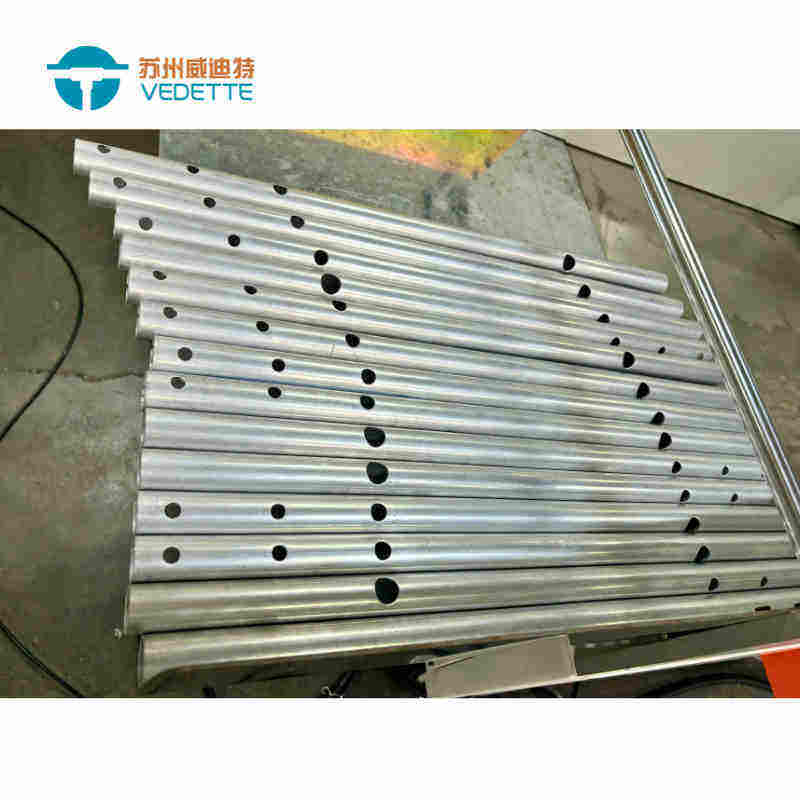

Need to create very precise tubes with holes in them? Would you like a free and efficient way to make a multi-bore capillary tube for your booster pump that doesn´t cost 345 euro. Well, then Vedette CNC tube punching machines are what you need. They are known for producing precise holes with very few errors, and they were built to be especially useful in that respect. When you use these machines, this is to say that products will be put in place always same dimension end very good quality. Thanks to the modern CNC Punching machine capabilities, you know every hole was made perfectly each and every time. You will not face any error issue at your tube products. This is because CNC tube punching machines will allow you to perform the work realiably, therefore making it automatic.

These are very useful devices for saving time and labor when manufacturing tubes, also providing substantial cost savings. Unfortunately, these machines can be automated to operate corresponding you would not require a large quantity of people aiding you. In turn, this results in lower production costs for you. With the help of Vedette CNC machines, you can get your work done quickly. You can then produce more products in less time than it would take to make them from scratch, but at a reduced cost overall. This is a great way to set your business up for success and ensure that you can outperform others in your industry. There is no doubt that tube punching has been made so much easier and more precise with CNC technology than it ever was before.

CNC tube punching machines are very versatile and can complete a wide variety of jobs. From these machines, you can punch holes and make notches or even create slots in tubes of all sizes and materials. CNC technology is excellent because it lets you adjust the settings on your machines to what I really need for each job. That way you can create unique products and stand out from the sea of other stuff on the market. This allows you to experiment and grow your product offering in new ways with these beautiful machines. CNC tube punching equipment and copper pipe punching machine Line for different sectors from HVAC to Automotive (car manufacturing), Construction, Manufacturing.

With the help of CNC tube punching machines you can ease your work and turn it to be more efficient. They can save you a ton of time by helping increase your productivity without sacrificing the quality in what you produce. You can program your machines to perform certain tasks with CNC technology, for example you wouldn't need to manually do everything. You can then focus on more essential aspects of your business while the machines take care of the bulk. You can also keep a closer eye on everything during the production process and make any changes as necessary. What helps the most in this, is your ability to keep track on progress and thus you make sure that all of your work gets done before time deadlines. Utilizing a single-shaft punching machine can help make your work more productive and efficient.

CNC punching technology can be said to have provided a new way of tube manufacturing. Machines to Make More Complex Shapes — You could use these machines to make shapes and designs that you may not have been able or would be very difficult manually. All of this allows for more complex, highly detailed designs to be produced on CNC tube punching machines and other equipment — something which was impossible even in fairly recent decades. With it you are able to build those special items that people actually desire, which will make your business unique in the market. Using Vedette Multi-spindle punching machine can help you to open up new ideas and avenues, that you might never have even considered beforehand. This is a game changer in the way tubes are made, and it can give you that head start to build your business.

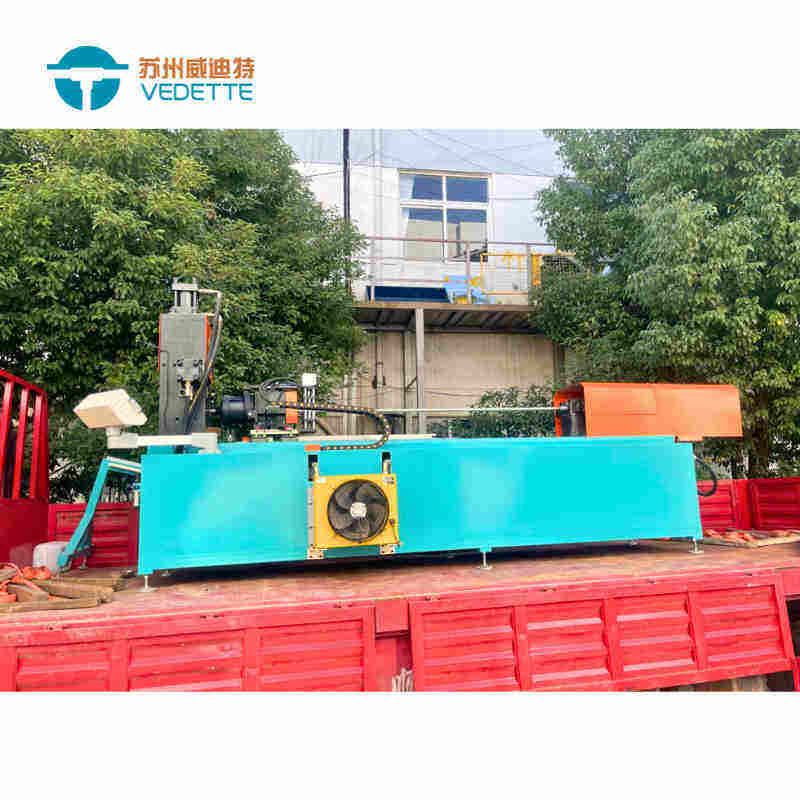

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an Cnc tube punching equipment importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.

Suzhou Vedette Industrial Equipment Co., Ltd., established in 2011, is located in the southwest of Suzhou, near the Cnc tube punching equipment, an innovation center in the manufacturing of Cnc tube punching equipment. It is a high-tech company that has more than 10 years of experience in research development, manufacturing and modifying automation production lines. At the time of its December 2022 launch, it had 31 utility model and 10 invention patents related to equipment. Its equipment is well-received nationally and internationally, with clients across the world. The company abides by its core mission of providing high-quality products and services to customers, and is committed to being a leader in the field of technological advancement for tube processing equipment in China.

To ensure stability and quality in product quality, we adhere to the concept of quality first as well as take other steps like Cnc tube punching equipment of sources, monitoring the production process, and continual improvement. We will continue to adhere the quality-first principle in the near future, and will continue to improve our products and services in order to provide greater value to customers.

Cnc tube punching equipment company is manufacturing pipe processing automation equipment for more than 10 year and we have more than 1,000 designs that are not conventional. Once we have a complete understanding of the requirements of our clients and requirements, our experienced sales team can tailor the services to meet your needs. The project planning process is followed to manufacture and debug our equipment. Customers can watch the equipment assembly and debugging progress online anytime. After the equipment is accepted by the customer, they'll conduct an exit inspections in complete accordance to the exit delivery procedure to ensure that the equipment is promptly incorporated into the customer's factory production tasks; We have a perfect data and equipment archiving system. The customer's equipment is preserved both in electronic and paper files. Mold updating can provide illustrations or Customization. After-sales support is provided by our experienced team.