Ever watched someone bend a tube to make something like say, the frame of a bicycle or yard fence or even an exhaust pipe on your car? It’s fascinating to watch! These tubes must be precision bent to slide into each respective location just right. That is where a hydraulic tube bender comes in. It is a special tool which can bend these tubes precisely and conveniently to ensure they are perfectly fittable

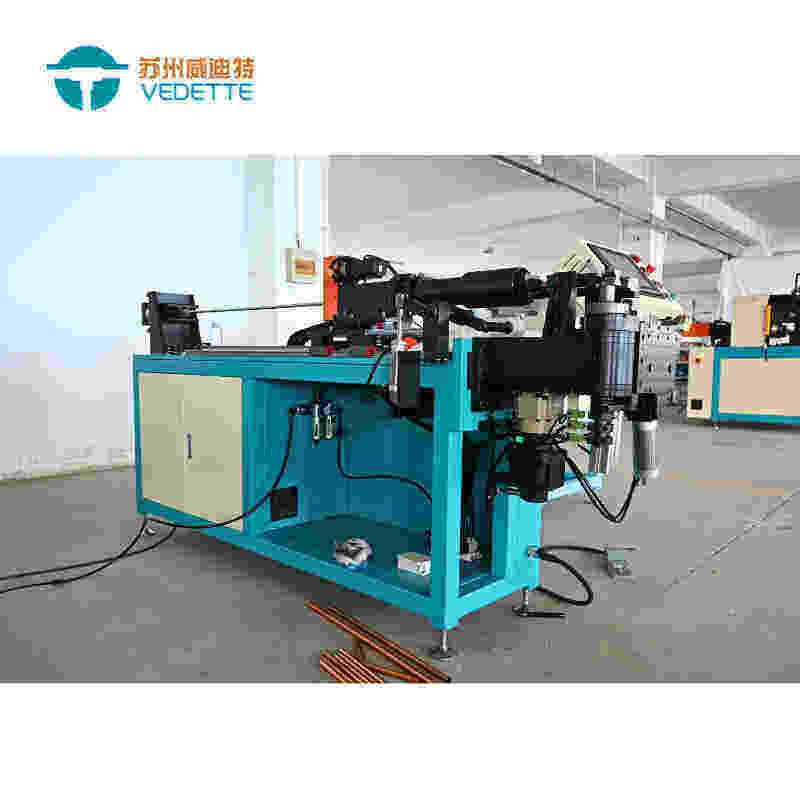

How does a Hydraulic tube bender work? I really like this technique as it bends the tubes without kinking them or causing any deformation. This escapes the physical stress large chamber benders need humans to operate! Waterline is quick and easy to bend, otherwise it would be a nightmare with manual benders as you could quite easily just create dents or uneven bends. But a Pipe bending machine Vedette provides exact, repeatable outcomes. That is to say, every corner looks good and feels like what it should.

The hydraulic tube bender lets you produce intricate shapes and designs straightforwardly. In certain industries where product fabrication necessitates the bending of tubes, this can be an invaluable skill to possess. A broad range of bends such as curves, angles and U-shapes can be produced by a hydraulic tube bender so the designer are no longer in need to keep it less complicated

These benders include an additional set of tools called dies. The printed design is different for every die, and it can be swapped out to cater a customer's preference. This allows a hydraulic tube bender to be tailored for different processing jobs. For this reason, hydraulic tube benders are essential in industries such as car production, airplane construction, and bridge building where to achieve accurate bending is extremely important.

By the storage of hydraulic technology allows to have a quality and efficient tube bending solutions. First Vedette Cutting machine saves time It requires less no of labors And second one The Result always good! A huge piston with enough pressure to bend the tube without causing any harm is present in hydraulic tube benders. That allows the operator to dial in pressure needed for a specific bend.

This not only makes the job faster and more manageable but also produces better bends, with smoother radii. The most typical models of the hydraulic tube bending machine are those that use liquid pressure to form the appropriate bend. It grips the tube that is then bent around it so does not move. The latter gives an even cleaner and nicer bend line that will make the end part look a lot better in comparison.

With these advanced features, the tool can produce tubes of identical size and shape which should simplifies assembly at a later stage. For example, it makes the Vedette Products work well and eliminates issues as gare insertion sets are adjusted for a good orientation providing improved comfort while wearing them with consistency being key to all of this. More the accuracy in manufacturing a product, higher is the level of trust and satisfaction generated among buyers.

Suzhou VEDETTE is a leading Hydraulic tube bender of pipe processing equipment in the field. It places great emphasis on technological innovation, research as well as development, and has launched new products that are competitive to meet the ever-changing demands of the market. We're committed to provide you with expert solutions that include pre-sales consulting as well as sales technical assistance and after-sales support. This ensures that our customers get prompt and efficient solutions. Our products are broadly applicable to different industries. Suzhou VEDETTE which is a major manufacturer of equipment for pipe processing is the best choice for users.

Hydraulic tube bender was founded in 2011 and is located close to the gorgeous Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the production of equipment. With more than a decade of expertise in the development, research and production of tube processing equipment and various kinds of custom automation production lines that are a national high-tech company that is involved in the development and production of technologically automated and intelligent equipment. As in December 2022 it has 31 utility model patents, and 10 equipment invention patents. The equipment is well-received both domestically and internationally, with clients across the world. The company abides by its corporate goal of offering valuable products and services for its customers and is dedicated to being a leader in the field of technological advancement for tube processing equipment in China.

Hydraulic tube bender ensure the highest quality and stability in the quality of our products We adhere to the principle of quality first as well as take other steps such as source control as well as monitoring the process of production, and continual improvement. In the future, we will continue to keep to the principle of quality first. We will continue to improve the level of products and services to bring more value to our customers.

Our company is manufacturing pipe processing automation equipment for more than 10 year and we have over 1,000 design schemes that are not standard. Hydraulic tube bender sales teams can customize services based on a thorough understanding of customer demands. The process of planning the project is followed to manufacture and test our equipment. Customers can follow the equipment's construction and debugging progress on the internet anytime. They will conduct an exit inspection following the strict process for delivering the exit after the equipment has been accepted to ensure the equipment can be quickly integrated into the factory production processes of the customer. We have an archive system for data and equipment system that is flawless. The customer's data equipment is saved both in the form of paper and electronic files. The mold updating service could be used to provide drawings or Customization. After-sales assistance is provided by our expert team.