One of the very interesting and unique technologies used across different parts of the world is CNC cutting. It has really streamlined things for many corporations and the people who work there. Vedette is one of the leading CNC cutting technology companies, which ensures that it redoubles its efforts to help customers achieve great results.

Precision — CNC cutting systems allow for precise, intricate cuts every time. Translation: The cut designs that people put into these machines are programmed to make only the computers. Due to this accurate cutting, it provides the exact result, and less errors are occurred as compared to when a person cuts items with hands. This becomes even more useful when you are creating intricate or entails cuts as Vedette Cutting machine can it can cut those shapes and details in no time.

CNC cutting is also time-saving which is one of the amazing benefits it has to offers. When workers used traditional cutting methods before, they would first measure and mark the materials before doing the cutting. And it was slow, and often times painful to work through. Well, with CNC cutting machines they can perform these tasks a lot more quickly and accurately. Therefore, they can handle and complete more projects faster, which is highly beneficial for its own growth and success.

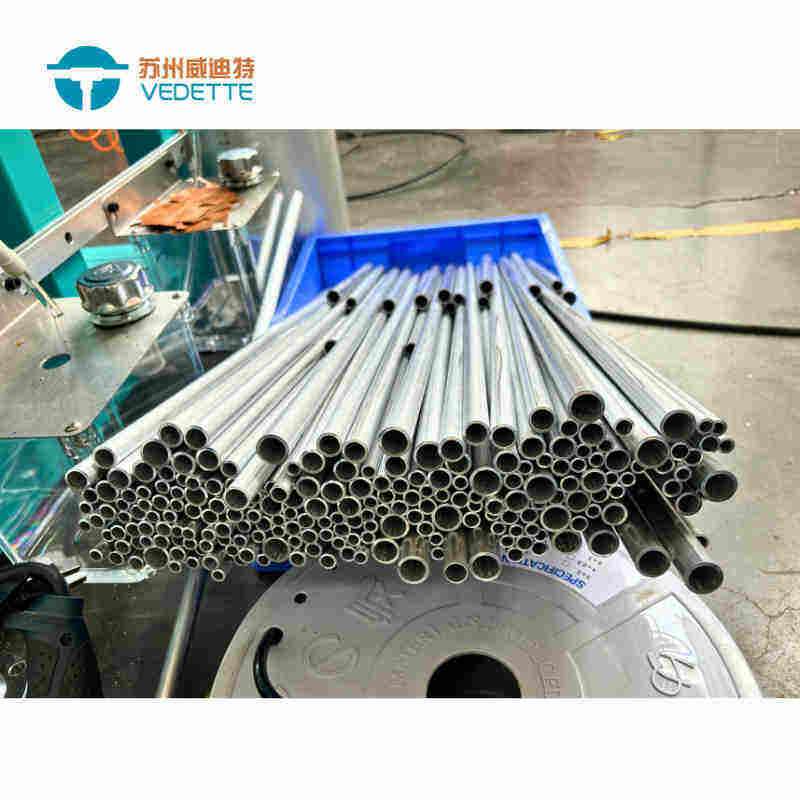

CNC laser cutting is a technique that employs the use of high-powered laser beams to cut through materials, and it's a method of deliberating cutting for industrial manufacturers. Vedette straight pipe cutting machine is particularly suitable for metals, plastics or wood. Laser cutting is fast, accurate and yields a good looking clean cut. That said, the practical advantages me immediately make most businesses want to do laser cutting for their projects.

The future of the making is going to influenced in no small amount by digital technology, one avenue of this will be CNC cutting. The more companies that engage in digital technology use, they can create faster flow, cheaper and higher-quality product. This trend is well understood by Vedette, the company offers its clients high-quality CNC cutting services to enhance their business and stand up against any competition in the market.

Businesses need to be unique in the market and CNC cutting surely helps them to do that. One of Reda's proprietary technologies is called Manufacturing as a Service and a growing number of manufacturers are taking advantage of this process to get high-quality products fast. This gives businesses a competitive edge to gain more customers and scale their businesses.

Special cutting tools perform the cuts, on a lathe — The Vedette Four-tube chipless cutting machine uses cutting tools that are different from those in traditional machines The tools will differ depending on what is being cut and how it is intended to be cut. Laser cutting works by heating up a powerful beam of energy, and waterjet cutting relies on the strong to push through with.

Suzhou VEDETTE is a leading Cnc cutting of pipe processing equipment in the field. It places great emphasis on technological innovation, research as well as development, and has launched new products that are competitive to meet the ever-changing demands of the market. We're committed to provide you with expert solutions that include pre-sales consulting as well as sales technical assistance and after-sales support. This ensures that our customers get prompt and efficient solutions. Our products are broadly applicable to different industries. Suzhou VEDETTE which is a major manufacturer of equipment for pipe processing is the best choice for users.

We have always Cnc cutting high-quality as the primary objective by ensuring that we control the source monitoring of production processes, continuous improvement and other measures to ensure the highest quality and consistency of the quality of our products. We will keep adhering to this principle in the near future, and will continue to improve our products and services in order to offer greater value to our customers.

We are your single-stop source for equipment to process pipes, offering a range of machines to fulfill your needs. We are Cnc cutting on the field of automation for pipe processing equipment for over 10 years and have nearly 1,000 design concepts that are not standard. Sales professionals with experience can tailor services after detailed understanding of customer demands. Our equipment is designed and debugged according to the project schedule. Customers can watch the equipment assembly and debugging progress online anytime. When the equipment is approved and inspected, they'll carry out exit Inspection in strict accordance to the exit delivery procedure to ensure that the equipment will be promptly incorporated into the customer's factory production tasks; We have a perfect storage system for data and equipment. The data of the equipment used by customers is stored in paper files as well as electronic files. Mold updating will provide sketches or custom. We have a highly skilled service department after sales and can provide after-sales cleaning, maintenance and cleaning.

Cnc cutting was founded in 2011 and is located close to the gorgeous Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the production of equipment. With more than a decade of expertise in the development, research and production of tube processing equipment and various kinds of custom automation production lines that are a national high-tech company that is involved in the development and production of technologically automated and intelligent equipment. As in December 2022 it has 31 utility model patents, and 10 equipment invention patents. The equipment is well-received both domestically and internationally, with clients across the world. The company abides by its corporate goal of offering valuable products and services for its customers and is dedicated to being a leader in the field of technological advancement for tube processing equipment in China.