Ever wonder how a pipe factory can produce so many pipes within such short time frame? The secret is pretty easy: they have machines intended for pipe manipulation! Multi-spindle punching machine perform the following tasks better than any human and they speed up everything related to laying pipes in a business establishment

Efficiency; the ability to perform quickly and accurately, is key in today's business. If you want to make many pipes and a better quality of those pipes and if you want to produce that on time, properly managed then really you need very high-speed pipe machines. There are machines in different sizes and shapes ensuring that it is easy to find a fit of your factory. Some are small machines that work fine for a tiny factory, and some are big machines designed for huge companies that need to pump out tons of pipes.

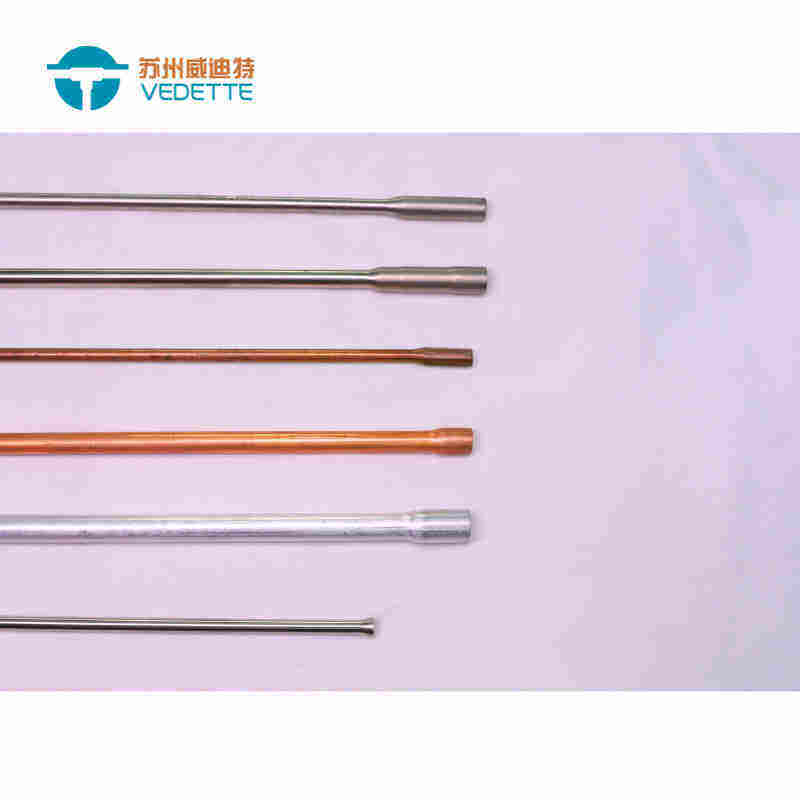

A great model of the rapid straight pipe cutting machine would be the Vedette pipe saw. The cutting machine is designed to provide fast and precise pipe cutting. As a result, your factory is able to produce more pipes in less time. And because it functions quickly and with precision, your team will have more time to inspect the pipes before moving them on to the next stage in the process. This additional time makes fewer blunders, and eventually better-pipes

One of your requirements for small pipe machines that do not occupy more space if you have a small place or limited factors. The good news is there are many options you can use that will work great and don't take up a lot of room. For a small factory, choosing the correct machine that can help boost your production capabilities can be especially impact.

The best example of such a copper pipe punching machine is the Vedette compact pipe bender. It is perfect for pipe bending in small space with quick and easy operation. It is ideal for small businesses looking to maximize their production space. And most importantly, much like all the best bits of basic technology these days -- young workers can use it without fear or incident.

Fast production can easily lead to the need for a new threading machine as well, and one great option for businesses seeking to boost output is the Vedette high speed pipe threading machine. With this machine, pipes can be threaded in nothing flat so that your workers can have more pipes ready to go out the door sooner. Because it can be quite quick, it means that you will be able to handle more orders, without decreasing the quality of pipes you are manufacturing. This can be an very good way to help your business grow!

Vedette custom pipe bender The Vedette is a classic example of a tailor-made one-off machine. If you are looking for a machine that can do pipe bending at awkward angles or the one which can milder to heavier materials, Vedette could provide you with the solution that best suits your factory needs. Building custom machines makes sure you get what you need to keep churning your product.

Our Pipe processing machine has been manufacturing pipes processing automation equipment for more than 10 year and we have over 1,000 design plans that aren't conventional. After a thorough understanding of the needs of our customers and requirements, our experienced sales team will tailor services. Our equipment is produced and debugged according to the project planning process. Customers can monitor the equipment's assembly and debugging progress online at any time. Once the equipment is accepted by the customer, they'll conduct an the exit inspection in accordance with the exit delivery process to ensure that the equipment can be quickly put into the customer's factory production process. We have an efficient record of equipment and data. All data about equipment and customers are stored in paper files as well as electronic files. The mold updating service could be utilized to produce drawings or to provide Customization. After-sales assistance is provided by our professional team.

To ensure stability and quality in product quality, we adhere to the concept of quality first as well as take other steps like Pipe processing machine of sources, monitoring the production process, and continual improvement. We will continue to adhere the quality-first principle in the near future, and will continue to improve our products and services in order to provide greater value to customers.

Suzhou VEDETTE, as a leading Pipe processing machine manufacturer in the market, puts the highest importance to technological innovation and investment in research and development, and continues to launch new products that compete to meet the increasingly diversified requirements of the market. We adhere to the quality of life, customer satisfaction as the primary objective and provide all the professional services covering pre-sales consulting, sales technical support, after-sales service, and ensuring that customers get the benefit of timely and professional technical assistance and solutions. Our products can be applied to a variety of industries. Suzhou VEDETTE which is a major manufacturer of pipe processing equipment is the most suitable choice for those who need to use it.

Suzhou Vedette Industrial Equipment Co., Ltd. was founded in 2011 and is located by the beautiful Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the manufacturing of equipment. With over a decade of expertise in the development, research and manufacturing of tube processing equipment as well as different types of custom-designed automation production lines, it is a national high-tech company that is involved in the design and manufacture of technologically automated and sophisticated equipment. As as of December 20, 2022, it had 31 utility model patents, and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, serving clients across the world. The company adheres to its corporate goal of offering quality products and services that add value to customers, and is committed to becoming a pioneer in the field of technological advancement for tube processing equipment within Pipe processing machine.