time and eliminate errors. There is no need to correct the pipes later on, which can be quite a headache when all goes well.

The second is that we can save funds on Vedette cnc pipe bender for sale. This lessens human mistakes and the material wastage. This should be a big factor as wasting materials does mean you are wasting cash. Bending is also done faster and more pipes can be bended in one pass. They can then pass the savings on to their customers, offering better prices while spending less on materials and labor.

An electrical CNC tube bending machine is a machine that uses electric motors to bend the tube. The tube is then pulled through a shaped die by the machine, while its motors control the bending of that shape. This is the most hygienic and systematic method to bend pipes. The machine can also alter shape from one bend to the next at the push of a button, with little additional attention required by operators.

Hydraulic CNC tube bending machines, on the other hand, utilize strong pressure in order to bend the tube. Instead of pulling the tube, it is pushed from outside of bend to inside of the bend using Vedette cnc roll bender. Good for thick types of pipes or even tubes and must be extra strong. Hydraulic bending machines are a lot of power so can fold hard materials and more parts than other machines can do.

For CNC tube bending results, some practices to get the best outcomes from the process are really vital. The very first and foremost, see that the tube you are using is of good quality and suitable for bending. Get a tube, make Vedette cnc roll bender the same thickness through all of it so that way it can bend evenly. Uneven thickness will make the bends appear bad and can result in issues further down the line.

The second advice is to use a support tool during the bending. It could be a jig or template that gets clamped around the tube to keep it from moving as it is bent. This prevents the Vedette chamfer cnc from being benched wrongly, making it more precise. Workers guarantee that each bend is actually correct as it needs to be by making use of a support tool, leading to far better results.

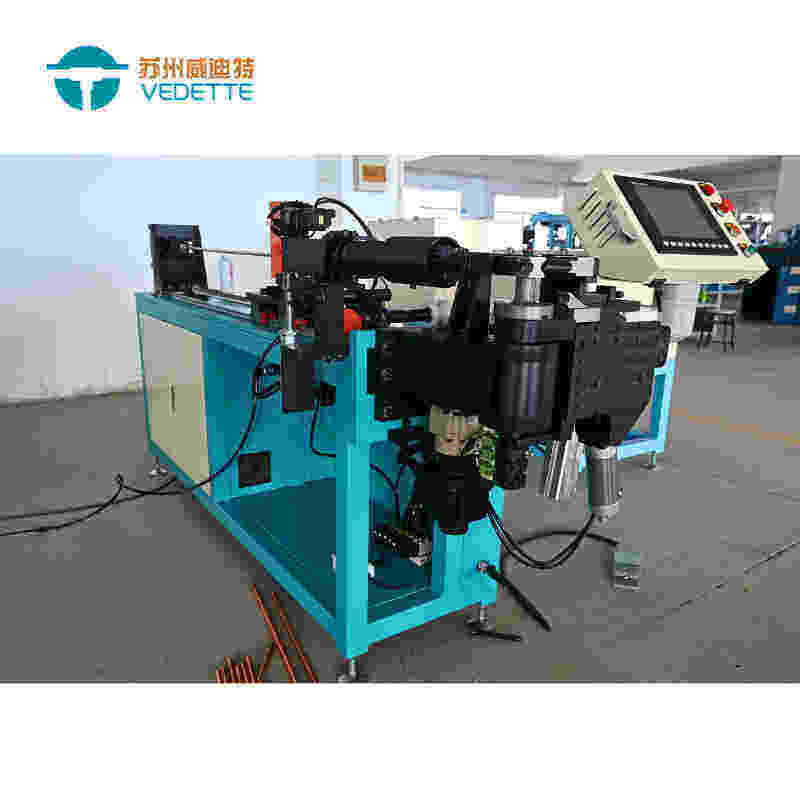

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the Cnc pipe bending machine price. It puts a lot of emphasis on technological innovation, research as well as development, and has launched new products that are competitive in keeping up with the changing needs of the market. We place quality of life, as well as the customer experience as the core of our business, and offer the full spectrum of professional services that include pre-sales consultation and technical support for sales, after-sales support, to make sure that customers get the benefit of professional and timely technical support and solutions. Our products have a wide selection of applications to meet the needs of different industries in pipe processing. Suzhou VEDETTE, a leading manufacturer of equipment for pipe processing is the best option for users.

We are the one-stop supplier for pipe processing equipment providing a range of equipment to meet your needs. We have been working on the area of automation equipment for pipe processing since more than 10 years and are able to offer more than 1,000 design concepts that are not standard. Expertly-trained sales teams can customize solutions based on an in-depth understanding of customer needs. Our equipment is produced and disassembled according to the project plan. Customers are able to monitor the equipment's assembly and debugging process online anytime. They will conduct an exit inspection following the strict exit delivery procedure once the equipment is accepted so that the equipment can be Cnc pipe bending machine price in the factory manufacturing tasks of the client. We have an equipment and data archive system that is perfect. The information of the customer's equipment is stored both in documents and in paper. The mold updating service can be used to create drawings or Customization. We have a highly skilled after-sales team that provides after-sales cleaning and maintenance.

Cnc pipe bending machine price will always keep quality of our products as the mainstay by ensuring that we control the source manufacturing process monitoring, source control constant improvement, among other things in order to guarantee the high-quality and durability of the product. We will continue to adhere this principle in the future and continue to improve our products and services in order to provide greater value to customers.

Suzhou Vedette Industrial Equipment Co., Ltd., formed in 2011, is situated in southwest Suzhou in close proximity to Taihu Lake, an innovation hub in the equipment manufacturing sector. It is a highly-tech national company with more than a decade's experience in research, development, manufacturing, and customizing automation production lines. At the time of its December 2022 launch, it was the holder of 31 utility models and 10 patents on inventions of equipment. The equipment it produces is highly Cnc pipe bending machine price both in China and around the world, with numerous customers.