You have heard about pipe bending if you are a metal worker. Pipe bending is a metal forming process in which metal pipes are bent to different angles and shapes. These shapes are important and are used in jobs, such as cars, airplanes and buildings. Once, pipe bending was a slow and laborious process. This was time-consuming and painstaking, the results not always satisfactory. However, CNC pipe benders have vastly sped this process up to make it more accurate, and even easier for metal workers.

CNC pipe bending technology revolutionized the way we bend pipes in the metalworking industry. Previously, workers would use their hands to align all angles and orientations of pipes by hand. This was a time-consuming job and often prone to mistakes. Even a slight error in the angle can lead to trouble later on. But, the advent of CNC pipe benders now automates the entire process of bending. It means it is completely machine done and way quicker and accurate outputs.

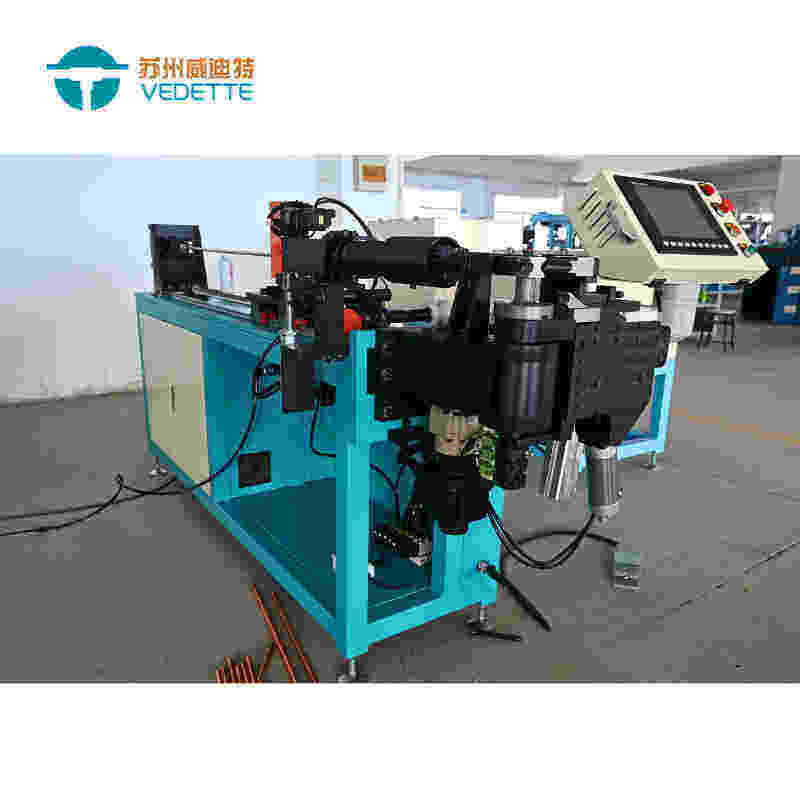

We provide CNC pipe benders with advanced software at Vedette. This unique software enables them to input very precise angles and directions for the bending needed for each job. After entering the information, the machine handles the rest. It rapidly and precisely bends the metal pipes into the molds that are needed. This automation allows our CNC pipe benders to achieve excellent results with minimal worker assistance. This enables workers to invest their time in other key tasks, rather than bending pipes all the time.

The improved precision offered by CNC pipe benders is one of the most prominent advantages of using them. Precision being essential in many industrial sectors, it becomes all the more imperative in sectors like aerospace and automotive industry for manufacturers. Through such industries, minor differences where the angle didn't apply correct, can raised serious problems that put in danger with the process of work or even with the function itself.

The pipe bends produced by Vedette CNC pipe benders are extremely accurate. Traditional pipe bending methods often do not come close to the level of accuracy our machines can achieve. Such high level of accuracy allows our customers to make better quality products with less mistakes. Higher customer satisfaction entails producing products and services with fewer mistakes. Contented customers tend to come back and order more, which is good news for any line of business.

Our CNC pipe benders automate the entire bend process, ensuring everything runs smoothly. The machines could bend multiple times in a row before workers had to step in. This allows our customers to produce more products in a shorter time frame. What this means is being able to do more in less time, which results in increased profitability. When businesses are able to run more efficiently they can save money and raise their profit margins.

Another advantage is that since the bending process is automated, there is also a lower possibility of human errors or inconsistencies. That ensures a better quality of the end product that meets the industry-standard requirements. Producing products correctly at first go leads to higher customer satisfaction. By ensuring customers are satisfied with the quality of their products, they can return for more orders increasing sales and making our customers more profitable.

Our company is manufacturing pipe processing automation equipment for more than 10 year and we have over 1,000 design schemes that are not standard. cnc pipe bender sales teams can customize services based on a thorough understanding of customer demands. The process of planning the project is followed to manufacture and test our equipment. Customers can follow the equipment's construction and debugging progress on the internet anytime. They will conduct an exit inspection following the strict process for delivering the exit after the equipment has been accepted to ensure the equipment can be quickly integrated into the factory production processes of the customer. We have an archive system for data and equipment system that is flawless. The customer's data equipment is saved both in the form of paper and electronic files. The mold updating service could be used to provide drawings or Customization. After-sales assistance is provided by our expert team.

To ensure consistency and excellence in the quality of our products, we cnc pipe bender to the concept of quality first as well as take other steps such as source control, monitoring the production process as well as continuous improvement. We will keep adhering to this principle in the near future, and will continue to improve our services and products to offer greater value to our customers.

Suzhou VEDETTE, as a prominent manufacturer of pipe processing equipment in the market, puts an cnc pipe bender importance to technological advancement as well as research and development investments, and continues to launch new products with market competitiveness to meet the ever-changing needs of the market. We place high-quality of life, and the customer satisfaction as the primary objective and provide an array of high-quality services that include pre-sales consultation, sales technical support, after-sales maintenance and to ensure that customers have access to of professional and timely technical assistance and solutions. Our products can be applied to various industries. For the users who need pipe processing equipment Suzhou VEDETTE is definitely the most reliable choice.

cnc pipe bender was founded in 2011 and is located close to the gorgeous Taihu Lake in the southwest of Suzhou, a hub of technological innovation in the production of equipment. With more than a decade of expertise in the development, research and production of tube processing equipment and various kinds of custom automation production lines that are a national high-tech company that is involved in the development and production of technologically automated and intelligent equipment. As in December 2022 it has 31 utility model patents, and 10 equipment invention patents. The equipment is well-received both domestically and internationally, with clients across the world. The company abides by its corporate goal of offering valuable products and services for its customers and is dedicated to being a leader in the field of technological advancement for tube processing equipment in China.