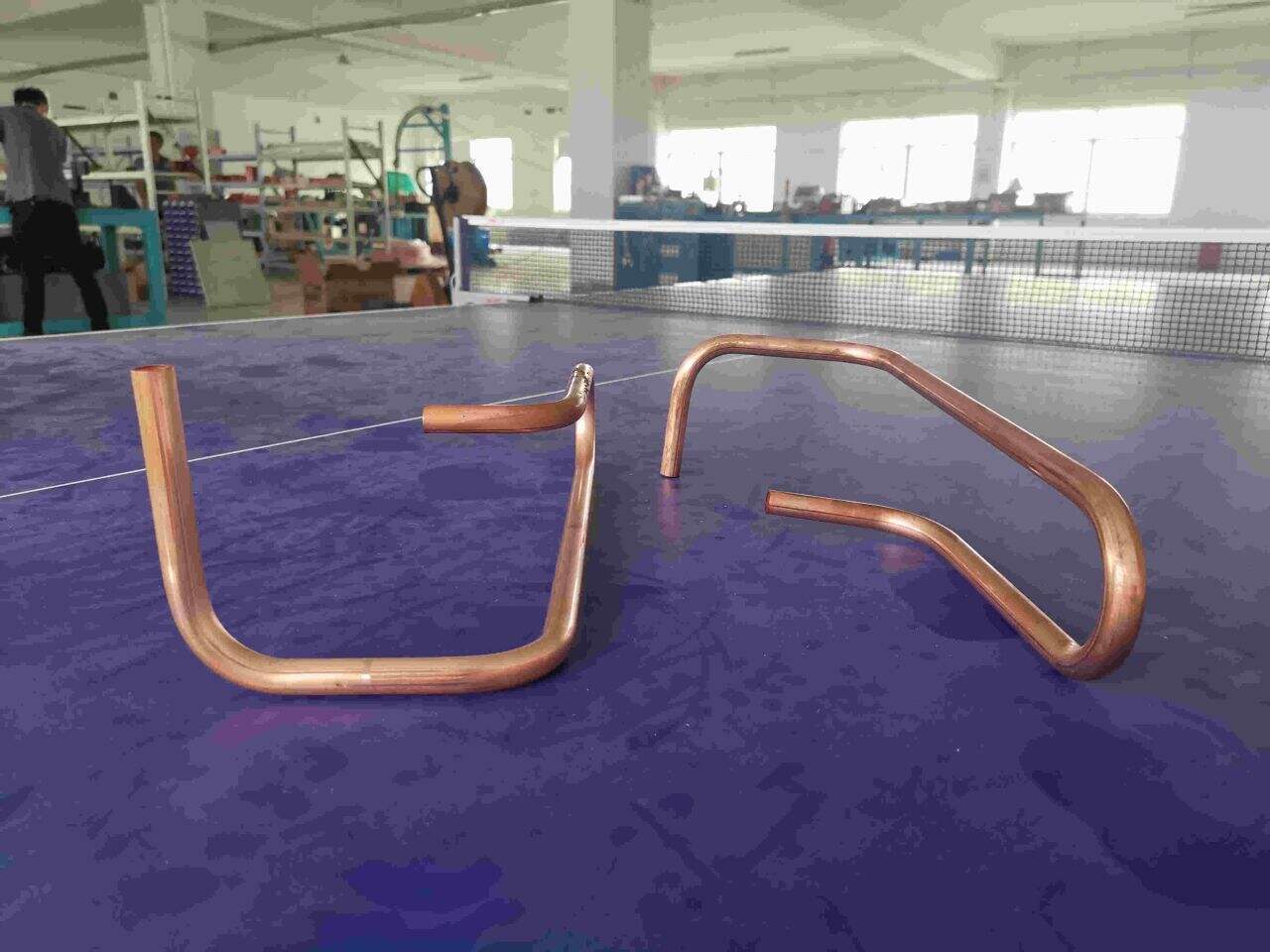

Tutti sanno come si piegano le tubazioni e assumono forme? Beh, avviene in modo affascinante attraverso macchine per il piegamento delle tube CNC. CNC significa controllo numerico computerizzato. Qui, il computer controlla e coordina il modo in cui queste tubazioni devono essere piegate. Infatti, il computer è intelligente e si assicura che le tubazioni siano piegate e realizzate nel modo corretto. Per cominciare, Vedette macchina per il taglio di tubi retti utilizza uno strumento speciale noto come mandrino. Il mandrino è importante perché supporta l'interno della tubazione quando questa viene piegata. Altrimenti, una tubatura potrebbe danneggiarsi e venire piegata nella forma sbagliata in assenza di un mandrino. In secondo luogo, le macchine ruotano la tubazione contemporaneamente al suo piegamento per ottenere la forma desiderata per eseguire un compito specifico. Esattamente, il computer istruisce la macchina su cosa fare e come farlo. Questo è eccellente

Incredibilmente, le macchine per la curvatura delle tubazioni CNC possono piegare tubi in molte forme geometriche e vari angoli. Poiché diversi lavori richiedono tubi in grado di posizionarsi correttamente, ciò è diventato imperativo. I tubi vengono piegati anche per altri motivi, come ad esempio per girare intorno agli angoli o alle aree strette. E possono produrre forme complesse quasi impossibili da realizzare altrimenti. Queste macchine sono flessibili e incoraggiano nuovi progetti di tubi.

Troverai molte applicazioni per tubi personalizzati in automobili, aerei e persino nella sanitazione degli edifici. Tubi speciali possono aiutare i motori nell'industria automobilistica a funzionare meglio e più efficientemente. Desiderati per il loro rapporto resistenza-peso, possono produrre componenti sia interni che esterni nell'industria aerospaziale. Questi tubi possono anche essere utilizzati negli edifici e nelle strutture, per fornire servizi di riscaldamento o raffrescamento per l'interno vicino di queste strutture.

Velocità: Possono lavorare velocemente ed efficacemente, il che significa che i tubi vengono prodotti molto più rapidamente. Questa Vedette Macchina da taglio così le aziende possono risparmiare molto tempo e aumentare la produzione.

Personalizzazione: possono produrre tubi in una serie di forme per adattarsi a diversi requisiti. Questa capacità di personalizzazione è estremamente utile in molti settori.

Automazione: Essere in grado di lavorare autonomamente rende più facile produrre più pipeline Vedette Prodotti senza la necessità di lavoro umano per ogni unità.

Suzhou Vedette Industrial Equipment Co., Ltd. è stata fondata nel 2011 ed è situata presso il suggestivo Lago Taihu, nella zona sud-occidentale di Suzhou, ed è un importante centro di innovazione tecnologica nella produzione di impianti. Si tratta di un’azienda nazionale di prim’ordine con oltre 10 anni di esperienza nella ricerca, nello sviluppo, nella produzione e nella modifica di linee di produzione automatizzate. Per quanto riguarda le attrezzature CNC per la piegatura di tubi, l’azienda detiene 31 modelli di utilità e 10 brevetti per invenzioni relative a tali attrezzature. I suoi impianti sono molto apprezzati sia in Cina che all’estero, con numerosi clienti.

Abbiamo sempre considerato l'equipaggiamento per la piegatura di tubi CNC di alta qualità come obiettivo primario, garantendo il controllo alla fonte e il monitoraggio dei processi produttivi, nonché misure di miglioramento continuo, al fine di assicurare la massima qualità e coerenza dei nostri prodotti. Continueremo a rispettare questo principio nel prossimo futuro e miglioreremo costantemente i nostri prodotti e servizi per offrire un valore ancora maggiore ai nostri clienti.

Siamo il vostro fornitore di attrezzature CNC per la piegatura di tubi, offrendo una vasta gamma di macchinari per soddisfare le vostre esigenze. Operiamo nel settore delle attrezzature automatizzate per la lavorazione di tubi da oltre 10 anni e siamo in grado di fornire più di 1000 configurazioni su misura. Dopo un’attenta analisi delle esigenze del cliente, il nostro esperto staff commerciale fornisce servizi personalizzati. Il processo di pianificazione dei progetti è seguito da produzione e messa a punto delle nostre attrezzature. Il cliente può seguire in tempo reale, online, l’intero processo di assemblaggio e messa a punto. Una volta accettata l’attrezzatura da parte del cliente, effettuiamo ispezioni finali in piena conformità alla procedura di consegna finale, al fine di garantire un’integrazione rapida dell’attrezzatura nei processi produttivi della fabbrica del cliente. Deteniamo un record impeccabile riguardo alle attrezzature e ai dati. Le informazioni relative alle attrezzature del cliente sono conservate sia in formato digitale che cartaceo. L’aggiornamento degli stampi rappresenta un metodo per fornire disegni o personalizzazioni. L’assistenza post-vendita è garantita dal nostro team di esperti.

Suzhou VEDETTE è un produttore leader di attrezzature CNC per la piegatura di tubi nel settore delle macchine per la lavorazione di tubi. L’azienda pone grande enfasi sull’innovazione tecnologica, sulla ricerca e sullo sviluppo, e ha lanciato nuovi prodotti competitivi per soddisfare le esigenze del mercato in continua evoluzione. Ci impegniamo a fornirvi soluzioni specialistiche che includono consulenza pre-vendita, assistenza tecnica in fase di vendita e supporto post-vendita. Ciò garantisce ai nostri clienti soluzioni tempestive ed efficienti. I nostri prodotti trovano applicazione in diversi settori industriali. Suzhou VEDETTE, importante produttore di attrezzature per la lavorazione di tubi, rappresenta la scelta migliore per gli utenti.