Finally, you will have to prepare the matter. No matter if its metal, plastic or wood you use be sure it is securely fastened to the machine. It is a process that's known as "fixturing." “Two — A technician has to do this and you have to follow the step-by-step instructions meticulously to ensure that the material stays in place during the process as per the directive of Apply Care. Any looseness in the material could cause it to slip while cutting which would be catastrophic for your design

In conclusion, the only thing left is to start out the device. Islam called it "running the machine. “ You will have to keep an eye on the machine that it is working fine and there is no issue in shaping of the material. This Vedette pipe bending equipment might be a little bit difficult in the beginning especially if you are not used to working with CNC machines. But once you are experienced enough, you can get hang of it and using CNC machines feel like child's play And this is a highly rewarding skill.

Clean Well done on keeping your machine clean First and foremost. This means that it should be cleaned on a regular basis, oiled as well for the moving parts lubing and check to see if its functions appropriately. An immaculate machine works optimally which means faster manufacture of more products. However, if the equipment is dirty or not well maintained, it might not result in an efficient work and may have you working a bit slow

Then, compare everything with your own computer and the best settings that can run on it. That said, you will need to test out the speed and tools for your specific material. Mise en Place requires a well-tuned machine to both run successfully as well as turn out the product accordingly. By every means these settings take a lot of time, but if you do it, the consequences will amaze you — your work will improve greatly both in quality and speed.

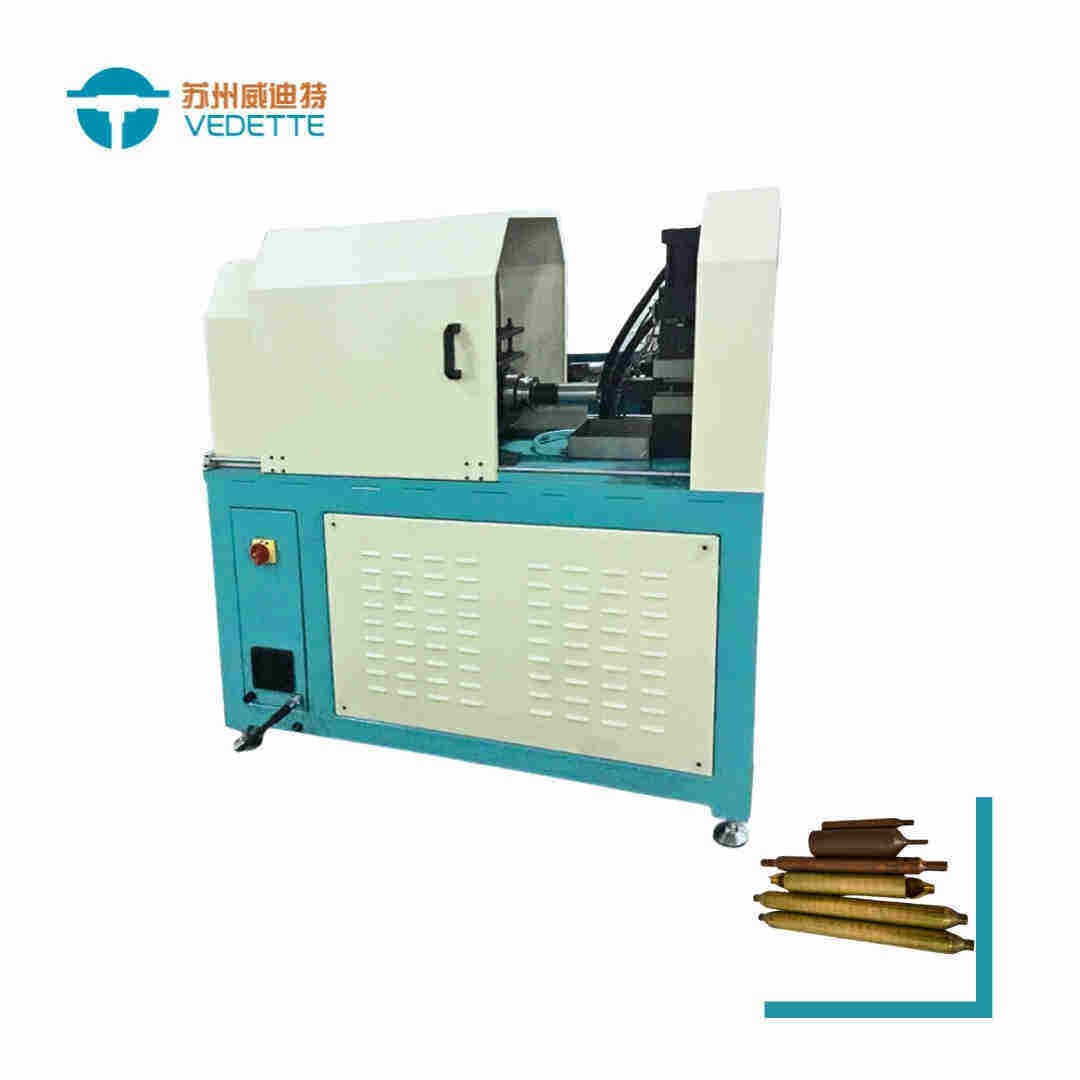

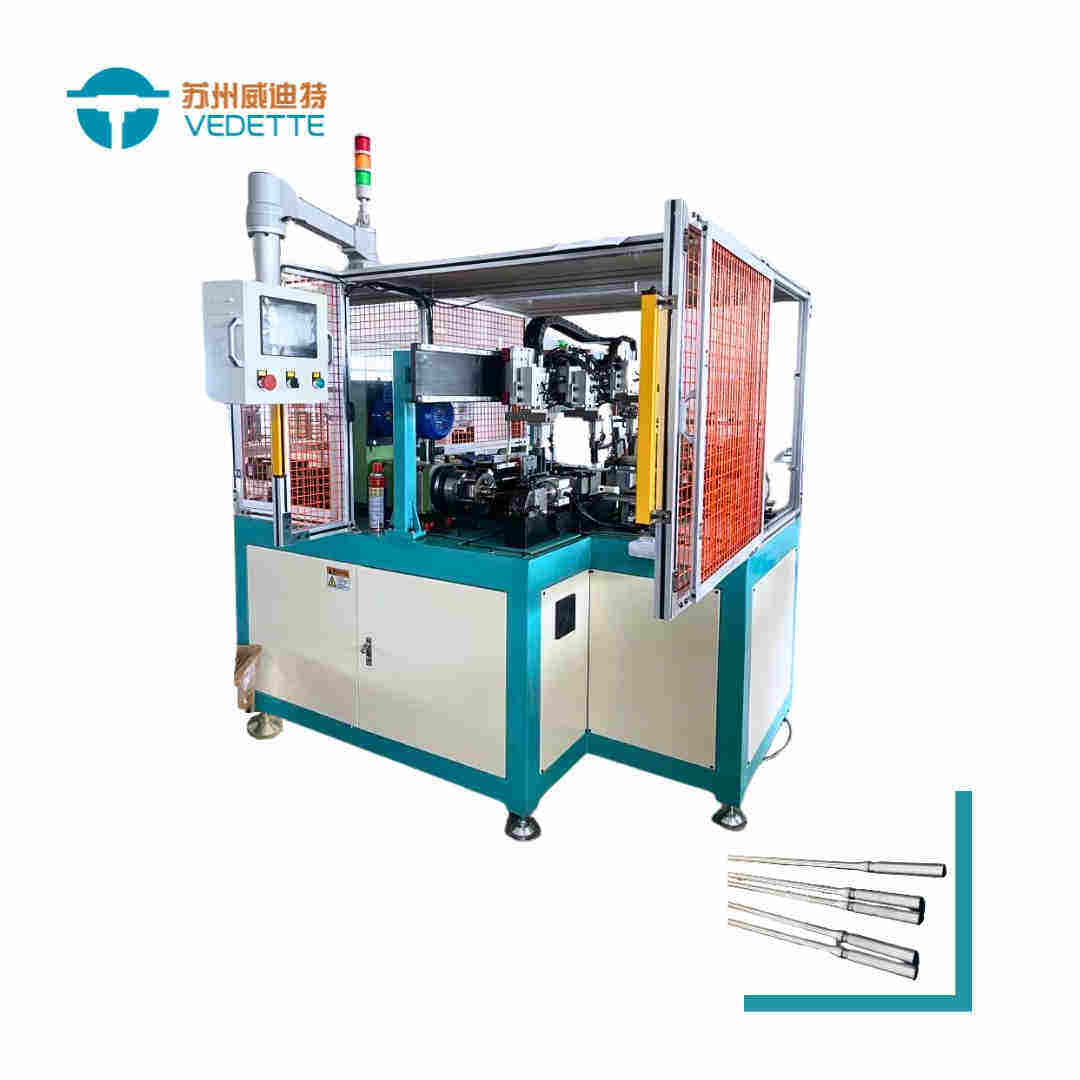

Rapidity-CNC machines are very rapid as comparison to the manual working process. These cutters are compatible with a variety of materials, including metal, plastic, wood and even ceramics. This allows you to use Vedette CNC bending equipment for a wide range of projects, from creating medical devices, custom motorcycles, or works of art. CNC machines are used as valuable tools in a variety of industries thanks to their ability to work with different materials.

Lastly, CNC machines can be made to accommodate changeable designs and produce large quantities of products. It is easy to alter the program in order to vary your design, and after the program has been set up much more can be generated fast and also efficiently. This feature makes the CNC machines have intended customers in companies which require high patch production together with short lead time and stringent quality assurance.

Safety gear should be worn at ALL times when operating the Vedette tube bending equipment. This includes proper safety glasses to shield your eyes, ear protection to keep your ears guarded from loud sounds, gloves to protect your hands, and a mask of some kind if needed. When machine works, its pieces will be flying around; water jet can make quite loud noises and its dust or sandblasting chemicals can also be harmful if inhaled / to your eyes / ears etc. You have to wear such-n-such safety gear (glasses, helmets with built-in ear-protectors) when operating it.

Suzhou Vedette Industrial Equipment Co., Ltd. was established in Cnc equipment in the picturesque Taihu Lake in the southwest of Suzhou and is a major center of technological innovation in the production of equipment. With more than a decade's expertise in the development, research and manufacturing of tube processing equipment, as well as various types of customized production lines for automation It is a major National high-tech company engaged in the creation and production of technologically advanced, automated, and advanced equipment. As of December 2022, the company holds 31 utility model patents as well as 10 patents for inventions of equipment. Its equipment is highly regarded both in China and around the world, with many clients.

Suzhou VEDETTE is a leading manufacturer of pipe processing equipment in the Cnc equipment. It puts a lot of emphasis on technological innovation, research as well as development, and has launched new products that are competitive in keeping up with the changing needs of the market. We place quality of life, as well as the customer experience as the core of our business, and offer the full spectrum of professional services that include pre-sales consultation and technical support for sales, after-sales support, to make sure that customers get the benefit of professional and timely technical support and solutions. Our products have a wide selection of applications to meet the needs of different industries in pipe processing. Suzhou VEDETTE, a leading manufacturer of equipment for pipe processing is the best option for users.

We Cnc equipment adhere to the quality as the core by ensuring that we control the source, production process monitoring and continuous improvement as well as other methods, to ensure the excellence and reliability of the product. We will keep adhering to the quality-first principle into the future and improve our products and services in order to offer greater value to our customers.

Our company is manufacturing pipe processing automation equipment for more than 10 year and we have over 1,000 design schemes that are not standard. Cnc equipment sales teams can customize services based on a thorough understanding of customer demands. The process of planning the project is followed to manufacture and test our equipment. Customers can follow the equipment's construction and debugging progress on the internet anytime. They will conduct an exit inspection following the strict process for delivering the exit after the equipment has been accepted to ensure the equipment can be quickly integrated into the factory production processes of the customer. We have an archive system for data and equipment system that is flawless. The customer's data equipment is saved both in the form of paper and electronic files. The mold updating service could be used to provide drawings or Customization. After-sales assistance is provided by our expert team.